Anhui Runbang heavy Industry Machinery Co.,LTD

- Product Details

- {{item.text}}

Quick Details

-

The material yield strength:

-

Mild steel,≤245MPa

-

Bending maximum thickness:

-

6mm, stainless steel 3mm

-

Bending maximum width:

-

2000mm lenth plate bending

-

The remaining straight edge length:

-

2 times thickness

-

Bending speed:

-

About 4.5m/min

-

Top roll diameter:

-

210mm

-

Bottom roll diameter:

-

180mm

-

Side roll diameter:

-

150mm

-

Main power:

-

5.5 kw

Quick Details

-

Place of Origin:

-

Anhui, China

-

Brand Name:

-

RBQLTY

-

After-sales Service Provided:

-

Engineers available to service machinery overseas, Free spare parts, Online support, Field installation, commissioning and training, Video technical support

-

The material yield strength:

-

Mild steel,≤245MPa

-

Bending maximum thickness:

-

6mm, stainless steel 3mm

-

Bending maximum width:

-

2000mm lenth plate bending

-

The remaining straight edge length:

-

2 times thickness

-

Bending speed:

-

About 4.5m/min

-

Top roll diameter:

-

210mm

-

Bottom roll diameter:

-

180mm

-

Side roll diameter:

-

150mm

-

Main power:

-

5.5 kw

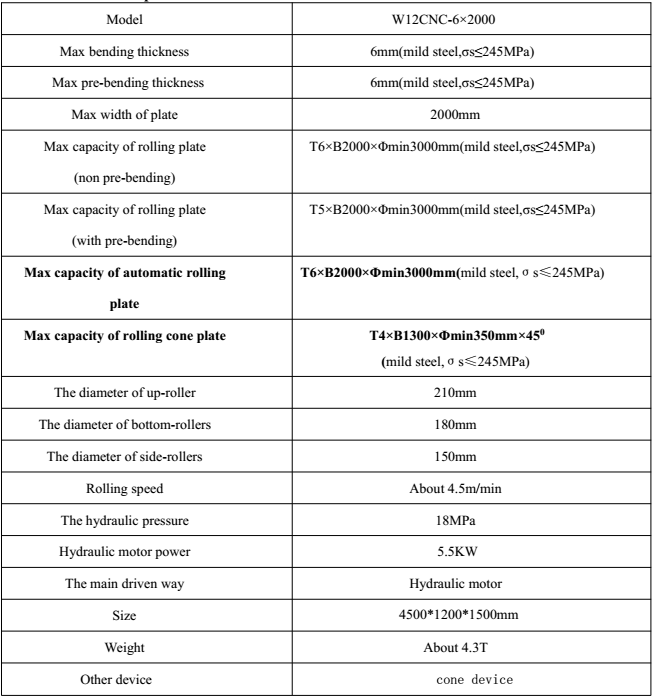

cnc 4 roller plate small rolling machine for stainless steel cone forming

Full hydraulic four-roll bending machine is hydraulic equipment in advanced and reliable technology architecture, with sufficient rigidity, and other key parts of the work roll for reasonable selection, precision manufacturing, high-performance, precision long retention period for long-term continuous processing, stable and reliable operation control, simple operation, is a high-precision, high efficiency in rolled sheet metal with unique advanced equipment.

The four roll bending machine is suitable for bending work of sheet metal. It can roll round, arc and tapered workpiece in a certain range, and has prebending function at the end of the board. The remaining straight side is small and the working efficiency is high, and the metal plate can be roughly leveled on the machine.

Compared with 3 roller bending machine :

1. Full CNC control when rolling coiling block;

2. High bending precision;

3. Improve work efficiency, save prdoction time and labor--save cost;

4.Can do cones with smaller diameter.

