- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

All Model

-

Product name:

-

Rubber Bladder

-

Material:

-

Rubber

-

Color:

-

Black

-

Pressure Level:

-

1.6MPa≤p<10.0MPa

-

HS Code:

-

8481100090

-

Advantage:

-

Long Working Life

-

Application:

-

Hydraulic Accumulator Bladder

-

Dimension:

-

Various sizes

-

MOQ:

-

1 Piece

-

Sample:

-

Availabe

Quick Details

-

Processing Service:

-

Blow Molding

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Lake Petro

-

Model Number:

-

All Model

-

Product name:

-

Rubber Bladder

-

Material:

-

Rubber

-

Color:

-

Black

-

Pressure Level:

-

1.6MPa≤p<10.0MPa

-

HS Code:

-

8481100090

-

Advantage:

-

Long Working Life

-

Application:

-

Hydraulic Accumulator Bladder

-

Dimension:

-

Various sizes

-

MOQ:

-

1 Piece

-

Sample:

-

Availabe

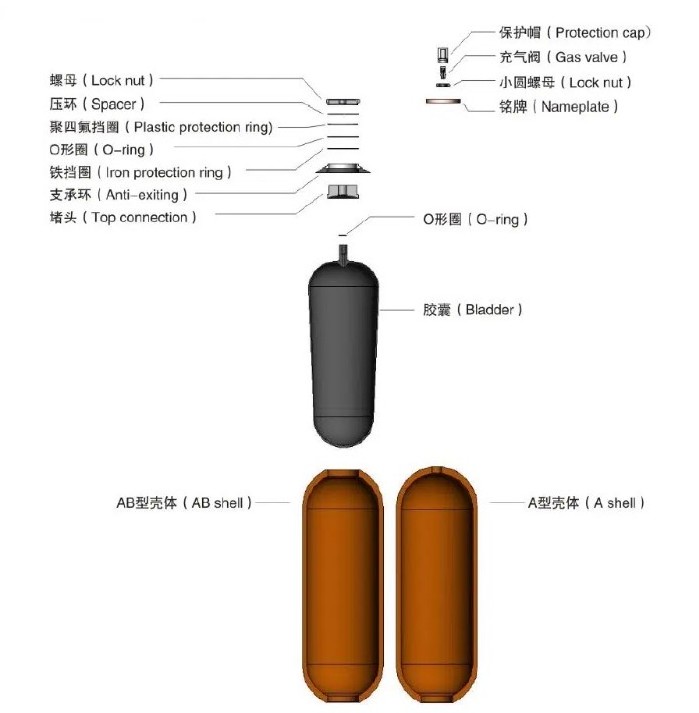

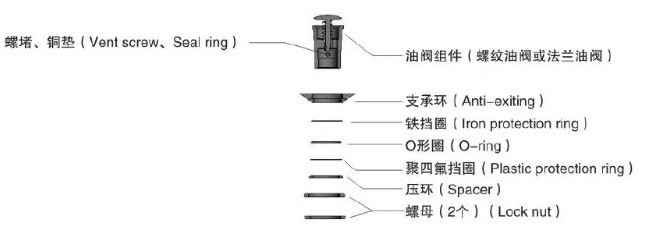

Accumulators use incompressi bl e fluid and a compressed gas, spring or raised mass to store potential energy. Accumulators are used in fluid power systems to store energy , absorb shock, and maintain system pressure. The compressi b ility of gas ( nitrogen) is utilized in hydro-pneumatic accumulator for storing fluids. INNOVAT bl adder accumulators are based on this principle, using nitrogen as the compress ibl e medium. The bl adder accumulator consists of a fluid section and a gas section with the bl adder action as a gas-proof screen. The fluid around bl adder is connected with the hydraulic circuit, so that the bl adder accumulator draws in fluid when pressure increases and the gas is compressed. When the pressure drops, the compressed gas expands and forces the stored f luid into the circuit .

| No | Selection: | ||

| 1 | Fluid power storage. | ||

| 2 | Pulsation damper. | ||

| 3 | Absorb the emergency energy. | ||

| 4 | Thermal expansion compensation . | ||

Special

A

pplication

A

ccumulator

Low

temperature

impact

test

is

required

to accumulator shell and metal parts.

Low temperature nitrile ( N BR ) is required.

AII latex parts (

O

ring,

anti-extrusion ring) must

be

low temperature materials .

High temperature nitrile is required

All paerts must be high temperature materials.

Shell electroless nickel plating phosphorus alloys.

Butyl rubber is required.

AII rubber seal choose butyl rubber.

Oil valve and contact with th

e

media parts choose stainless steel materia

l

We designed and manufactured high performance with a flow rate of up to 20L- 30 L.

The fluid connection is enlarged to allow higher flow rates.

lt can meet with the requirements of some s pecial hydraulic equipment.