- Product Details

- {{item.text}}

Quick Details

-

Dimension(L*W*H):

-

6000*2600*2600

-

Power (kW):

-

17 kW

-

Weight (KG):

-

29000 KG

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Product name:

-

High yield used car tires recycling machine factory

-

Raw material:

-

Waste Tyre

-

Application:

-

Recycle Waste Tires

-

Function:

-

Make Oil

-

End product:

-

Fuel Oil Steel Carbon Back

-

Color:

-

Demands

-

Machine Type:

-

Semi-automatically

-

Fuel material:

-

Coal,wood,gas,oil

-

Usage:

-

Used Tire Recyling

-

Certification:

-

CE,ISO,BV,TUV

Quick Details

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Lanning

-

Voltage:

-

380V

-

Dimension(L*W*H):

-

6000*2600*2600

-

Power (kW):

-

17 kW

-

Weight (KG):

-

29000 KG

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Product name:

-

High yield used car tires recycling machine factory

-

Raw material:

-

Waste Tyre

-

Application:

-

Recycle Waste Tires

-

Function:

-

Make Oil

-

End product:

-

Fuel Oil Steel Carbon Back

-

Color:

-

Demands

-

Machine Type:

-

Semi-automatically

-

Fuel material:

-

Coal,wood,gas,oil

-

Usage:

-

Used Tire Recyling

-

Certification:

-

CE,ISO,BV,TUV

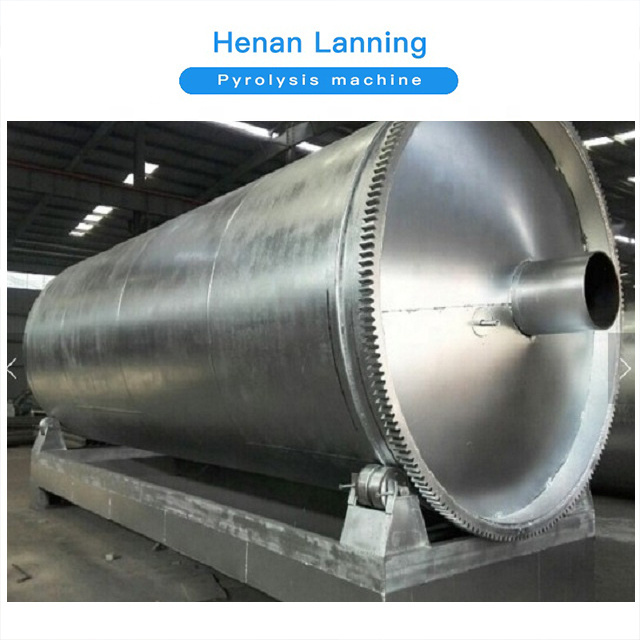

High yield used car tires recycling machine factory

1. The Raw Material For Pyrolysis Machine

|

NO. |

Raw material |

Note |

|

1 |

Waste tyre |

Steel tyre ,Nylon tyre ,Bick tyre |

|

2 |

Waste plastic |

PE,PVC,Waste washed mixture plastic from waste Paper Factory |

|

3 |

Waste rubber |

Shoes Soles,Cable Skin |

|

4 |

oil sludge,waste oil sludge |

|

|

We have our own lab to test the oil output rate of your raw material ,welcome you contact |

||

2. Pyrolysis plant models and specification

|

Product Model |

Specifications |

Per batch capacity |

Per day output |

Containers |

Gross weight |

Power |

|

LN-2200*6000 |

2200mm*6000mm |

6ton |

3ton |

2*40HQ |

25ton |

12kw |

|

LN-2200*6600 |

2200mm*6600mm |

7ton |

4ton |

2*40HQ |

27ton |

12kw |

|

LN-2600*6000 |

2600mm*6000mm |

8ton |

5ton |

1*40HQ&1*FR |

30ton |

16kw |

|

LN-2600*6600 |

2600mm*6600mm |

10ton |

6ton |

1*40HQ&1*FR |

33ton |

17kw |

|

LN-2800*6000 |

2800mm*6000mm |

10ton |

6ton |

1*40HQ&1*FR |

36ton |

17kw |

|

LN-2800*6600 |

2800mm*6600mm |

12ton |

7ton |

1*40HQ&1*FR |

39ton |

17kw |

3.The available fuel for pyrolysis processing

|

NO. |

Fuel |

|

1 |

Oil(fuel oil, tyre oil, heavy oil etc..) |

|

2 |

Natural gas |

|

3 |

Coal |

|

4 |

Firewood |

|

5 |

Carbon black pellet |

4. End product percentage and useage( Example : raw material is tyre)

|

NO. |

Name |

Percentage |

Usage |

|

1 |

Tyre oil |

45% |

* can be sold directly. * make diesel and gasoline by use oil distillation machine. * can be as fuel. |

|

2 |

Carbon black |

30% |

* can be sold directly. * make fine carbon by use carbon black refining machine. * make pellet by use carbon make pellet machine. |

|

3 |

Steel wire |

15% |

* can be sold directly. * make steel bloom by use hydraulic press-packing |

|

4 |

Oil gas |

10% |

* can be as fuel burn by use gas burn system (pyrolysis machine included) *extra gas also be storage as fuel for other heating. |

5. Pyrolysis machine advantage and main technical characteristics

1. High oil output rate 45%--55% with special catalyst formula and high tech .

2. Rapid condensers and large cooling area,assure you get much more and higher quality oil.

diversiform cooling system can be choose according to client's willingness

3. Dust-removing device -four levels dust processing system make sure no any population and the

output smoking is the spray .more environmental protection.

4. Double tail-gas recycling and burning system, saving energy.

5. Q245R boiler plate, high temperature resistance, thickness reaches 14mm—16mm,guarantee

4-7 years service lives. and optional plate is Q345R

6. OptionalAuto feeder and carbon black discharge elevator, high automation, saving time and labors.

7. Eco-friendly and no any population, environmental protection

6.Machine 3D drawing flow chart and working processing

The machine can delivery within 15 working days after receiving deposit