Main Features

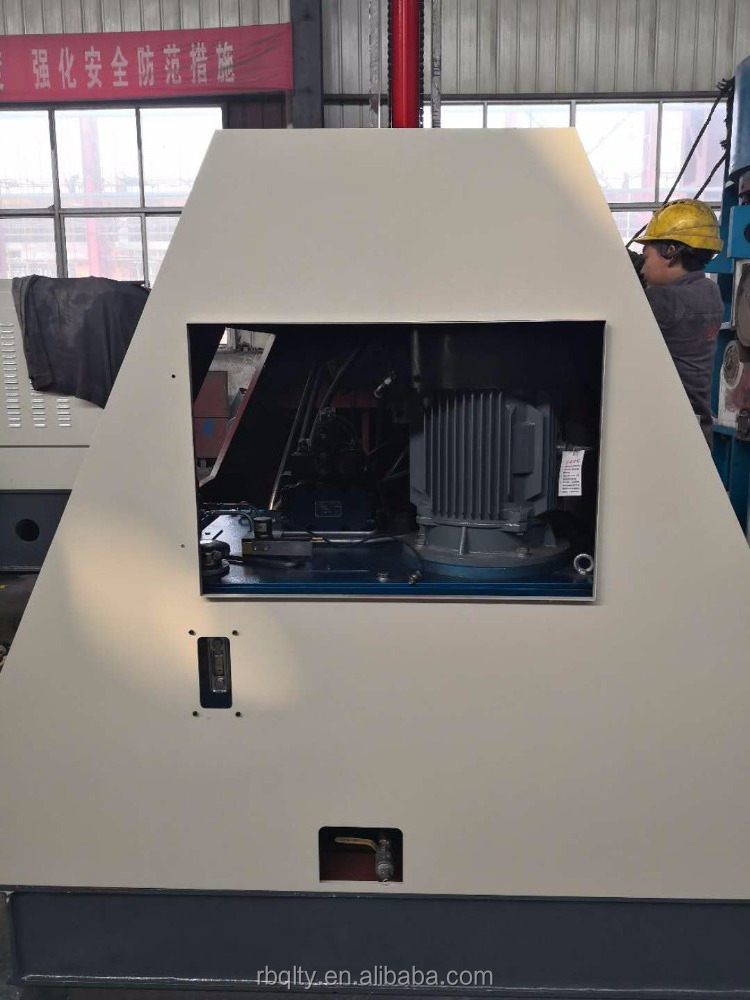

The machine belongs to the hydraulic type four-roll bending machine for steel plate at room temperature to roll into a cylinder shape.

The top roll can be fixed, and bottom roll and both side rolls can be moved up and down both sides of the roll.

Top and bottom roll are main driven rolls through its rotation torque to provide a sheet roll, and both sides of the roll are passive roll.

For pre-bending, the top and bottom roll are holding the plate, and side roll lift to deform the panels to achieve.

Work and lift function are hydraulically driven.

It is easy roll-circular cylindrical and the tapered barrel shape capacity.

To facilitate the cone rolling, this device can roll and tilt adjustment for bottom roll and both side roll.

