and no sag edge

- Product Details

- {{item.text}}

Quick Details

-

Feature:

-

COMMON

-

Keyword:

-

Laminated Gypsum Boards

-

Coreboard:

-

Standard Paper-faced Gypsum Board

-

Moisture content:

-

≤2%

-

Edge:

-

Square, Wrapped

-

Function:

-

Decorative, Explosion-proof, Heat Insulation

-

Surface Treatment:

-

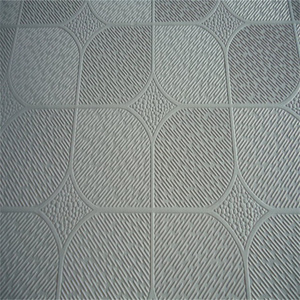

Embossed, Frosted / Etched, Opaque

-

Color:

-

white gold and colored

-

Size:

-

595*595mm 603*603mm 600*600mm

-

Thickness:

-

7-12mm

-

Usage:

-

Interior Wall Ceiling Decoration

Quick Details

-

After-sale Service:

-

Online technical support, Onsite Installation, Onsite Training, Onsite Inspection, Free spare parts, Return and Replacement

-

Project Solution Capability:

-

graphic design, 3D model design, total solution for projects

-

Application:

-

School

-

Feature:

-

COMMON

-

Keyword:

-

Laminated Gypsum Boards

-

Coreboard:

-

Standard Paper-faced Gypsum Board

-

Moisture content:

-

≤2%

-

Edge:

-

Square, Wrapped

-

Function:

-

Decorative, Explosion-proof, Heat Insulation

-

Surface Treatment:

-

Embossed, Frosted / Etched, Opaque

-

Color:

-

white gold and colored

-

Size:

-

595*595mm 603*603mm 600*600mm

-

Thickness:

-

7-12mm

-

Usage:

-

Interior Wall Ceiling Decoration

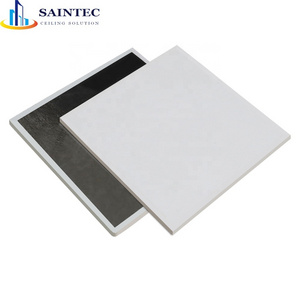

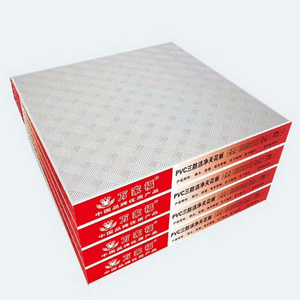

Pvc Film High Quality Pvc Paper Laminated Gypsum Boards False Ceiling Tiles For Decoration

Specification

|

Material

|

Topside is pvc film,backside is aluminum foil,coreboard is paper faced gypsum board, four edge coverd by tapes

|

|

Thickness

|

7mm,7.5mm,8mm,8.5mm,9mm,9.5mm,12mm,12.5mm

|

|

Popular size

|

595x595mm,603x603mm(2'x2')

|

|

Weight per piece(2'x2')

|

7mm:2kg/pc;

7.5mm:2.15kg/pc;

8mm:2.3kgs/pc;

9mm:2.5kg/pc;

12mm:3.3kg/pc

|

|

Moisture content

|

<1%

|

|

Strength

|

>160N

|

|

Noise reduction coefficent

|

0.3-0.5

|

|

Thermal conductivity

|

resistant to 95% hunmidity and water

|

|

Light reflectance

|

0.75

|

|

Sagging resistance prospertity

|

warranty against visible sagging

|

Product Description

Product description:

PVC veneer gypsum board, refers to the use of PVC as the main material side of the gypsum board, the use of screen printing technology will be graphics, text, logo set in one of the main role of protection and labeling of a film, the other side is posted A foil aluminum foil to ceiling as the main material of gypsum board.

PVC veneer gypsum board, refers to the use of PVC as the main material side of the gypsum board, the use of screen printing technology will be graphics, text, logo set in one of the main role of protection and labeling of a film, the other side is posted A foil aluminum foil to ceiling as the main material of gypsum board.

