- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

DM-YK63

-

Power (kW):

-

7.1, 11, 15, 22

-

Weight (KG):

-

2000

-

Application:

-

Press Scrap Metal

-

Keyword:

-

Horizontal Metal Baler

-

Function:

-

Waste Metal Baling

-

Usage:

-

Metal Pressing Machine

-

Driven Type:

-

Hydraulic Pressure

-

Raw material:

-

Scrap Metal Aluminum Copper

-

Material:

-

Steel Material

-

Type:

-

Fully Automatic

-

BALE SIZE:

-

Optional

Quick Details

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Domax

-

Marketing Type:

-

Hot Product 2024

-

Model Number:

-

DM-YK63

-

Power (kW):

-

7.1, 11, 15, 22

-

Weight (KG):

-

2000

-

Application:

-

Press Scrap Metal

-

Keyword:

-

Horizontal Metal Baler

-

Function:

-

Waste Metal Baling

-

Usage:

-

Metal Pressing Machine

-

Driven Type:

-

Hydraulic Pressure

-

Raw material:

-

Scrap Metal Aluminum Copper

-

Material:

-

Steel Material

-

Type:

-

Fully Automatic

-

BALE SIZE:

-

Optional

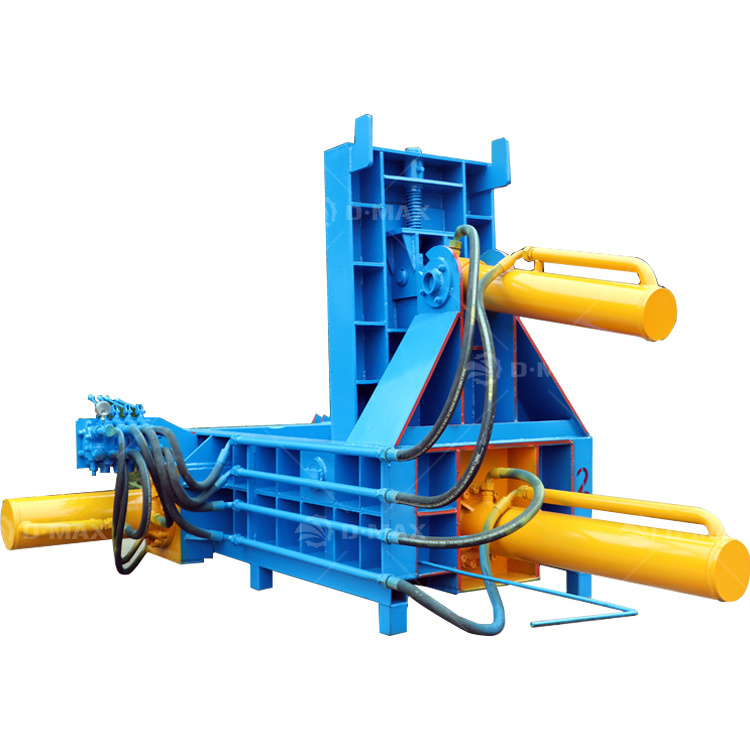

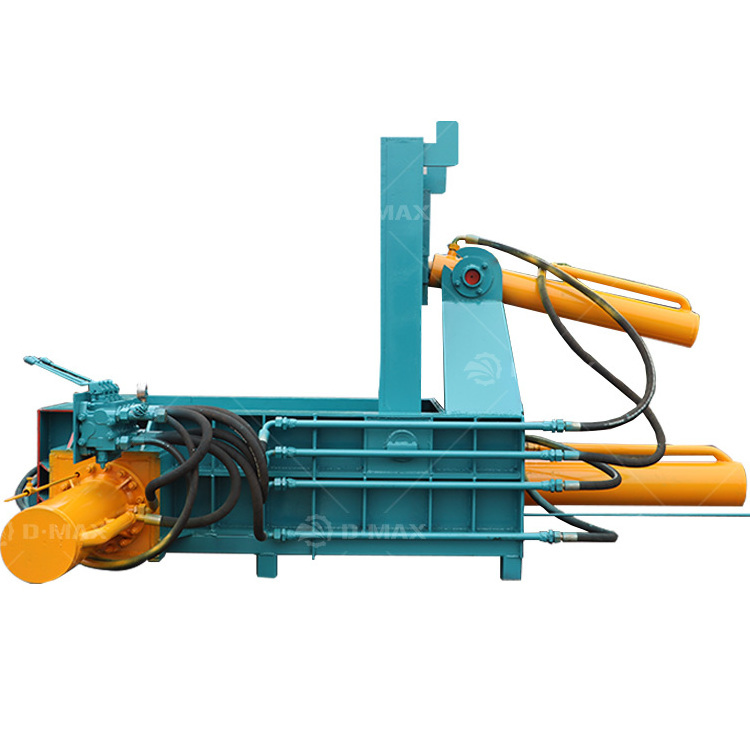

Metal Packing Machine Can Briquetting Machine Scrap Steel Scrap Metal Baler Metal Baling And Briquetting Machine

Introduction of the metal block pressing machine

Metal baler machine is mainly used in recycling industry and metal smelting industry.It can be used to squeeze all kinds of metal scraps, steel shavings, scrap steel, scrap iron, scrap copper, scrap aluminum, aluminum shavings, dismantled automobile shells, waste oil barrels and other metal raw materials into square, cylindrical and other shapes. ,Easy to store, transport and re-use, improve the speed of casting, increase labor efficiency, reduce transportation, manpower, smelting costs.

Application of the metal block pressing machine