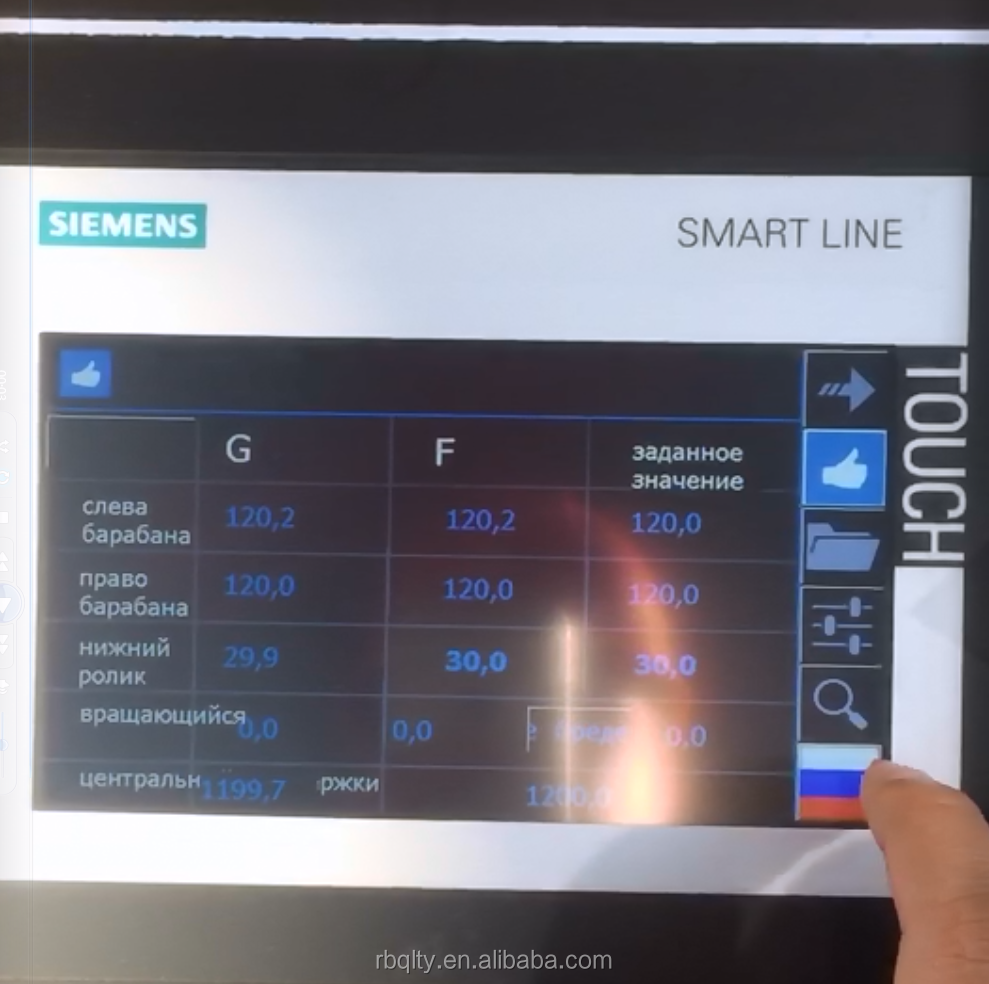

Siemens motor and Yifa hydraulic system

Joint detail

pressure gage-show clearly the working pressure

The auxiliary transmission mechanism;

Rolling machine base-weld firmly+accurate grinding

Roller surface with chroming treatment

Automatic bending principle and process:

With Siemens control system, language can be customized as your need: English/Russian/Spain, and so on

Products show:

*Expert in kinds of sheet metal processing machines, like bending machine, shearing machine, iron worker, hydraulic press, punching machine, duct manufacturing auto line, cutting machine and so on

*With an expert team in R&D for more than 20 years, occupied the work shop of over 30,000 square meters, runbang is able to support you with best quality machines

1. Technical solutions: we can provide technical solutions within one day.

2. Online video: show you machine working video in factory . ( update every month)

3. Installation service: this is available with all of our machines,

4. Training service: Our technician will teach you how to use our machines. As well, you may send your technician to our company to learn how to operate machines.

5. Quality guarantee: 1 year warranty, we provide lifetime service. We arrange final test before shipment, After making sure machine is the best performance, then make shipments.

6. 100% response rate: we will reply your question within 12 hours.

Packing Details : Normal package is plastic film, wooden case package could be discussed;

Delivery Times : About 15 working days after all details confirmed and deposit received;

Shpping Forwarder : Competitve price will provide from our longterm cooperation forwarder.

Also we could contact your forwarder and arrange everything well for you.

FAQ

*We have

our own factory

and brand; Our machines can match all the CE standard or more strict ones.

*Quality assurance: 2 years warranty and

100% quality inspection

before packing.

*Service:Impeccable after-sale service, and all your problem will be solved within 24 hours.

*Price: Can be negotiable according to the qty.

*MOQ:1 set.

*Howtovisit:You can fly to NanJing LuKou airport directly,you can also take high- speed train to Nanjing South Station from other city in China.We will pick you up in the airport or Train station.