- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

Tongrui

-

Voltage:

-

380V 50HZ 3P (Customizable), 380v/50hz/3phrase( or according to customers')

-

Power:

-

38-285KW

-

Dimension(L*W*H):

-

Model Choose

-

Weight:

-

7000 kg

-

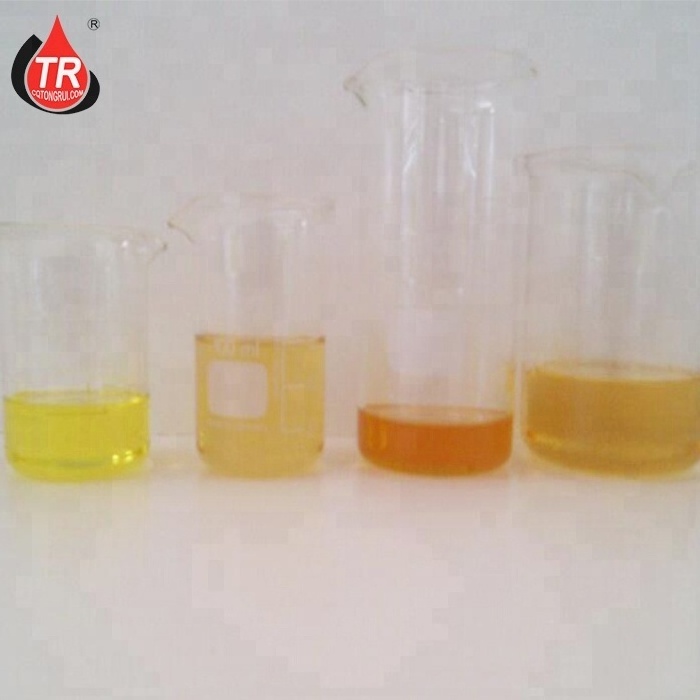

Color after treatment:

-

No.1-No1.5

-

Capacity:

-

1-20t/d

-

viscosity after treatment:

-

26.86-49.57(40C)mm2/s

-

Pour point after treatment:

-

-12 degree

-

Neutralization value:

-

0.02mgKOH/g

-

Open Flash point after treatment:

-

224Degree

-

limited vacuum:

-

50pa

-

recovery rate:

-

85%-90%

Quick Details

-

Marketing Type:

-

Hot Product

-

Flow:

-

2-10tons/day

-

Place of Origin:

-

Chongqing, China

-

Brand Name:

-

Tongrui

-

Voltage:

-

380V 50HZ 3P (Customizable), 380v/50hz/3phrase( or according to customers')

-

Power:

-

38-285KW

-

Dimension(L*W*H):

-

Model Choose

-

Weight:

-

7000 kg

-

Color after treatment:

-

No.1-No1.5

-

Capacity:

-

1-20t/d

-

viscosity after treatment:

-

26.86-49.57(40C)mm2/s

-

Pour point after treatment:

-

-12 degree

-

Neutralization value:

-

0.02mgKOH/g

-

Open Flash point after treatment:

-

224Degree

-

limited vacuum:

-

50pa

-

recovery rate:

-

85%-90%

Used Motor Oil to Diesel Oil Recycling Machine in South Africa

| The Feasibility of Engine Oil Refine to Diesel Fuel |

China`s engine oil production is approximately 20% of the total amount of the petroleum products, consumption is more than six million tons every year, most used for car engine, transmission, gear and turbine diver. The engine oil used by mechanical equipment,cars or ships, all the oil need to change and the change standard are definitely regulated(such as China: the oil must be changed every month). The oil will become ageing and metamorphism because the oxidation during the process of using, air will bring some water got to the oil, and the metal particles will be produced, the oil become to dirty, color become to black,which will decline the oil function,block the machines and pipes, so must change the oils.In terms of a middle-small cit, the production of waste engine oil of various cars, agricultural vehicle and other machineries is about 1000Ton, add the amount of waste oil from refining company, chemical factory, Fertilizer Plant and Coking factory, the total amount is prodigious.

Used engine oil, heavy fuel, bunker fuel,oil sludge,lubricant oil can be regenerated diesel oil,and the waste animal, vegetable oil, acid oil, drainage oil also can be convert to biodiesel oil. these available by-products can be converted as fuel oil directly,which is from the refinery, chemical plant, chemical fertilizer plant, urea plant, coking plant, such as: alcohols, sulfonated oil, naphtha, paraffin wax, benzene, naphthalene, ketones. If we deal these used oil and by-products by burning or burying, it is not only bring serious environmental pollution, also caused a huge waste of energy. So on the basis of reusing resources or environmental protection, or view the point of being able to bring enormous economic benefits for the producers, the waste oil for recycling has a very good prospects.

| The Main Feature |

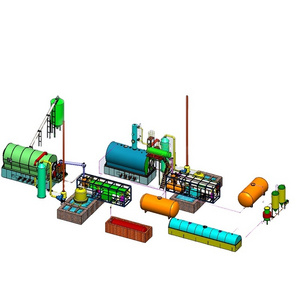

(1)Equipment composition

1)main components:spray gun,combustor/combustion chamber/burner,reactor,waste oil pump,gas manifold,sludge tank,condenser,oil tank,water seal/water block/hydroseal,induced draft fan/exhaust fan,dust removal chamber,chimney,electric control cabinet etc.

