- Product Details

- {{item.text}}

Quick Details

-

Throat Depth (mm):

-

350 mm

-

Width of Working Table (mm):

-

200 mm

-

Place of Origin:

-

Anhui, China

-

Brand Name:

-

Durmapress

-

Weight (KG):

-

7000

-

Motor Power (kw):

-

7.5 kw

-

Raw Material:

-

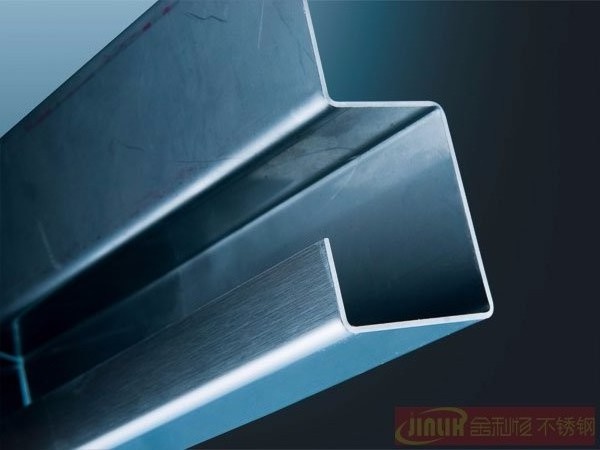

Sheet / Plate Rolling

-

Color:

-

red, white , blue ,optional

-

Certification:

-

ISO 9001:2000, CE

-

Price:

-

competitive

-

Motor:

-

Siemens

-

name:

-

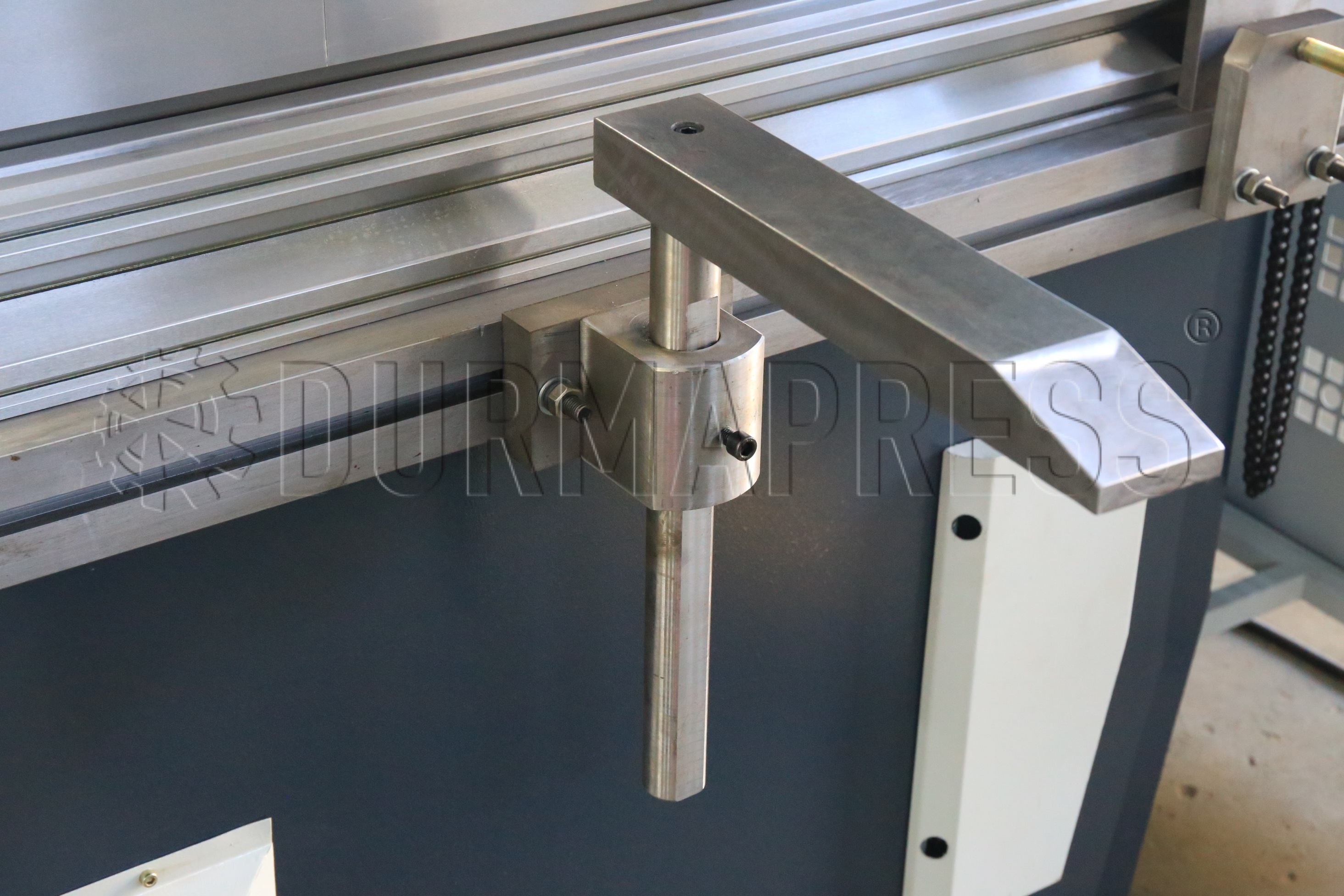

hydraulic cnc press brake

-

Power:

-

Hydraulic

Quick Details

-

Machine Type:

-

Torsion Bar

-

Length of Working Table (mm):

-

2500

-

Slider Stroke (mm):

-

150 mm

-

Throat Depth (mm):

-

350 mm

-

Width of Working Table (mm):

-

200 mm

-

Place of Origin:

-

Anhui, China

-

Brand Name:

-

Durmapress

-

Weight (KG):

-

7000

-

Motor Power (kw):

-

7.5 kw

-

Raw Material:

-

Sheet / Plate Rolling

-

Color:

-

red, white , blue ,optional

-

Certification:

-

ISO 9001:2000, CE

-

Price:

-

competitive

-

Motor:

-

Siemens

-

name:

-

hydraulic cnc press brake

-

Power:

-

Hydraulic

CNC Press Brake

software of CAD/CAE/CAM to fully guarantee the intensity and rigidity of all the components.

2. KINGWELL engineers utilize parametric 3D SolidWorks using FEM & DOE analysis as well as static and mechanism analysis.

3. All machine body is total monoblock welded assembly by high quality steels . After welding procedure, the machine body will be

milled to ensure the balance and precision.

4. Mechanical synchronous mechanism and the complex compensation are designed so as to raise the work pieces precision.

5. Adopt integrated hydraulic system, more reliable and easy for maintenance.

6. The stroke and distance of the backgauge is adjusted by the motor and is well adjusted by hand,the adjustment is displayed by

digital meters

7. Inch, single, continuous operation mode being designed for the machine and reversing and maintain time can be controlled by the

time relays

8. Humanistic concern security design in all details and also the scientific details through KINGWELL standard.

|

Model

|

|

WC67K 125T 2500

|

|

||

|

Pressing force

|

|

1250

|

KN

|

||

|

Working length

|

|

2500

|

MM

|

||

|

Distance between uprights

|

|

2000

|

MM

|

||

|

Stroke

|

|

350

|

MM

|

||

|

Max opening height

|

|

410

|

MM

|

||

|

Table width

|

|

200

|

MM

|

||

|

Motor

|

|

7.5

|

KW

|

||

|

Overall Dimension

|

|

3800*1650*2370

|

MM

|

||

Main Configuration

-Powered Depth Y-axis&Back gauge X-axis

-Servo control X,Yaxis

-HIWIN Ball screws &Polished rod with 0.05mm accuracy

-Plate Support Arms

-Telemecanique/Schneider E lectrics

-Germany Bosch-Rexroth Hydraulic

-Germany Siemens Main Motor

-Hydraulic &Electrical overload protection

Safety Equipment:

Safety Standards(2006/42/EC)

1.EN 12622:2009+a1:2003

2.EN ISO 12100:20110

3.EN 60204-1:2006+A1:2009

-BUS mode control servo system

-Stock counter

-Program memory of up to 40 programs

-up to 25 steps per program

-one side positioning

-retract function

-mm/inch

-Chinese/English

Our Service

Installation Services are available with all Our machines. We dispatch technician to customer's factory for installation and

preoperation of machines. ( Customers only need to pay the airfare and hotel )

2.Training Service

Our technician is available to your factory and offer training of how to use our machines. As well, you may send your technician

to our company to learn how to operate machines.

3.Quality Guarantee

We guarantee the quality of machine (e.g. processing speed and working performance is the same as the data of samples making). We sign the agreement with detailed technical data. Machine warranty is 5 years.

Q: How to get a accurate quotation from us ?

A:Please provide us the details of material , max thickness and max width .

Q:Can you do OEM service ?

A:Yes, we can. your design is accepted , your own logo can be used on the machine.

Q:What's the shipping cost from china to your country ?

A:We can send machine to your port or door address by sea or airplane. please kindly tell us your nearest port or address with postcode. we have reliable shipping agent to insure the safe convenient and time delivery.

Q:Do you accept LC payment ?

A:Yes, normally our payment is 30%+70% T/T ,LC payment is also acceptable

Q:How to operate this machine ?

A:Video line of our factory or we send you the video directly.

Q:What about commissioning service ?

A: We can offer commissioning service , the buyer need to afford plane tickets.

Q:Do you offer teaching & training ?

A:Training at supplier's plant