- Product Details

- {{item.text}}

Quick Details

-

Description:

-

High impact barrelled water tank clean Spray Nozzle

-

Material:

-

SS 304

-

Thread Size:

-

1/2" female thread

-

Working pressure:

-

0-120 bar

-

Spray coverage:

-

360 degree

-

Cleaning diameter:

-

1000MM

-

Spray pattern:

-

Flat fan

-

Product name:

-

Bottle Tank Cleaning Nozzle

-

Application:

-

Barrelled water washing

Quick Details

-

Weight (KG):

-

0.4

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

XR

-

Description:

-

High impact barrelled water tank clean Spray Nozzle

-

Material:

-

SS 304

-

Thread Size:

-

1/2" female thread

-

Working pressure:

-

0-120 bar

-

Spray coverage:

-

360 degree

-

Cleaning diameter:

-

1000MM

-

Spray pattern:

-

Flat fan

-

Product name:

-

Bottle Tank Cleaning Nozzle

-

Application:

-

Barrelled water washing

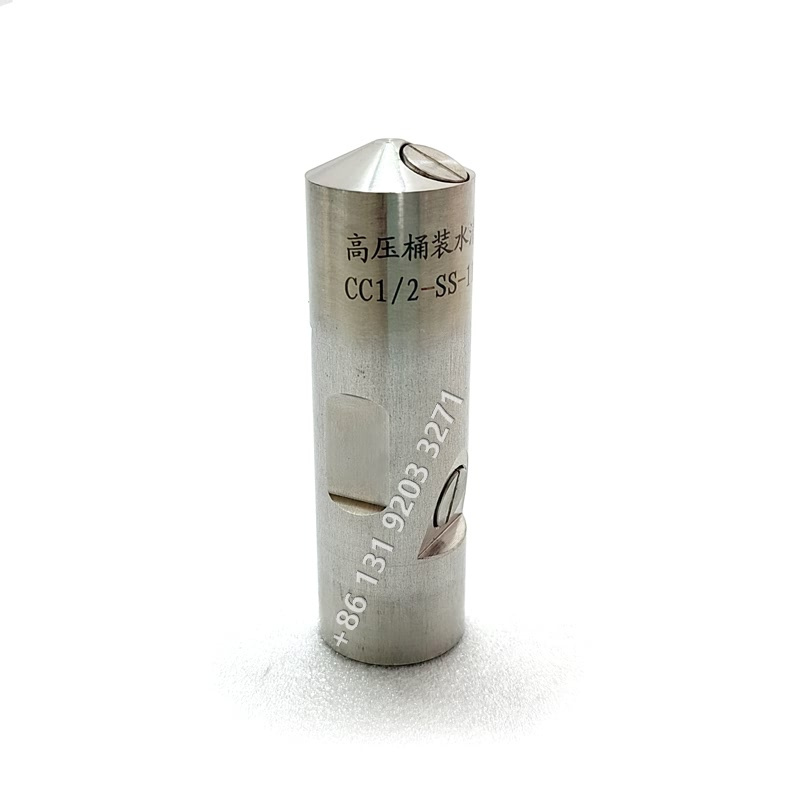

Bottled Water High Pressure Cleaning Nozzle Water Dispenser Fixed Inner Wall Washing Spray Nozzle No Contact Water Jet Sprayer

1. Product name: High Impact Barrelled Water Tank Clean Spray Nozzle

2. Material: Stainless Steel

3. Thread size: 1/2" female thread

4. Working pressure: 0-120 bar

5. Spray coverage: 360 degree

6. Cleaning diameter: 1000MM

7. Spray pattern: Flat fan

8. Description: Rotating tank washing spray nozzle

9. Application: Washing / cleaning

10. Drinking mineral water barrel cleaning nozzle tank cleaning container cleaning

Design Features:

1. Provide comprehensive spray coverage and no dead corners for cleaning of the middle and middle neck of the complete bucket bottom. The nozzle material is stainless steel for maximum wear life.

2. All internal surfaces are completely covered by the spray track, so the nozzles can provide effective internal cleaning of small bottles, cans and barrels;

3. The main body of the nozzle is made of strong corrosion-resistant material to achieve maximum wear life and realize high-pressure cleaning, with the pressure reaching 0.5MPa~80MPa;

4. The flow fan-shaped spray nozzle can achieve the maximum wear life for cleaning small containers and achieve high-pressure cleaning, with a pressure of up to 80MPa.

1. Reaction kettle cleaning

2. Pharmaceutical barrels cleaning

3. Dry powder tank cleaning

4. Freeze-drying machine cleaning

5. Sterilization tank cleaning,

6. Washing the flow slurry tank

7. Mixing barrel cleaning

Product Parameter