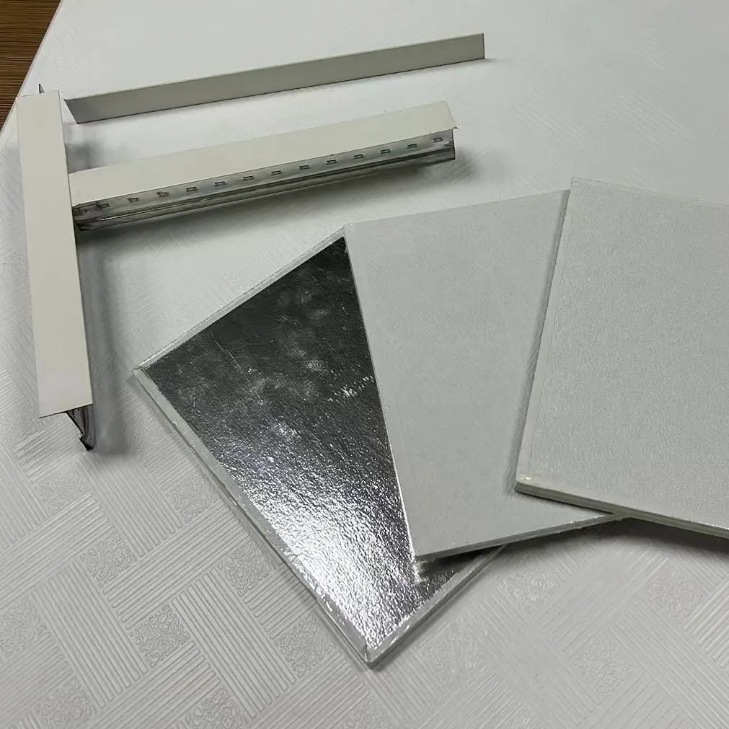

Front

Back

Edge

Waterproof PVC, smoothly Fireproof aluminum foil, smooth

Tape is wrapped tightly on

Details Images

Features

Safe, environmental, healthy, non-dust, noxious-free, moisture-proof, sunken proof, and easy clean. It is an economical, elegant,fashionable decorative ceiling tiles.

Safe, environmental, healthy, non-dust, noxious-free, moisture-proof, sunken proof, and easy clean. It is an economical, elegant,fashionable decorative ceiling tiles.

Application

Indoor decoration of super class buildings such as hotels, restaurants, shopping malls theaters, cinemas, stations, auditoriums, offices, sitting rooms, business buildings, electronic workshops, precision apparatus rooms and industrial or residential buildings.

Indoor decoration of super class buildings such as hotels, restaurants, shopping malls theaters, cinemas, stations, auditoriums, offices, sitting rooms, business buildings, electronic workshops, precision apparatus rooms and industrial or residential buildings.

Product Catalog

Our company have more than 150 designs, including white and colorful, if you want to know other designs, feel free to contact us any time!

Installations

Required accessories

1.PVC Laminated Gypsum Ceiling Tile

2.Explosive Bolt

3.Hanger

4.Connector

5.Wall Angel

6.Load Channel

7.Cross Tee

8.D-T Connector

9.Main Tee

STEPS

1.Determine the ceiling elevation horizontal line, pop up the peripheral line, and install the edge keel.

2.

Pop up the vertical cross bisector line, and determine the two middle lines, draw the distance according to the ceiling specifications, and find the location of the boom.

3.

Install expansion bolts according to the position of the suspension rod and hang the suspension rod.

4.

Taking into account the installation positions and methods of light panels, exhaust vents, fire hydrants, etc.

5.

The suspension rod is installed on the main keel and adjusted to be close to horizontal.

6.

Insert the secondary keel into the required size space.

7.

Overall level adjustment and elimination of visual errors.

8.

Install the ceiling, the four edges are not whole panels, cut according to size. To determine the direction of the main keel.

Packing & Delivery

|

Thickness

|

KGS/PCS

|

PCS/CTN

|

KGS/CTN

|

M2/20GP

|

CTNS/20GP

|

PCS/20GP

|

TONS/20GP

|

|

7.0

|

2.08

|

8

|

16.60

|

4150

|

1422

|

11000

|

22.88

|

|

8.0

|

2.22

|

8

|

17.80

|

3850

|

1337

|

10696

|

23.80

|

|

8.5

|

2.30

|

8

|

18.40

|

3600

|

1250

|

10000

|

23.00

|

|

9.0

|

2.48

|

8

|

19.84

|

3200

|

1111

|

8888

|

22.04

|

|

12.0

|

3.26

|

8

|

19.60

|

2274

|

1053

|

6496

|

20.60

|

Related Product

Hot Searches