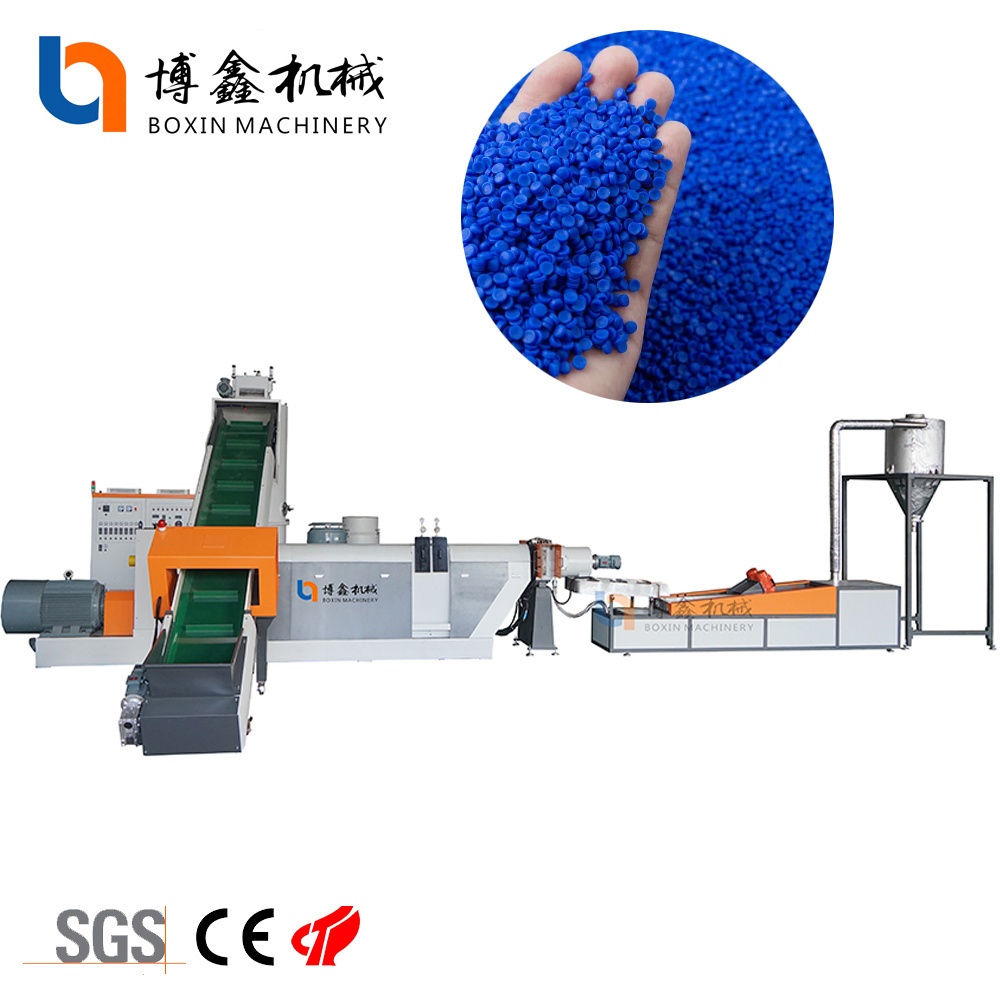

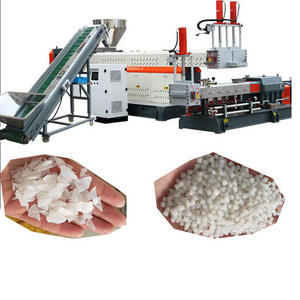

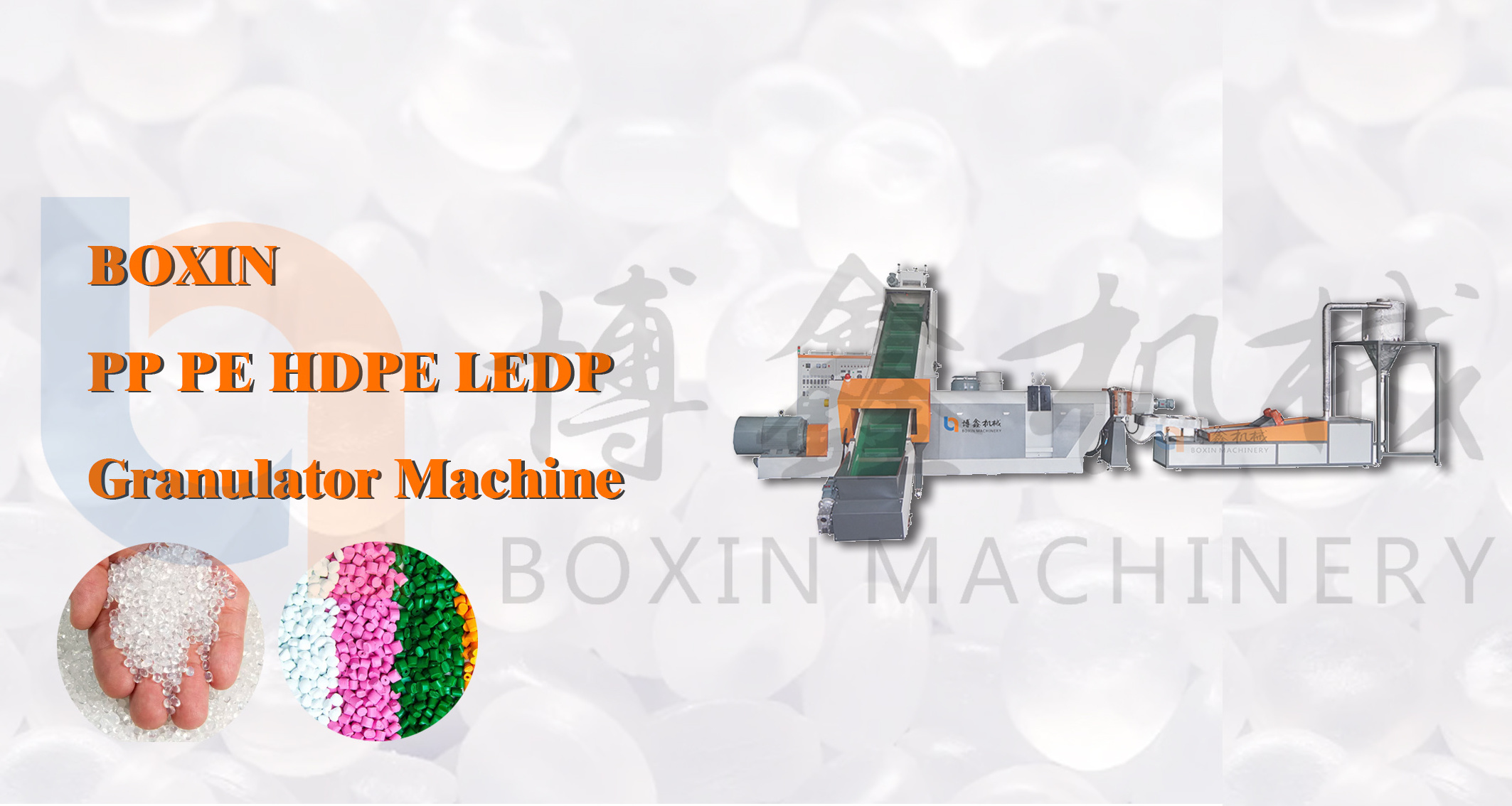

Boxin have two types of PP PE pelletizer machine/granulator : one stage and two stags. mother baby Plastic pellet making machine is especially good for the raw material which contain high moisture, high impurities.

The first stage extruder adopts exhaust type barrel screw, which can effectively de-gassing and eliminate the moisture and

contamination; And the second extruder usually adopts small L/D extruder, further plasticizing the material and filter

contamination which can achieve stable extrusion.

- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

BOXIN

-

Application:

-

PP PE film,bags,woven

-

Production Capacity (kg/h):

-

1000 - 5000

-

Voltage:

-

380V/50HZ

-

Dimension(L*W*H):

-

65*6*5M

-

Power (kW):

-

210-260

-

Weight (T):

-

5

-

Name:

-

Plastic Granule Machines

-

Final product:

-

Granulating Production Line

-

Keywords:

-

Film Pelletizing Line

-

Raw material:

-

PP PE Film Bags Material

-

Capacity:

-

500-5000kg/h

-

Usage:

-

Granules Making Machine

-

Function:

-

Recycling Granulator

-

Hot search:

-

recycle plastic granules

-

Type:

-

Recycling Granulator

-

After Warranty Service:

-

Field maintenance and repair service

Quick Details

-

Machine Type:

-

PP PE Film Washing Line

-

Max.Production Capacity (kg/h):

-

5000

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

BOXIN

-

Application:

-

PP PE film,bags,woven

-

Production Capacity (kg/h):

-

1000 - 5000

-

Voltage:

-

380V/50HZ

-

Dimension(L*W*H):

-

65*6*5M

-

Power (kW):

-

210-260

-

Weight (T):

-

5

-

Name:

-

Plastic Granule Machines

-

Final product:

-

Granulating Production Line

-

Keywords:

-

Film Pelletizing Line

-

Raw material:

-

PP PE Film Bags Material

-

Capacity:

-

500-5000kg/h

-

Usage:

-

Granules Making Machine

-

Function:

-

Recycling Granulator

-

Hot search:

-

recycle plastic granules

-

Type:

-

Recycling Granulator

-

After Warranty Service:

-

Field maintenance and repair service

Description

Raw Material

Product details

Belt conveyor

Belt conveyor : PVC material

Metal detector is optional to prevent metal materials from entering the extruder with raw materials (film)

Metal detector is optional to prevent metal materials from entering the extruder with raw materials (film)

Compactor

Double layer cutting disc, more efficient feeding and 10% - 20% increase in output Hydraulic opening and hydraulic lifting, safe

and easy to maintain .

and easy to maintain .

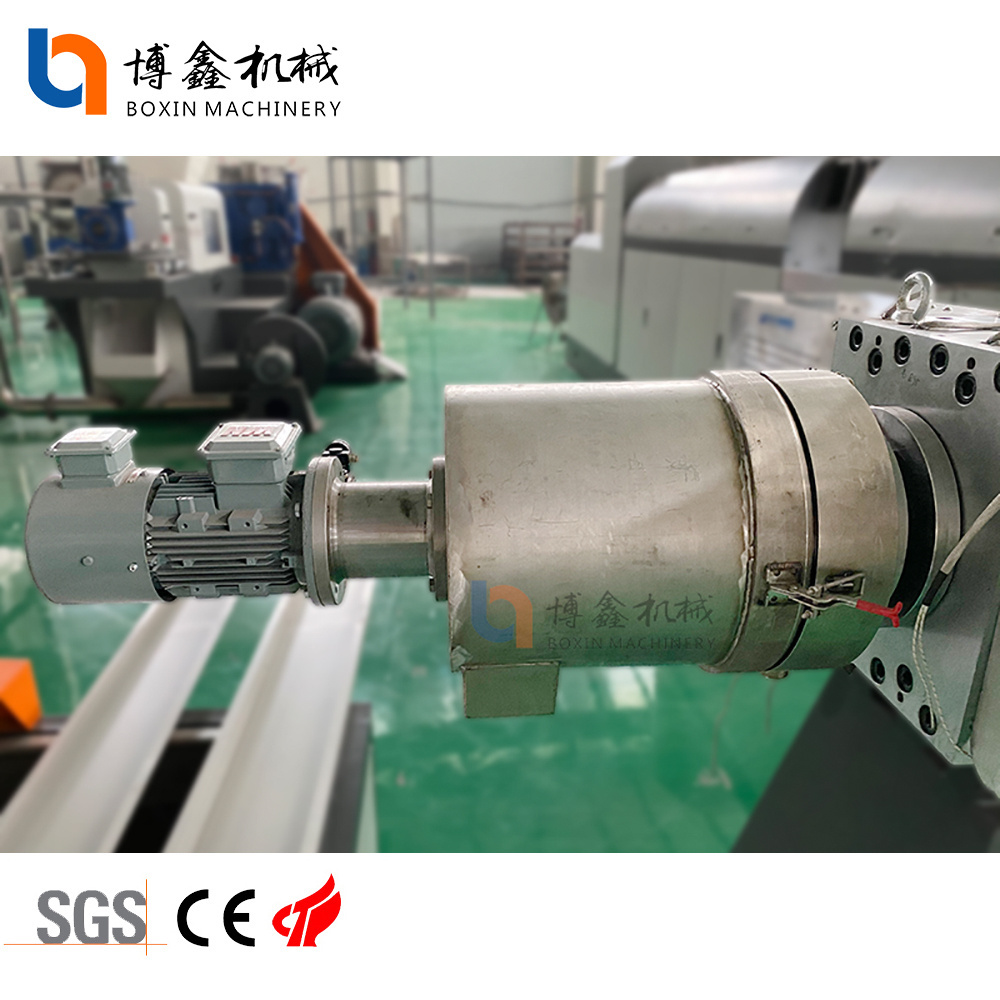

Single Screw Extruder

Screw and barrel : 38CrMoAl, nitriding treatment Heater : Ceramic + stainless steel cover Vacuum pump exhaust, double exhaust

