The dry powder mixer is suitable for mixing various dry powder and fine granular materials (such as: putty powder, plaster, dry powder mortar, colored cement, various mineral powders, chemical materials, organic fertilizers, etc.).

- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

Qichen

-

Voltage:

-

220/380V

-

Power:

-

15kw

-

Dimension(L*W*H):

-

referring to drawing

-

Weight:

-

1800 kg

-

Features:

-

powder, granule mixing

-

Product name:

-

Dry Mortar Production Plant Mini Mortar Mixer

-

Batching and weighting:

-

Manual+simple Automatic

-

Capacity:

-

1-8 T/h

-

Mixer Type:

-

Horizontal Spiral Ribbon Mixer

-

Advantage:

-

High Output Lowcost

-

Automatic:

-

Semi-automatic Wall Putty Making

-

Packaging:

-

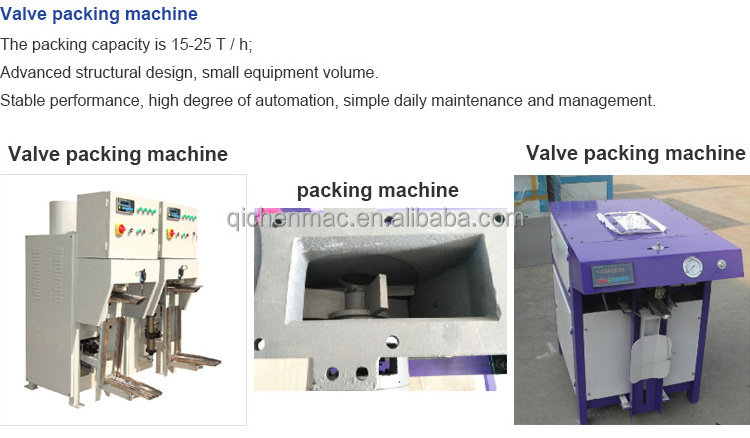

Valve Prot Packaging

-

Mixing time:

-

5-8 Mintues

-

Control system:

-

Electric Control Box

-

Brand:

-

QIC

Quick Details

-

Marketing Type:

-

New Product 2022

-

Application:

-

industry

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Qichen

-

Voltage:

-

220/380V

-

Power:

-

15kw

-

Dimension(L*W*H):

-

referring to drawing

-

Weight:

-

1800 kg

-

Features:

-

powder, granule mixing

-

Product name:

-

Dry Mortar Production Plant Mini Mortar Mixer

-

Batching and weighting:

-

Manual+simple Automatic

-

Capacity:

-

1-8 T/h

-

Mixer Type:

-

Horizontal Spiral Ribbon Mixer

-

Advantage:

-

High Output Lowcost

-

Automatic:

-

Semi-automatic Wall Putty Making

-

Packaging:

-

Valve Prot Packaging

-

Mixing time:

-

5-8 Mintues

-

Control system:

-

Electric Control Box

-

Brand:

-

QIC

Product Overview

QIC Simple Dry Mortar Production Line 3-4 T/H Tile Adhesive Mix Making Machine

The dry powder mortar production line is a new type of high-efficiency mixing equipment, which is widely used in putty paste, real stone paint, dry powder, putty, medicine, food, chemicals, feed, ceramics, refractories, etc. industries. The main mechanism of the horizontal ribbon mixer is the shearing effect of the ribbon. Through the high-speed rotation of the mixing shaft, the horizontal multi-spiral belt mixer enables the inner and outer spiral belts to turn the material in a larger range. Through the above-mentioned movement, the materials are quickly and uniformly mixed in a short time.

PRODUCT SPECIFICATIONS

|

Item

|

Data

|

|

Capacity

|

3-5t/h

|

|

Mixer power

|

7.5kw

|

|

First conveyor diameter

|

165mm

|

|

First conveyor length

|

3.2m

|

|

Second conveyor diameter

|

165mm

|

|

Second conveyor length

|

2.8m

|

|

Power

|

3kw

|

|

Packing

|

10-50kg/bag

|

PRODUCT CONFIGURATION

Dry Mortar Mixer

The dry powder mixer can work independently from a vertical mixer, and can realize feeding-stirring-packaging together with conveyors, storage tanks, and electronic metering automatic packaging machines (suitable for valve pockets, saving 3-4 workers and significantly improving production efficiency).

Successful Project

Product packaging

Why Choose Us

Pre-sales Service

1) Inquiry and consulting support.

2) Sample testing support.

3) View our factory.

4) More than 95% of the timely response rate, timely response to customer questions.

After-sales Service

1) Training how to install and use the machine.

2) Engineers available to service machinery overseas.

3) Use online contact methods to provide online services to customers.

FAQ

Cement Glue/Putty Powder Dry Mortar Mix Production Line Machinery 3-4T/H Tile Adhesive Making Mixing Machine

Cement Glue/Putty Powder Dry Mortar Mix Production Line Machinery 3-4T/H Tile Adhesive Making Mixing Machine

Cement Glue/Putty Powder Dry Mortar Mix Production Line Machinery 3-4T/H Tile Adhesive Making Mixing Machine

Cement Glue/Putty Powder Dry Mortar Mix Production Line Machinery 3-4T/H Tile Adhesive Making Mixing Machine

Cement Glue/Putty Powder Dry Mortar Mix Production Line Machinery 3-4T/H Tile Adhesive Making Mixing Machine

Cement Glue/Putty Powder Dry Mortar Mix Production Line Machinery 3-4T/H Tile Adhesive Making Mixing Machine

Hot Searches