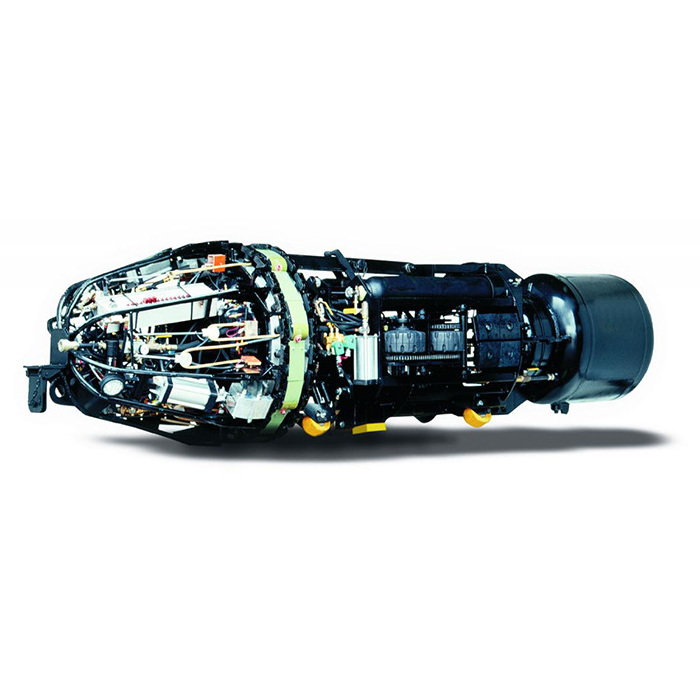

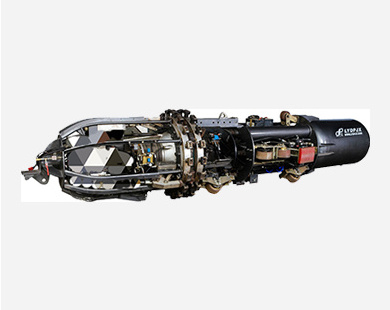

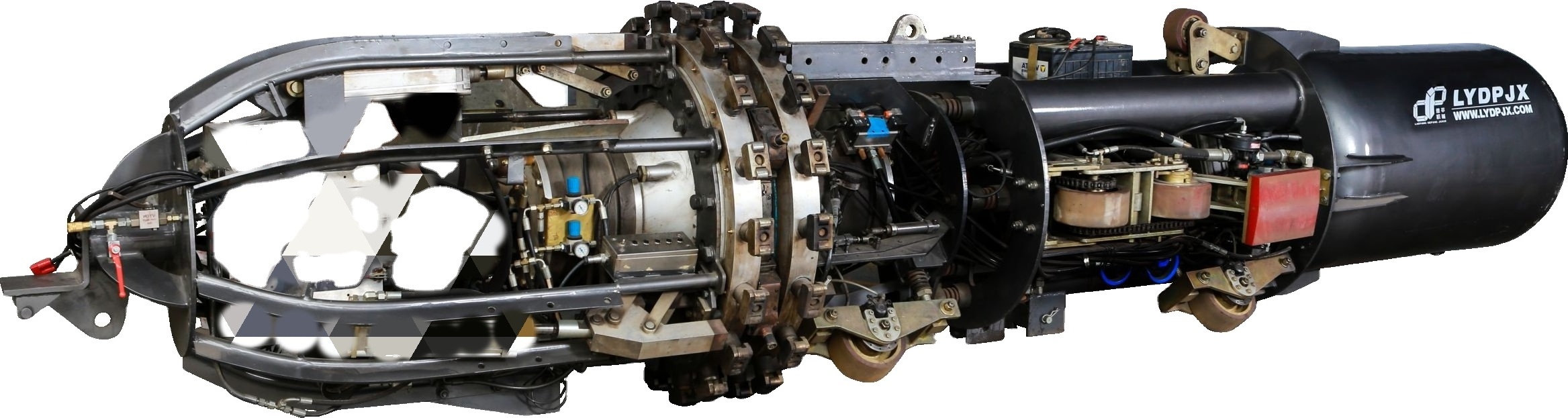

1. DPIWM series automatic welding machine is a complete automatic welding system, it combines pipe line up work and root pass

welding, hot pass welding, gap pass welding together, a totally efficienty way to reduce time.

2. Adopts GMAW constant-voltage welding, heavy duty power source, can be used both onshore and offshore.

3. Automatic welding machine must be a new trend because of high accuracy and efficient requirement

4. DPIWM SERIES Internal welding machine can cover pipe size from

24in to 62in

5. Internal welding machine with two control panels: close and remote control

Advantages as below

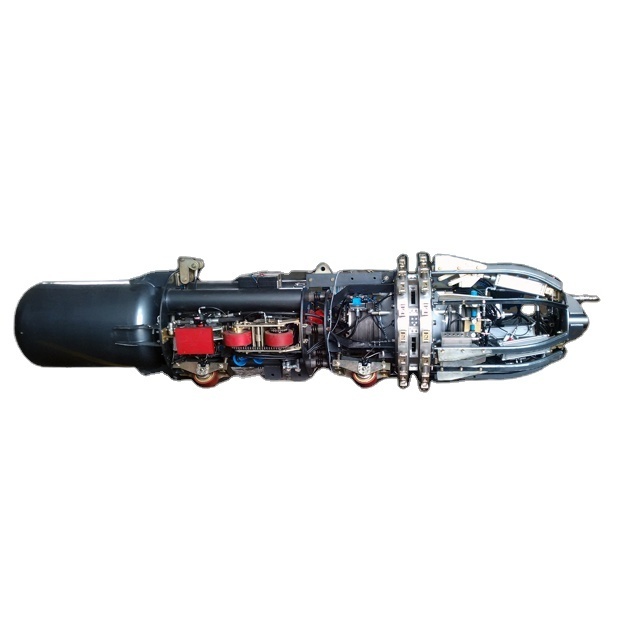

1. High reliability: it is double sides double wheels driving mode, travelling part adopts both pneumatic and electric systems,

with real-time feedback of wire feeding speed, speed auto-change of slight variation also has powerful supporting ability and

Pipe roundness correction.In order to improve welding quality, efficiency, and material performance, DPIWM adopts GMAW, which can be used both onshore and offshore. Different wall thickness could be achieved with adjustment of the welding torch.

2. High welding efficiency: the applicable range is from 24 inch to 62 inch. It has 2-10 welding torches in 360°direction. With close and remote control box, it can achieve maximum welding time and reduce labor intensity.

3.

Max. line up supporting ability

4.

Perfect welding seam of automatic welding machine