- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

HengYuan

-

Voltage:

-

380V, customized

-

Power:

-

850

-

Dimension(L*W*H):

-

80m*6m*1.8m

-

Weight:

-

110000 kg

-

Production Name:

-

Iron Cold ERW Pipe Mill Production Line

-

Raw Materails:

-

Carbon Steel, Low Alloy, High Strength Steel and ect

-

Final Pipe Shape:

-

Round, Square, Rectangular and ect

-

Max Steel Thickness:

-

12mm

-

Pipe Length:

-

4-8m

-

Steel Coil OD.:

-

800-1500mm

-

Steel Coil ID.:

-

450-550mm

-

Welding Type:

-

High Frequrency

-

Max Loading Weight:

-

≤6000kg

-

Color:

-

Customized

Quick Details

-

Pipe Material:

-

Carbon steel

-

Production Capacity:

-

15-100m/min

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

HengYuan

-

Voltage:

-

380V, customized

-

Power:

-

850

-

Dimension(L*W*H):

-

80m*6m*1.8m

-

Weight:

-

110000 kg

-

Production Name:

-

Iron Cold ERW Pipe Mill Production Line

-

Raw Materails:

-

Carbon Steel, Low Alloy, High Strength Steel and ect

-

Final Pipe Shape:

-

Round, Square, Rectangular and ect

-

Max Steel Thickness:

-

12mm

-

Pipe Length:

-

4-8m

-

Steel Coil OD.:

-

800-1500mm

-

Steel Coil ID.:

-

450-550mm

-

Welding Type:

-

High Frequrency

-

Max Loading Weight:

-

≤6000kg

-

Color:

-

Customized

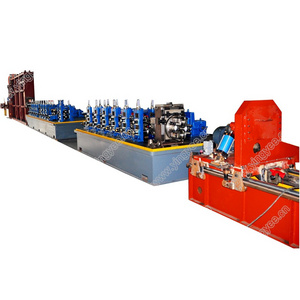

High Output Iron Cold ERW Pipe Mill Production Line for Straight Seam Carbon Steel Pipes

1.Brief Introduction of Iron Cold ERW Pipe Mill Production Line

This euqipment is specially used for producing high-frequency straight seam welded pipe and corresponding square pipe and special-shaped pipe. The composition of equipment is from uncoiler to fixed length cutting saw. Rolling speed can be adjusted correspondingly within suitable range of pipe diameter and wall thickness.

2.Technology Parameter for Iron Cold ERW Pipe Mill Production Line

|

Diameter of Welded Tube |

Wall Thickness of Welded Tube |

Speed of Tube Welding |

Power |

High Frequency Power |

|

|

HY16 |

8-25mm |

0.25-1.0mm |

30-100m/min |

30kw |

60kw |

|

8-32mm |

0.35-1.3mm |

30-100m/min |

45kw |

100kw |

|

|

HY32 |

13-50.8mm |

0.5-2.0mm |

30-90m/min |

110kw |

150kw |

|

HY50 |

20-63.5mm |

0.6-2.5mm |

30-90m/min |

160kw |

200kw |

|

HY60 |

25-63.5mm |

0.8-3.0mm |

20-80m/min |

185kw |

250kw |

|

HY76 |

25-80mm |

1.2-4.0mm |

20-70m/min |

200kw |

300kw |

|

HY90 |

32-90mm |

1.5-4.5mm |

20-60m/min |

110*2kw |

400kw |

|

HY115 |

38-115mm |

2.0-5.0mm |

20-60m/min |

160*2kw |

400kw |

|

HY165 |

80-165mm |

2.0-6.0mm |

15-50m/min |

200*2kw |

500kw |

|

HY219 |

90-219mm |

3.0-8.0mm |

15-50m/min |

250*2kw |

600kw |

|

HY273 |

185-273mm |

4.0-10.0mm |

15-40m/min |

250+185kw |

800kw |

|

HY300 |

165-355mm |

4.0-12.0mm |

15-30m/min |

250+200kw |

1200kw |

3.

T

echnological Process for Iron Cold ERW Pipe Mill Production Line

Strip coil

→

Uncoiler

→

Shear and butt-welder

→

Accumulator

→

Levelling

→

Forming

→

Welding

→

External burr removing

→

Cooling

→

Sizing

→

Straightening

→

Cut size

→

Packing

4.Moulds and Rollers for Iron Cold ERW Pipe Mill Production Line

A series of supporting roll mould of HG12, 25, 32, 50, 60, 76, 90, 115, 165, 219 welded pipe units as well as the stainless units cold-bending forming units.

Our factory roller or moulds is adopted a complete set of advanced machining craft process, no matter the material forging, heat treatment, or mechanical rough machining and finish machining, we also can make the surface nitrogen treatment according to the users’ demands, so as to guarantee the mould has the high precision, good quality and long service life.

5.

Shear Welder for Iron Cold ERW Pipe Mill Production Line

The shearing and welding machine is used to cut off the irregular parts of two strip coils’ head and end, then take alignment welding. It takes pneumatic (or hydraulic) cutting and semi-automatic TIG welding.

6.Accumulator for Iron Cold ERW Pipe Mill Production Line

Material accumulator is used to store a certain amount of strip steel to provide main machine, it can ensure the continuous production requirement of main machine during the strip connection period.

7.Cutting-Saw for Iron Cold ERW Pipe Mill Production Line

(1)Cold cutting-saw

It is used to carry out the online fixed-scale cutting for the welded steel pipes. It can make the high speed rotation by the discal saw blades, and the computer program control to reach to the purpose of cutting tracking and accurate positioning.

(2)Computer cutting-saw

It is used to carry out the online fixed-scale cutting for the welded steel pipes. It can make the high speed rotation by the discal saw blades, and the computer program control to reach to the purpose of cutting tracking and accurate positioning.

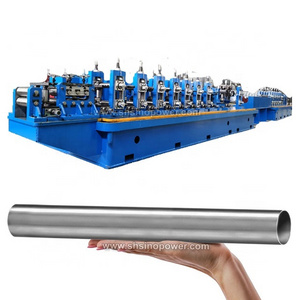

8.Final Pipe Products for Iron Cold ERW Pipe Mill Production Line

9.Our Workshop for Iron Cold ERW Pipe Mill Production Line

10.About Our Company

According to our factory idea, science and technology can create the continuous increasing ultimate valve to the customers, “creating the valve for the clients” is the core, constantly innovates the products and improves the service quality to realize the maximum valve for the customers. Our factory only makes the customers’ reliable brand, and gets the approbation form the clients, which is the significance.

After decades of development, our factory has attained a pleasant performance on the manufacturing, research and development of welded pipe units, slitting machines, rolling mill series of equipment.

If you are interested in this

iron cold ERW pipe mill production line

, welcome to contact with me freely as the followings: