- Product Details

- {{item.text}}

Quick Details

-

Screw Speed (rpm):

-

1200 rpm

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

TongSan

-

Voltage:

-

380V 50HZ 3Phase(Customized)

-

Dimension(L*W*H):

-

20m2*.5m*2.2m

-

Power (kW):

-

37

-

Weight:

-

2 KG

-

Name:

-

Extrusion Machine

-

Raw material:

-

PVC Powder,wood powder

-

Inverter:

-

ABB Brand

-

Motor brand:

-

SIENEMS

-

Power:

-

AC380V,50HZ

-

Sheet Width:

-

1220mm

-

thickness:

-

3-35mm

-

Capacity:

-

300-400kg/h

-

Product:

-

Sheet Production

-

Color:

-

Customer Choice

Quick Details

-

Screw Design:

-

Double-screw

-

Screw L/D Ratio:

-

1:28

-

Screw diameter (mm):

-

210 mm

-

Screw Speed (rpm):

-

1200 rpm

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

TongSan

-

Voltage:

-

380V 50HZ 3Phase(Customized)

-

Dimension(L*W*H):

-

20m2*.5m*2.2m

-

Power (kW):

-

37

-

Weight:

-

2 KG

-

Name:

-

Extrusion Machine

-

Raw material:

-

PVC Powder,wood powder

-

Inverter:

-

ABB Brand

-

Motor brand:

-

SIENEMS

-

Power:

-

AC380V,50HZ

-

Sheet Width:

-

1220mm

-

thickness:

-

3-35mm

-

Capacity:

-

300-400kg/h

-

Product:

-

Sheet Production

-

Color:

-

Customer Choice

Product Description

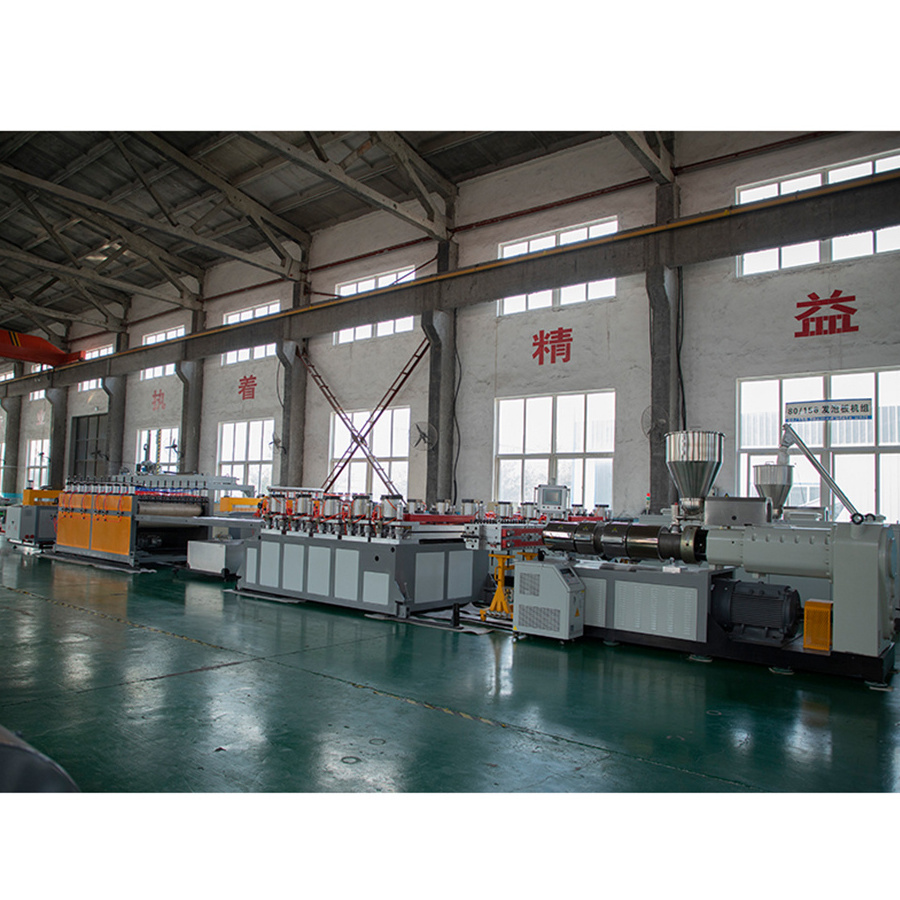

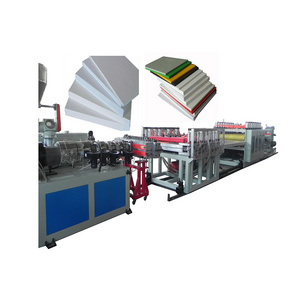

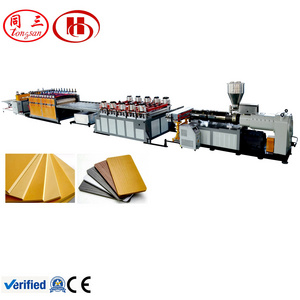

900-1220mm with PVC WPC solid foamed furniture board and solid door board making machine with CE certificate

WPC solid door board making machine for 30-45mm thickness e is used for making 30-45mm solid WPC foam board for door panel, it uses PVC and wood fiber as raw material, by semi-crust or full-crust foaming technology, to make WPC solid boards/panels with low density for 0.45-0.8gram/cm3, the WPC foam boards are widely used for making furniture panel, construction formwork, partition wall....

|

Model

|

SJMS80/173

|

|

Product width

|

1220mm

|

|

Product thickness

|

5-45mm

|

|

Capacity

|

350-450kg/h

|

|

Raw material

|

PVC and wood powder

|

|

Motor power

|

90kw

|

|

Inverter

|

ABB brand

|

|

Gearbox

|

Guomao

|

|

Screw material

|

38CrMoAIA+ Bimetallic

|

Detailed Images

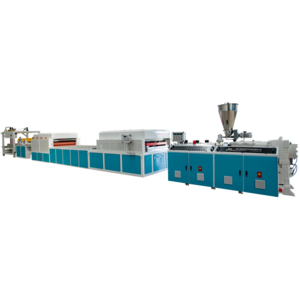

PVC/WPC board machine can continuously produce PVC WPC foam board.This production line is composed of extruder, mould, calibrating platform, cooling frame, haul off machine, cutting machine and stacker.

The customer can also produce A+B+A three layers co-extrusion foam board by adding extruder and distributor .The machine should equip with water chiller, can increase production efficiency.

The customer can also produce A+B+A three layers co-extrusion foam board by adding extruder and distributor .The machine should equip with water chiller, can increase production efficiency.

Auto feeder

Automatic feeding device made by stainless steel, adopting spiral screw feeding, with double screw feeding hopper.

Extruder

Conical double screw extruder with special designed Screw and Barrel, the screw and barrel must be designed for high foaming

technology with one foaming zone

technology with one foaming zone

Electric control system

ABB inverter

Omron temperature control

Siemens PLC control

Siemens contractor

Siemens motor

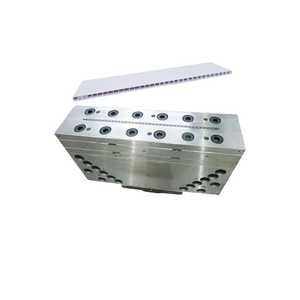

Die head

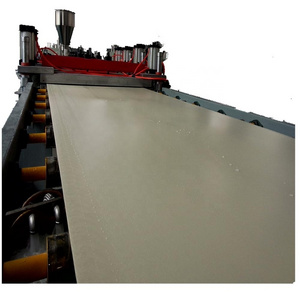

WPC foam board die head is made by special high quality mold material with good resistance for WPC material, the die head width is 1450mm which can make 1220mm width product

Calibrator

adopting water cooling inside the calibrators, the products shall be cooled by the calibrators without touching water, the calibrators are designed for celluca foaming technology to make inner foamed and skinned surface WPC foam board

Cooling bracket stacker

WPC foam board cooling bracket is designed for air natural cooling after calibrating, it can make the WPC foam board with uniform

surface without bending, 5 meters cooling bracket is necessary

surface without bending, 5 meters cooling bracket is necessary

Haul off machine

WPC foam board haul off machine is designed with strong haul off force, it is necessary to use 8 pairs or 10 pairs of high quality

rubber rollers which is drived by gear connection

rubber rollers which is drived by gear connection

Edge cutting machine

WPC foam board edge cutting machine is used for cutting the edges of WPC foam board to ensure the uniform cutting edge, the cutting waste can be recycled and reused

Length cutting machine

WPC foam board length cutting machine is used for cutting the length of WPC foam board, it adopts automatic cutting with length metering device.

Our service

Company profile

Certifications

Customer Photos

FAQ

Hot Searches