- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

KC

-

Dimensions(L*W*H):

-

1700*1250*1480 mm

-

Weight:

-

300 KG

-

Certification:

-

CE

-

Max. Print Area:

-

600*900mm

-

Machine name:

-

Motor Driving Silk Screen Press with Vacuum Table

-

Model:

-

S-JY6090PV

-

Keywords:

-

Silk Screen Press

-

Packing:

-

Wooden Pakage + film covering

-

date of delivery:

-

7days after payment

-

Color/station:

-

1 color 1 station

-

Item Name:

-

Motor Driving Silk Screen Printing Machine

-

Payment:

-

30%payment before Production

-

Operation:

-

Semi Auto Motor Driven

-

Application area:

-

Flat Objects

Quick Details

-

Condition:

-

New

-

Color & Page:

-

single color

-

Voltage:

-

110V/220V

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

KC

-

Dimensions(L*W*H):

-

1700*1250*1480 mm

-

Weight:

-

300 KG

-

Certification:

-

CE

-

Max. Print Area:

-

600*900mm

-

Machine name:

-

Motor Driving Silk Screen Press with Vacuum Table

-

Model:

-

S-JY6090PV

-

Keywords:

-

Silk Screen Press

-

Packing:

-

Wooden Pakage + film covering

-

date of delivery:

-

7days after payment

-

Color/station:

-

1 color 1 station

-

Item Name:

-

Motor Driving Silk Screen Printing Machine

-

Payment:

-

30%payment before Production

-

Operation:

-

Semi Auto Motor Driven

-

Application area:

-

Flat Objects

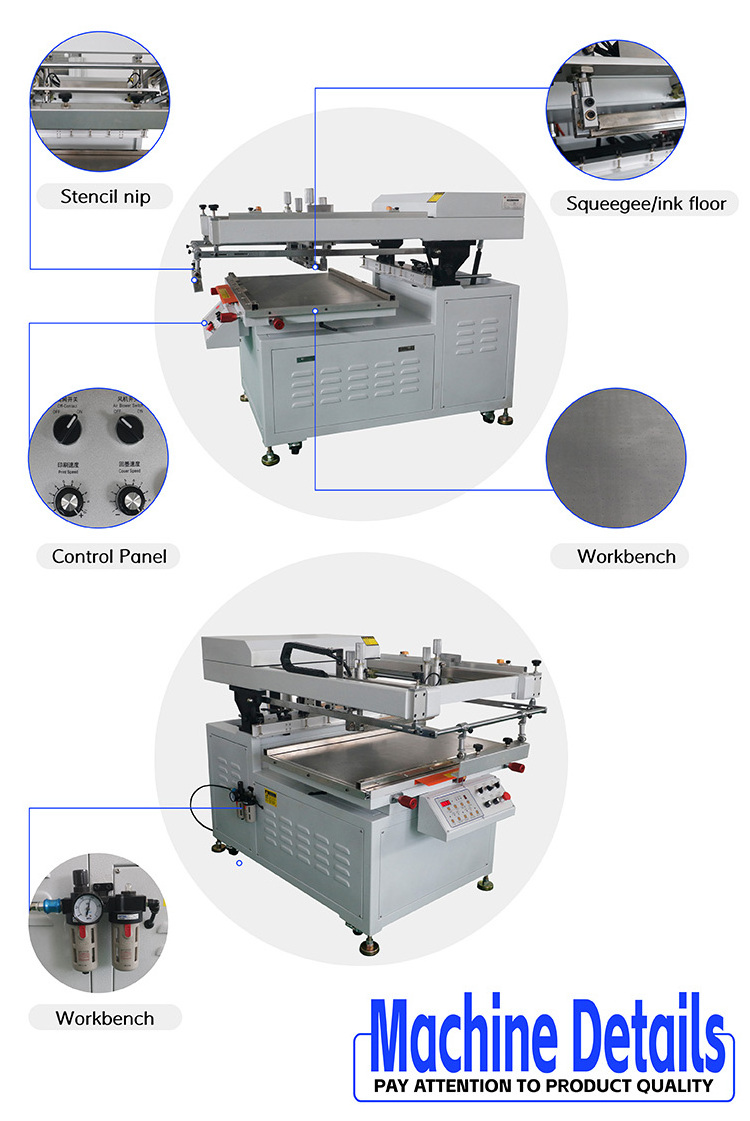

Motor Driving Silk Screen Press with Vacuum Table

The flat screen printing machine in which the screen is opened and closed at a certain angle and contacts the worktable is called an inclined arm screen printing machine. The screen clamping mechanism is installed on a cam rotating shaft, and the printing is completed by periodically leaving and contacting the worktable, and the printing speed is faster. , Compared with the screen printing machine with vertical lifting and lowering of the screen, the precision of the inclined arm type screen printing machine is lower. Another feature of the inclined arm type screen printing machine is that the scraper and the ink return knife move in the front and rear directions. The inclined arm type screen printing machine is especially suitable for occasions with large quantity, single product, and low precision requirements, such as: sublimation paper, partial UV, carton packaging, thermal transfer film, etc.

| Name | Mtor Driving Silk Screen Press with Vacuum Table |

| Model | S-JY6090PV |

| Max. printing area | 600*900mm |

| Working table size | 750*1000 mm |

| Max. printing thickness | 40mm |

| Max. printing speed | 1000Pcs/hr |

| Max. frame dimension | 900*1200mm |

|

Table adjustment Longitude |

±0.1mm |

|

Power Pressure |

4-6kgf/cm² |

| Voltage | 220v |

| Packing size | 1.8*1.32*1.45m |

| N.W/G.W | 420kg/460Kg |

1.Designed with its structure equipped with both power-driven and air-powered devices;

2.The printing operation and lifting transmission are under the control of the imported variable automatic system, and the complete machine is characterized by uniformity of operation;

3.Its printing plate is cast with aluminum alloy ,Stainless steel sheet of 2mm in thickness is adhered to the surface of the printing plate, and the printing plate may be smooth, even, and free from distortion;

4.It is provided with coordinate vernier device and automatic air-intake function, ensuring still more easy and accurate printing plate alignment;

5.Slide rail adopts linear guide rail made in Germany, Free of attrition wear. Transmission gear is equipped with imported timing belt and it is characterized by free actuation and adjustable speed;

6.Pressure of squeegee blade and in returning blade are adjustable and may be separately manipulated, and adjustment up to 45 degrees is allowed as well;

7.It is equipped with safe bounce-back function, ensuring safety in operation it is also provided with automatic synchronous screen-departure function , and this may avoid the scumming of printed materials effectively;

8.All components of the electrical section are from noted brands, its panel is fitted with electronic touch keys. the complete machine is coated with static pyrolytic coating, with esthetic appearance , good taste, and solvent resistance.

1. Fit printing soft and thin products such as paper, plastics film etc.;

2.With vacuum working table ensure adsorbing object when printing;

3.Working table keep stillness but screen frame moving along slant angle make the printing speed higher ;

4.Also widely used in Glass Plate, Machine panel screen printing;

5.With UV curing machine, Can finish many UV special printing process including UV Spot Varnish, UV frosting , UV glitter Powder ;

6.Suitable for printing sheet-fed adhesive sticker;

7.Suitable for printing water transfer label and heat transfer label through different process;

8.Rubber Squeegee movement driven by Taiwan frequency conversion controlling system ;

9.Widely used to print circuit aboard , Film switch panel etc. industrial High technology field.