- Product Details

- {{item.text}}

Quick Details

-

Applicable Industries:

-

Plastic bag making

-

Place of Origin:

-

China

-

Model Number:

-

JQ1000

-

Voltage:

-

220V 50HZ or customized

-

Dimension(L*W*H):

-

5.5m x 2.8m x 1.3m

-

Weight:

-

1800 KG

-

Certification:

-

CE

Quick Details

-

Machine Type:

-

Bag Forming Machine

-

Bag Type:

-

Side-sealed Plastic Bags

-

Material:

-

Plastic

-

Applicable Industries:

-

Plastic bag making

-

Place of Origin:

-

China

-

Model Number:

-

JQ1000

-

Voltage:

-

220V 50HZ or customized

-

Dimension(L*W*H):

-

5.5m x 2.8m x 1.3m

-

Weight:

-

1800 KG

-

Certification:

-

CE

Product Description

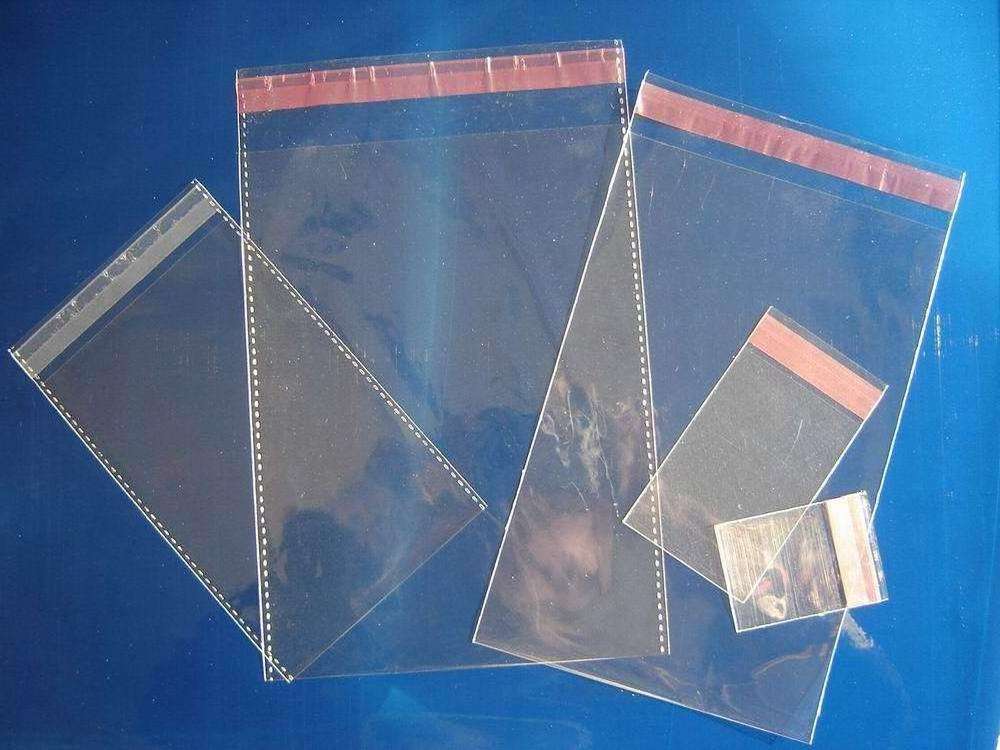

Sample Bag Photos

OPP bags

Dot side sealing

Adhesive tape on lip of mouth

Blown PE side sealed bag

Plain side sealing

Adhesive tape on the lip of mouth

OPP bags

Plain side sealing

Butterfly Hanger Hole

Side-sealed Shopping bag

Bottom gusset

Side sealing

Made of PE film

D-cut Side sealing Shopping bag

D-cut Hole Handle at top

Top folded inside, so four layers at top for strength purpose

Top folded inside, so there is longitudinal sealing