Mainly used in the recycling and processing industry and metal smelting industry. Various metal scraps, steel shavings, scrap steel, scrap iron, scrap copper, scrap aluminum, aluminum shavings, car shells, waste oil drums, and other metal raw materials can be extruded into rectangular, cylindrical and other shapes of furnace materials for easy storage, transportation, and recycling.

Advantages of the metal block pressing machine

1.The discharging types fall into turning over, push out ,forward out and manual lifting;

2.It is unnecessary to fix foot screw and a diesel engine can be used in case of power supply unavailability;

3.Smooth operation; computer control, high degree of automation, low failure rate, easy maintenance and so on;

4.The extrusion force ranges from 63t to 400t ,totaling 10 grades for customers' selection ,and productivity being from 3.2t/shift to 64t/shift.

Parameters

|

Model

|

Nominal force

|

Tank size

|

Block size

|

Block weight

|

Capacity

|

Power

|

|

DM-YK63

|

630

|

1000*600*500mm

|

190*190mm

|

15-30kg

|

0.4-0.8t/h

|

7.1kw

|

|

DM-YK100

|

1000

|

1000*700*550mm

|

230*230mm

|

30-40kg

|

0.6-1.2t/h

|

11kw

|

|

DM-YK125

|

1250

|

1200*700*600mm

|

300*300mm

|

50-75kg

|

1.2-1.5t/h

|

15kw

|

|

DM-YK135

|

1350

|

1400*600*600mm

|

600*240mm

|

60-80kg

|

1.5-2.8t/h

|

22kw

|

|

DM-YK160

|

1600

|

1600*1000*800mm

|

400*400mm

|

110-150kg

|

2.2-3.0t/h

|

22kw

|

|

DM-YK200

|

2000

|

1800*1400*900mm

|

450*450mm

|

210-300kg

|

3.0-5.0t/h

|

22*2kw

|

|

DM-YK250

|

2500

|

2000*1750*1000mm

|

500*500mm

|

250-280kg

|

5.0-6.3t/h

|

22*2kw

|

|

DM-YK315

|

3150

|

2500*2000*1200mm

|

500*500mm

|

250-360kg

|

4.0-6.5t/h

|

37*2kw

|

|

DM-YK400

|

4000

|

3000*2000*1200mm

|

500*600mm

|

250-380kg

|

6.8-8.0t/h

|

45*2kw

|

Machine Pictures Display

Packaging & Delivery

Recommend Products

Customer Feedback

Why Choose Us

Contact Us

Advantages

Hot Searches