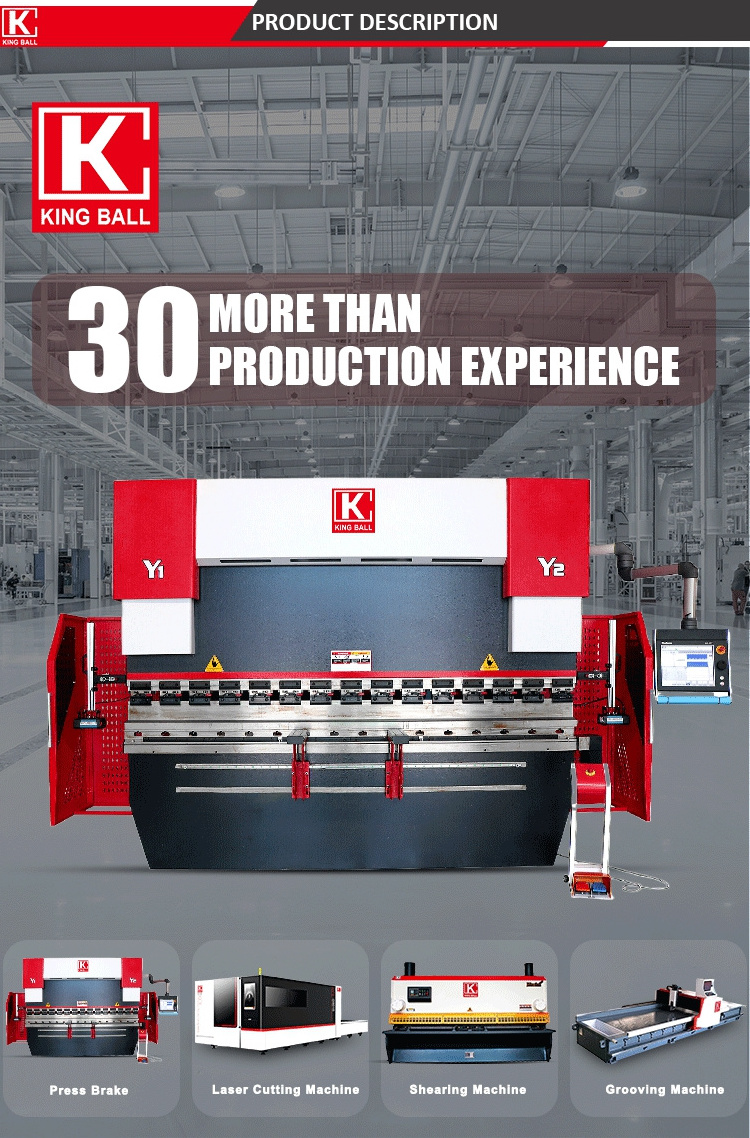

Main functions and features

●

Overall welded and processed structure.

●

Save electricity, Compared with the traditional transmission device, the electricity consumption is 50%.

●

Within one stroke, bending pressure can be controlled at random point, repeatability precision±0.01, parallelism 0.02,high working effective, can improve 30%.

●

The noise is reduced and the machine is quieter.

●

Save oil, Hydraulic fluid use is very small, only for the traditional 50 %

●

Lower worktable has crowning device to anti deflection & upper tool has wedge compensation device.

●

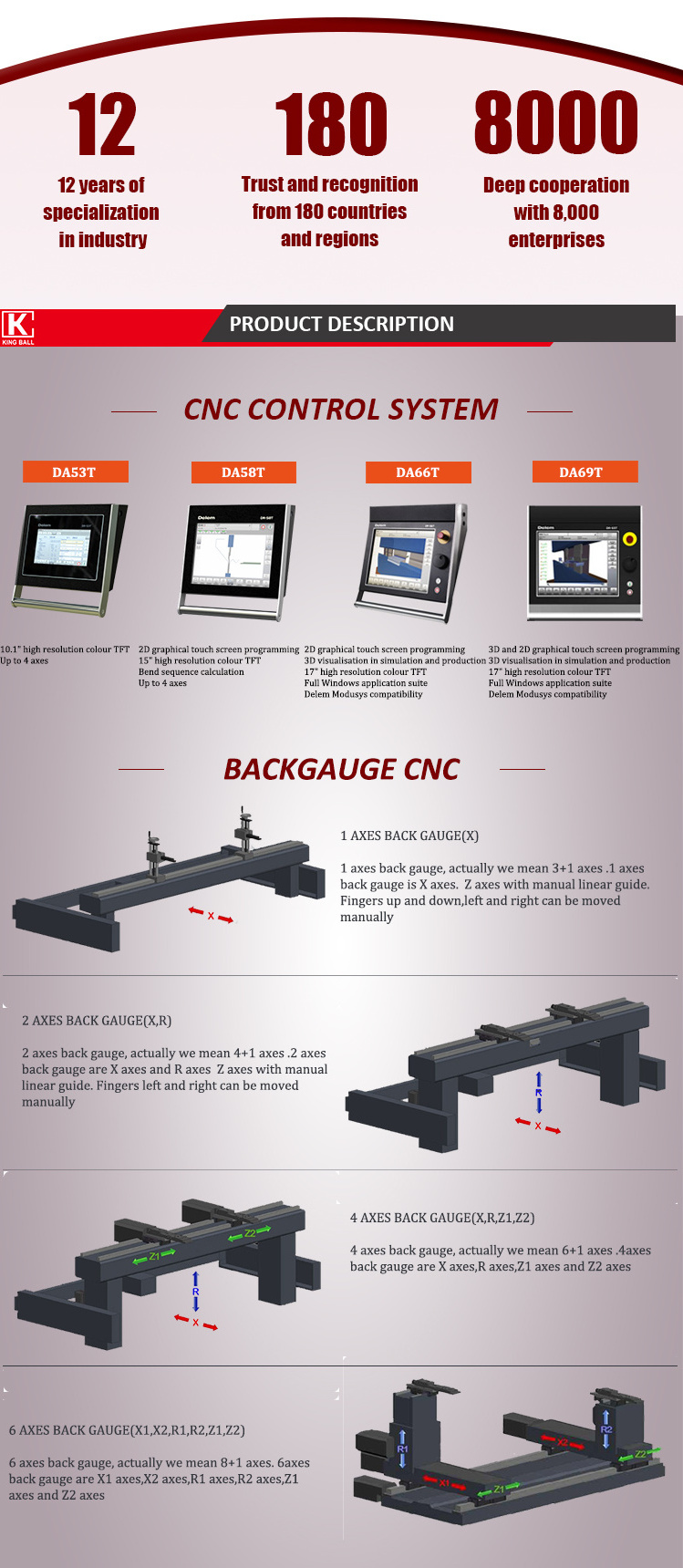

Delem CNC control system, grating ruler, Rexroth hydraulics, servo motors and other accessories of famous brand are installed for perfect machine performance.

●

Ram stroke(Y1, Y2),backgauge (X,R,Z) are controlled by CNC controller while ball screw and linear guide rail installed for high repeatability precision.

●

Imported ball screw and linear guide are used for rear stopper, to ensure the positioning precision of rear stopper, for processing precision of machine to be higher.