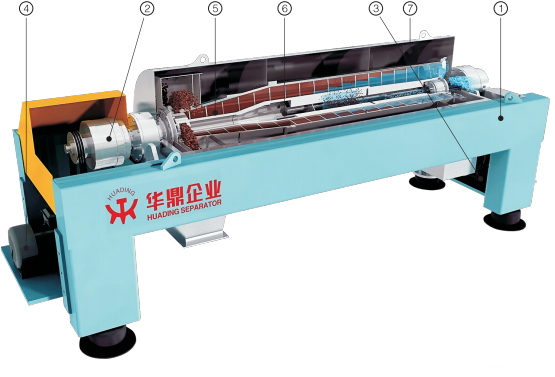

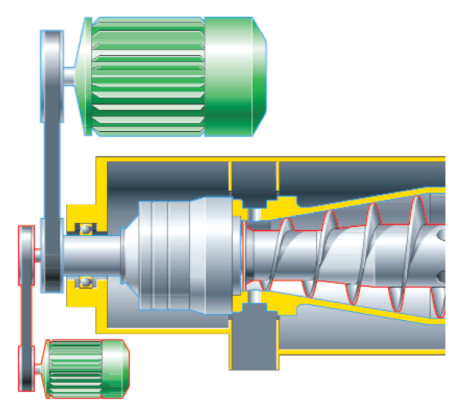

2. Gearbox

3. Primary motor

4. Secondary motor

5. Bowl

6. Screw

7. Hood