Water Ring Cutting Machine

Die head material : 38CrMoAlA Material of water ring cover : stainless steel 304 Horizontal design with linear guide rail, easy

operation and maintenance Pneumatic adjustment makes the cutting blade in soft contact with the die surface, so as to achieve 100% contact between the blade and the die head and avoid die surface damage.

operation and maintenance Pneumatic adjustment makes the cutting blade in soft contact with the die surface, so as to achieve 100% contact between the blade and the die head and avoid die surface damage.

Vibrating Dehydrator

Several sizes of sieves are available for discharging from their respective outlets. Line screen fully enclosed structure, no dust and overflow, automatic discharge, etc., more suitable for 24 hour assembly line operation Low energy consumption, high output, simple structure and easy maintenance Combination of filtration and dehydration, high efficiency and power saving

Two Stage Granulator (Optional)

One stage granulator, two stage granulator which we are all supply

|

Model

|

BXC2-85

|

BXC2-100

|

BXC2-120

|

BXC2-150

|

BXC2-160

|

BXC2-180

|

|

Capacity(KG/H)

|

100-200

|

200-300

|

300-400

|

500-600

|

700-800

|

800-1000

|

|

L/D

|

1:33

|

1:33

|

1:33

|

1:36

|

1:36

|

1:36

|

|

Install Power(KW)

|

110

|

135

|

160

|

310

|

370

|

520

|

|

Compactor Power(KW)

|

37

|

45

|

55

|

110

|

132

|

185

|

|

Main extruder Power(KW)

|

55

|

75

|

90-110

|

185

|

220

|

280-315

|

|

Staff requirement

|

2-3

|

2-3

|

2-3

|

2-3

|

2-3

|

2-3

|

|

Overall size(L*W*H)

|

9*5*4

|

10*5*4

|

12*5*4

|

13*6*4

|

13*6*4

|

13*6*4

|

Welcome to BOXIN

Our Customers

Recommend Products

FAQ

HOW TO FIND BOXIN MACHINE?

● Search Alibaba, Made in China, Google, Youtube and Facebook.

● Visit exhibition in differentcountries

●

Send BOXIN Machine an request and tell your basic inquiry

● BOXIN Machine sales manager will reply you in short timeand add instant chatting tool

YOU ARE WELCOME TO OUR FACTORY AT ANY TIME.

● If we can fullfill your request and you interested inour products, you may pay a visit to BOXIN Machine site

● The meaning of visiting supplier, because seeing is believing, BOXINMachine with own manufacture and developed& research team, we can send you engineers and make sure your after sales service.

HOWTO GUARANTEE YOUR FUNDS TO BE SAFE AND DELIVERY TO BE ON TIME?

● Through Alibaba letter guarantee service, it will ensure the on time delivery and the quality of the equipment you want to buy.

● By letter of credit, you can lock the delivery time easily.

●After the factory visit, You can ensure the facticity of our bank account.

SEE BOXIN MACHINE HOW TO ENSURE THE QUALITY!

● In orderto ensure the accuracy of each part, we are equipped with a variety of professional processing equipment and we have accumulatedprofessional processing methods over the past years.

● Each component before assembly needs strictly control by inspectingpersonnel.

● Each assembly is in charged by a master who has working experience for more than 20 years

●After all the equipmentare completed, we will connect all the machines and run the full production line to ensure the stable running in customers'factory.

THE AFTER-SALE SERVICE OF BOXIN MACHINE!

● After finish the production, we will debug the production line, take photos,videos and send them to customers e-mail or instant tools.

● After the commissioning, we will package the equipment by standardexport package for shipment.

● According to the customer's request, we can arrange our engineers to customers' factory to do theinstallation and training.

● Engineers, sales managers and after-sales service manager will form a after-sales team, online andoff line, to follow the customers' project.

if you want to know more details about BOXIN machine ,welcome to send us an inqury now!

Hot Searches