Side-seal Bread Bags

Made of PE or OPP film

Side-sealed

Transparent

Products Description

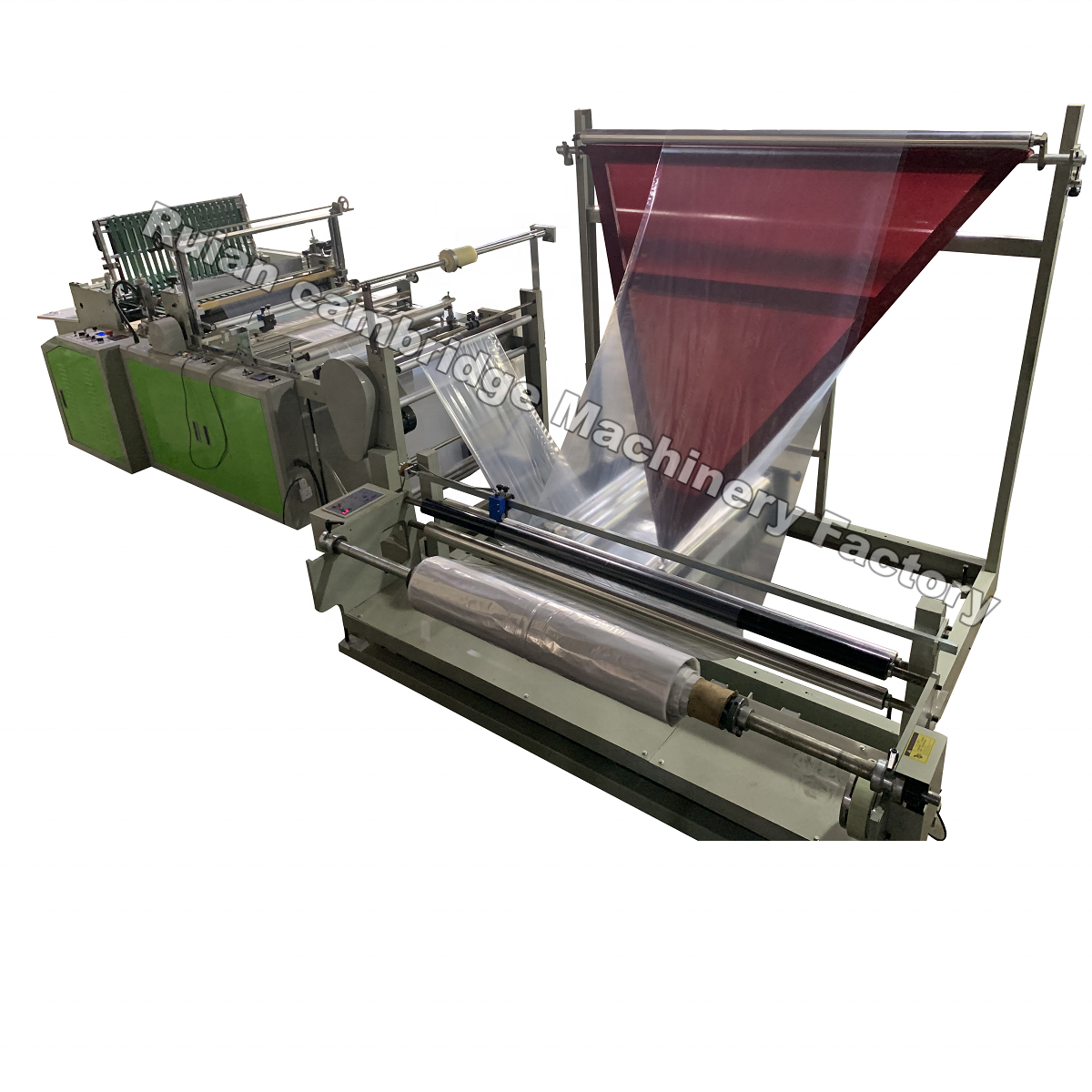

PE/OPP/PP Plastic Bags Side Hot Cutting Seal Bag Making Machinery Machine

Main Features:

1. Unwinder with auto edge guide and magnetic powder brake

2. With tube film cutter

3. Back film feeding with dancing roller plus DC or AC motor drive

4. Hot cutting bar with two edges, one edge for PE, and the other edge for PP/OPP/BOPP

5. Belt conveyor to send out the ready bags one by one, and stack them at the table.

6. Small unwinder for adhesive tape roll, so it can put the tape at the lip of bag mouth

7. Two transverse Sealing bars to seal two lines at the middle of the side sealing bag

8. Servo motor for bag length control and for different cutting speed adjusting

9. Touch screen computer for set different parameters

10. With bottom gusset former

11. With two hole punchers

Options:

a. Dot sealing cutting bar

b. Butterfly Shape Hanger Puncher

c. Ultrasonic welding unit

d.

Inline triangle folder, which will fold the sheet before hot cutting.

e. Round hold puncher, 6 mm, 8 mm or 10 mm

f. D cut Puncher

Specification:

Hot Searches