- Product Details

- {{item.text}}

Quick Details

-

Marketing Type:

-

Hot Product 2023

-

Weight (KG):

-

2800 kg

-

Application:

-

recyclable aluminum alloy sorting machine

-

suitable industry:

-

valuable nonferrous recovery from waste

-

Aluminium Material containing:

-

Cast Items Extrusions Profiles Sheets Window Frames

Quick Details

-

Production Capacity:

-

Other

-

Applicable Industries:

-

green Aluminum Breakage recycling, Aluminum Breakage alloy profiles scraps recycling, Extrusions Profiles Sheets Window Frames recycling, aluminum beverage cans sorting, aluminum alloy profiles scraps recycling processes, Secondary aluminium recycling processes, Shredded Aluminium Tense Scrap recycling processes, wrought aluminium recycling processes, shredded green aluminium scraps recycling process, ZORBA fraction recycling plant, wrought aluminium scraps recovery, Aluminum electric motor recycling, crushed Electrical engineering scraps recycling

-

Place of Origin:

-

China

-

Marketing Type:

-

Hot Product 2023

-

Weight (KG):

-

2800 kg

-

Application:

-

recyclable aluminum alloy sorting machine

-

suitable industry:

-

valuable nonferrous recovery from waste

-

Aluminium Material containing:

-

Cast Items Extrusions Profiles Sheets Window Frames

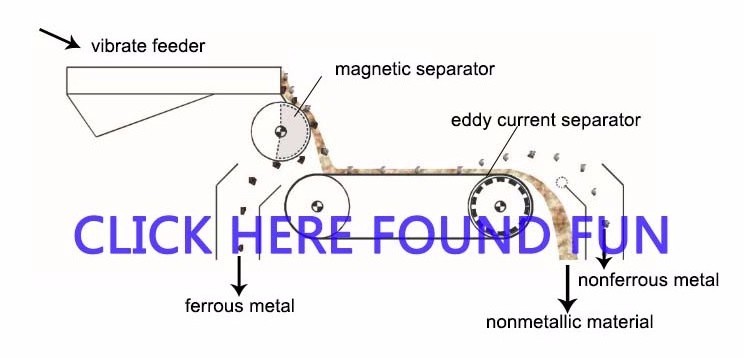

Automatic magnetic eddy current aluminum alloy separation machine widely used in secondary aluminum recycling industry could effectivily sorting the cast and wrought from casting waste scraps that from shreeding processing in aluminum ignot manufacturing .

This metallics recycling system is composited by eddy current aluminum scraps separator and high intensity drum type ferromagnetic separator, most suitable for separate metal scraps (such as steel , copper, aluminum and other non-ferrous metals) from waste residential stream, often be installted in various of fragmentiser plant for crushed metal scraps recycling

Other application of Magnetic eddy current mixed metal recycling machine

1.Recovery recyclable metallics material from various of auto shredding mixed metal scraps yard. such as in End-of-Life vehicle (ELVs) /domestic application recycling industry , automobile shredded residue(ASR)recycling industry , waste incineration facilities ,steel slag scraps recycling industry .

2.Removes mixed metallics from plastics, glass cullet, electronic scrap, , boiler bottom ash, spent foundry core sand, municipal solid waste (MSW), co-mingled recyclables, urban wood waste and mixed metals , providing a cleaner product for further processing.

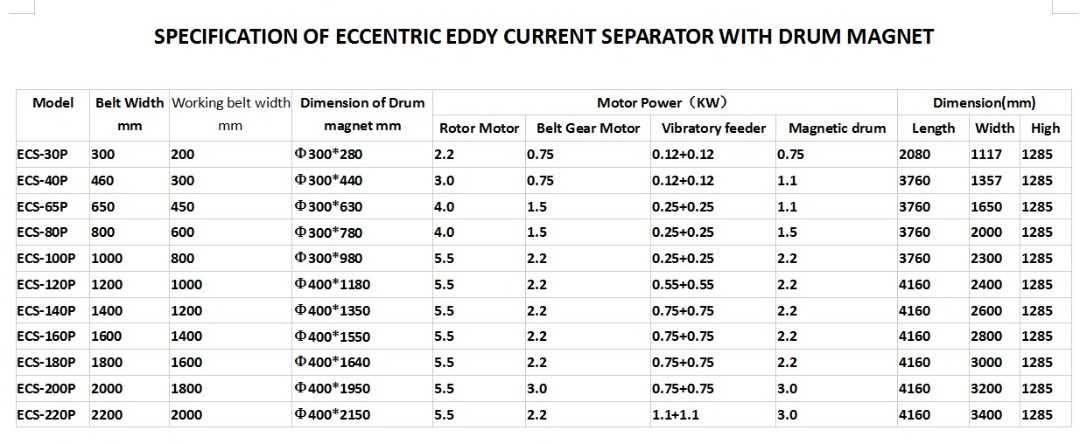

Specification of eddy current mixed scraps metal recycling machine /system

working plant of soring non-ferrous metal and creating top qualities for shredding scraps recycling

|

Working site inJapan /Thailand for Zorba processing

|

|

best-in-class ferrous and non-ferrous recovery rates for shredding operations.

|

|

Zorba purification

|

|

AUTOMOBILE shredder-residue ASR SHF SLF Fluff processing system for metal recovery

|

Separation materials display:

|

aluminum/copper caps and rings separated from crushed glass bottles scrap |

aluminum/copper recovery from recyclable plastic scrap |

aluminum removal from rubber scraps/powder |

| UBC(Beverage cans) sorting |

aluminum scrap recovery from molding sand |

to Separate non-ferrous metals from wood waste |

1.Packing:Export packing for magnetic non-ferrous metal separator

2.Shipping time: 60days after receive the deposit

As a professional manufactures of eddy current separator ,magnetic separator , sensor stainless steel sorter etc metals separation machine / system and vibratory feeder , trommel screen , belt conveyor etc handling and conveyor machine since 2006 . honesty, reliability, commitment and competence are our unchanged values.

Thanks to the superior suppliers (Nord,Simens &Schneider) ,well-equipped professional engineers and strong technical force, we keep our consistent high quality.strict quality checked for every machine before packing, engineers available to service machinery overseas, inaddition, there is not only after sales service support, but also technology support, "keep improing, persuing excellence" would be keep forever

we can design and manufacture completely metal solution line or simply furnish eddy current non-ferrous separato or any other piece of magnetic separation equipment.

Non-ferrous Separator Perm Magnetic Separator ElectroMagnetic separator Overhand Magnectic Separator

Magnetic Pulley Magnetic Drum Dry Magnetic Separator Wet Magnetic Separator

Magnetic Grid Magnetic Grate Separator Magnetic Chute Liquid Magnetic Trap

RFQ

Q: What kind of metal is eddy current applied to?

A: Eddy Current Separator suitable for aluminum, copper, brass .etc non-ferrous scraps separation from non - metal materials of size >3mm.

Q: Which type should I use for my recycling plant?

A: In order to recommend the most suitable model , please let us know the m aterial `s situation . including the composition , size , handling capacity and expected separation result .

Q: What are the pros and cons between a concentric pole rotor compared with and eccentric rotor design?

A: The eccentric type is much suitable for complicated material situation , The eccentric rotor design reduces long-term wear due to heated ferrous build up ,can effectively avoid the device damage caused by impurity ferrous metal.

Exclusive the ferrous influence , the concentric type have a little bit better separation effect,but must make sure no ferrous exist.