- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

Henan Lanyu

-

Dimension(L*W*H):

-

15000*2100*5000mm

-

Weight:

-

25T

-

Certification:

-

CE

-

Product name:

-

Stone Crusher

-

The Machines classification:

-

Building Stone Production Line

-

Keyword:

-

Fine Stone Jaw Crusher

-

Installation:

-

Engineer Guide

-

Color:

-

Customizable

-

Spare parts supply:

-

12 Months Guarantee

-

Quality:

-

Advanced Technology

-

After sale Service:

-

Life-long Service

-

Material:

-

Q235

-

Name:

-

Crusher Stone Machine

Quick Details

-

Application:

-

sand making machine

-

Capacity(t/h):

-

10-100TH

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Henan Lanyu

-

Dimension(L*W*H):

-

15000*2100*5000mm

-

Weight:

-

25T

-

Certification:

-

CE

-

Product name:

-

Stone Crusher

-

The Machines classification:

-

Building Stone Production Line

-

Keyword:

-

Fine Stone Jaw Crusher

-

Installation:

-

Engineer Guide

-

Color:

-

Customizable

-

Spare parts supply:

-

12 Months Guarantee

-

Quality:

-

Advanced Technology

-

After sale Service:

-

Life-long Service

-

Material:

-

Q235

-

Name:

-

Crusher Stone Machine

lanyu sand making machinery/sand making plant/small gravel crusher

VSI sand making machine is a new type of sand making machine, which saves 50% energy compared with the traditional sand making machine. It can make all kinds of rocks, sand and river pebbles into construction sand with all kinds of granularity. The sand has uniform particle size and high compressive strength. The sand produced by natural sand and ordinary hammer sand beating machine is more in line with the building requirements and can improve the construction quality. The equipment has the characteristics of reliable performance, reasonable design, convenient operation and high working efficiency.

The application scope of VSI sand making machine is as follows:

1, river pebble, mountain stone (limestone, granite, basalt, diabase, andesite, etc.), ore tailings, artificial sand making of stone chips.

2. Production of building aggregate, highway pavement material, cushion material, asphalt concrete and cement concrete aggregate.

3. Water conservancy and hydropower, high-grade highway, high-speed railway, passenger dedicated line, bridge, airport runway, municipal engineering, high-rise building sand production and stone shaping.

4. Fine crushing technology, building materials, metallurgy, chemical industry, mine, refractory, cement, abrasive and other industries in the mining field.

5, high erosion and secondary disintegration and crushing, thermal power, metallurgical industry sulfur removal, steel slag, construction waste crushing and other environmental protection projects.

6. Production of glass, quartz sand and other high purity materials.

The application and advantages of VSI high efficiency sand making machine ae as follows:

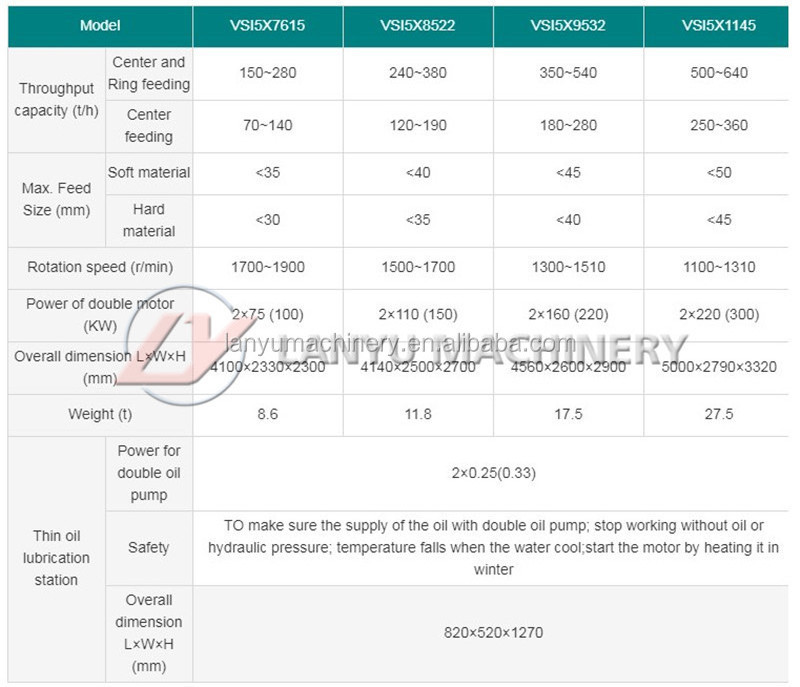

1, the processing capacity is large, the output is high: compared with the traditional equipment under the same power, the output is increased by 30% and the operation is stable;

2, the consumption of vulnerable parts is low: the impact angle of crushing cavity material is designed, the friction with wear-resistant parts is less, and the operating cost is 30% lower than that of traditional equipment, which directly reduces the cost of using the equipment.

3, the product grain shape is excellent: the product is cubic, the grain shape is good, the gradation is reasonable, the fineness modulus can be adjusted; especially suitable for artificial sand making and stone shaping, the practice proves that compared with other traditional equipment sand making, the shaping effect is 30% higher;

4, the hydraulic device is easy to maintain: the hydraulic opening cover device makes the maintenance and replacement of the parts in the broken cavity convenient and fast, shortens the downtime, saves time and labor;

5, automatic detection, safe and reliable: set up vibration display and alarm device, if the equipment has bad operation, can issue a warning, make the equipment stop working, achieve the purpose of protecting the machine;

6, dilute oil lubrication, automatic maintenance: Germany original dilute oil lubrication station, double oil pump complementary guarantee fuel supply, no oil flow, no oil pressure automatic stop; oil cooling and heating device to ensure that bearing lubrication is always in state. In order to completely solve the bearing heating and other problems, so that the spindle bearing to maintain constant temperature, prolong the maintenance cycle and service life;

7, the installation is simple, easy to operate: the equipment weight is light, the installation mode is diverse, the movable type installation; the installation, the repair and the maintenance is simple, the operation and use is convenient; once the specific use, the VSI sand making machine only needs to carry on the fine adjustment, can give full play to the performance;

8, one machine is multi-purpose and the application is flexible: the feed crushing structure has a variety of crushing cavity types, which can conveniently realize the conversion of "stone" and "stone iron", thus solving the problem of one machine and one machine. If we want to change the application of VSI sand making machine, we do not need to make big adjustment, which can not only meet the different needs of users: artificial sand making, gravel shaping, erosion material, etc.;

9, quality assurance: new technology, riveting technology application, appearance sandblasting rust removal treatment and painting process application of automobile technology, which greatly improve the internal quality and appearance quality of the equipment. The core parts are selected (bearings adopt high precision TIMKEN rolling bearings) to ensure the low failure rate of the system.

10, low noise, no pollution: air self-circulation system, greatly reducing external exhaust air volume, reducing dust, conducive to environmental protection. In addition, VSI sand making machine reserved and suitable for installation of a variety of specifications of dust removal equipment.

Packaging

:standard Container, Nude Packs or in Bulk.The electrical motor or spare parts will be packed by wooden case or steel frame.Lanyu offers various ways of package, fumigation-free wooden cases, steel plate cases, or as the clients' request. Most of the time, the equipment will be loaded to the containers in the factory. Lanyu workers make sure all equipment are steady and fixed before close the door of the container, there will be no damage during transporation and shipment.

Shipping

:we deliver the cargo to China's main sea ports,such as Qingdao,Tianjin,Shanghai etc.And then the container will be transported to your country by sea.