- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

220V50HZ/380V50HZ

-

Power:

-

11.5KW

-

Dimension(L*W*H):

-

1750*1350*1850 mm

-

Weight:

-

3800 kg

-

Product name:

-

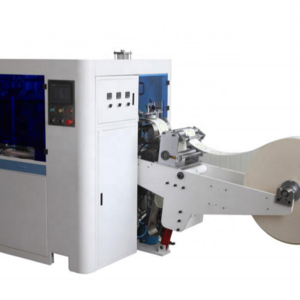

Paper Cup Making Machine

-

Raw materia:

-

Single PE coating paper

-

Top mouth diameter:

-

60mm-90mm

-

Bottom depth:

-

5mm-10mm

-

Main motor power:

-

1.5KW

-

Paper thickness:

-

160-300gsm

-

Bottom diameter:

-

40mm-70mm

-

Height:

-

60mm-180mm

-

Cup size:

-

6-16oz,16-22oz

-

Speed:

-

60-90pcs/min

Quick Details

-

Production Capacity:

-

60-90pcs/min

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

YUGONG

-

Voltage:

-

220V50HZ/380V50HZ

-

Power:

-

11.5KW

-

Dimension(L*W*H):

-

1750*1350*1850 mm

-

Weight:

-

3800 kg

-

Product name:

-

Paper Cup Making Machine

-

Raw materia:

-

Single PE coating paper

-

Top mouth diameter:

-

60mm-90mm

-

Bottom depth:

-

5mm-10mm

-

Main motor power:

-

1.5KW

-

Paper thickness:

-

160-300gsm

-

Bottom diameter:

-

40mm-70mm

-

Height:

-

60mm-180mm

-

Cup size:

-

6-16oz,16-22oz

-

Speed:

-

60-90pcs/min

Product Description

Smart middle speed paper cup forming machine is provided with advantages of high performance,high efficiency and high quality.The overall steel plate machine body and oil-spraying lubrication system ensures normal and stable long-term operation of the equipment.

High Efficiency and Energy Conservation:

Advanced high-precision cylindrical cam driving unit working with gear drive system make sure the precisely working of every station.

Bottom paper feeding controlled by servo tracking system,and raw material paper can be saved effectively.

Foreign Technical and Made in China:

Paper bottom heating system(Switzerland Leister)uses 2 steps flameless heating.

Every step in production is monitored by photocell (Japan Omron)and be reported.

User-friendly Design:

The function of machine is controlled by human-computer interface and PLC system.

Manual operation can be replaced by automatic paper cup counting and collection table with appropriate setting.

High Efficiency and Energy Conservation:

Advanced high-precision cylindrical cam driving unit working with gear drive system make sure the precisely working of every station.

Bottom paper feeding controlled by servo tracking system,and raw material paper can be saved effectively.

Foreign Technical and Made in China:

Paper bottom heating system(Switzerland Leister)uses 2 steps flameless heating.

Every step in production is monitored by photocell (Japan Omron)and be reported.

User-friendly Design:

The function of machine is controlled by human-computer interface and PLC system.

Manual operation can be replaced by automatic paper cup counting and collection table with appropriate setting.

Specification

|

Cup size

|

6~16oz(outside diameter ofa cup 60-90mm,outside diameter of bottom

50~70mm,height of cup 50~135mm,depth of bottom 5~10mm) |

|

Rated speed

|

90-110pcs/min

|

|

Main motor power

|

2.2KW

|

|

Electro thermal power

|

8.6/13.2KW

|

|

Air source

|

0.6m/min;0.6MPa customer-owned

|

|

Applical base paper

|

190~350g/(single or double PE coating paper)

|

|

Weight

|

3.8T

|

|

Main size

|

2700*1500*1800mm

|

|

Paper cup collector size

|

1150*850*2000mm

|

|

Actual power consumption

|

7.5KW

|

|

Remark

|

The paper thickness error margin is ±0.05mm for the same set of mould

|

Product Detail Presentation

Finished Product Display

Hot Searches