2) Combustor will provide heat energy for the entire process. Under the action of heat energy, the material will be cracked and generated a lot of oil vapor, which will be discharged into gas-oil separator and then passed into oil through condensers.Those incondensable gas will be filtered through water seal and last torched.what’s more ,we’ll handle the black smoke produced during processing in the dust removal chamber.

(2)

Features:

1)The entire process is absolutely environmental protection without any smoke and smell.

2) Decompression device is adopted water-circulation type to guarantee the security of the whole system.

3) The unit-time productive capacity as well as the quality of final oil will be rose drastically after decompression during the whole production process.

4) The heat system is adopted hot air heating technology,not only safety but also efficiency is increased in the production processing.

5)High-efficiency gas heating system.During the oil refining processing, there are some gases(methane--butane)produced when the temperature up to 150℃.Those gases will be burned in the special gas nozzle to produce a lot of energy and to save the resources.

6) The flue dust removal system with bidirectional spiral hydrodynamic impact on dust chamber can ensure that soot emission can be reached national standard for effluent discharge.

(3) Period warranty

100% brand new, we take one year(any of the damage caused by buyer shall not be the seller’s responsibility)quality guaranty.

|

Raw materials market Sources of raw materials (the waste oil from all kinds of auto repair shops, large-scale machinery, ships, agricultural vehicles , water pumps, tractors, transformers, as well as kinds of waste animal oil, vegetable oil, acidified oil, heavy oil, waste lube oil, alcohol sulfonated oil, naphtha, paraffin, benzene, naphthalene, ketone ) |

|

the main technical characteristics

1.The key parts of the equipment, cracking processor,which adopts a horizontal rotating structure. This structure have those advantages compared with the old ones. The fuel for new style fuel is fuel oil, and the residue generated during the fuel burning can be lived up to the world exhaust emission standards. Therefore, this fuel oil can be used in any country.

|

|

Applicable scope 1. waste plastics, crude oil generated from waste rubber...2. waste oil. For example: waste gasoline diesel oil, waste oil, waste engine oil, waste oil sludge, waste crude oil, waste oil used to wash spare parts, and so on. 3. various kinds of waste animal oil, vegetable oil, acidated oil, heavy oil, waste lube oil, alcohols, sulfonated oil, naphtha, paraffin, benzene, naphthalene, ketones). |

Technological process

Technological process: pump the waste oil into the negative pressure thermal cracking pyrolysis ffurnace, heat it and distillate into oil vapour, the oil vapour pass through the gas manifold,then go throught three-stage condenser to cool down the hot vapor to pethol and diesel oil;the waste gas will be collect and transport to the burner as fuel; and the residuel will be discharged automatically by sprial.

|

S ecurity |

During the process of oil refining, it will be dangerous if burn directly unliquified waste gases ,the major ingredients are sorts of alkane from C1 to C4. So before that, we’ll push it into the first safety device,water seal,then go into the second safety device,gas nozzle, to ensure it’s absolutely safe.

1.raw material of steels:5CrMoG15(steel plate for Chromium molybdenum boiler)

2. even if the equipment works under negative pressure, there are still triple insurances :

1)alarm for high temp, and cut off the diesel burner(in the electric controller )

2) alarm for over pressure

3) safe valve for over pressure

<

| Environmental Protection |

1. Exhaust

Through two safety devices,water seal and gas nozzle,not only eliminate air pollution but also save amount of fuel.

Soot emission can be reached the standard of Emission standard of air pollutants for coal-burning oil-burning

gas-fired boiler GB13271—2001.

the following is the text report in Singapore:

2. waste water

The water distilled from waste oil will be used as cooling water.

3. waste solids

There’s a little waste solids after catalytic craking,almost 5%-10% .its main component is crude carbon black.

it can be made as row material of producing industrial carbon black or fly ash brick(a kind of environmentally friendly

building materials) by mixing with coal ash produced by thermal power plant.

ZJB ZJB-T High Efficiency Vacuum Oil Purifier

ZJL Insulation Oil Multifunctional Oil Purifier

ZJR Multi-functional Double-Stage Vacuum Oil Regeneration Plant

ZJD lubrication Oil Specialized Purifier

ZJD-R Lubricating oil multi-function regeneration oil purifier

ZJD-S Special Off Water Oil Filter

ZJC Turbine oil vacuum purifier

BZ Decolor izing regeneration unit

YL/YL-B Series Portable Oil Filtration Machine

BK Press-filter purification plant

NRY series Black Engine Oil Regeneration System

Welcome to Scan My Two-Dimension Code Name Card, Let's Get Contact More Efficiently!

Any questions, don't hesitate to let us know it. Looking forward to build long friendly relationship with you!