- Product Details

- {{item.text}}

Quick Details

-

Material:

-

Aluminium

-

Brand Name:

-

XYM

-

Place of Origin:

-

Guangdong, China

-

part name:

-

large machining service

-

MOQ:

-

1 Piece

-

Lead time:

-

Sample: 3-5 day; Production: 10-20 days.

-

Processing method:

-

CNC machining, polishing, anodize

-

Tolerance:

-

+/-0.01mm

-

Surface treatment:

-

Andozing

-

Payment Terms:

-

30% desposite, 70% before shipping

-

Packing:

-

Carbon Box

-

Volume:

-

1-1000L Customized

Quick Details

-

Applicable Industries:

-

Manufacturing Plant, Other

-

Structure:

-

Metal Bellows

-

Standard or Nonstandard:

-

Nonstandard

-

Material:

-

Aluminium

-

Brand Name:

-

XYM

-

Place of Origin:

-

Guangdong, China

-

part name:

-

large machining service

-

MOQ:

-

1 Piece

-

Lead time:

-

Sample: 3-5 day; Production: 10-20 days.

-

Processing method:

-

CNC machining, polishing, anodize

-

Tolerance:

-

+/-0.01mm

-

Surface treatment:

-

Andozing

-

Payment Terms:

-

30% desposite, 70% before shipping

-

Packing:

-

Carbon Box

-

Volume:

-

1-1000L Customized

Mechanical / Structure Parts One-Stop Manufacturer

CNC machining / Mold-Tooling / Metal Parts / Plastic Parts / Assembly

Many designer and start up company have amazing ideas and new products includes plastics, metals, electronics components and so on. But how to find a professional and reliable manufacturer to help them make their ideas come true? You might be one of them?

DGHY Tmetal is a good choice for you!

We offer not only custom parts service, tool & die mold design and manufacturing, casting and injection molding production, sheet metal fabrication, but also offer final product assembly service. We can help your project from prototyping, trial run, to final smooth mass production. OEM, ODM both are welcome.

DGHY quite understand prototyping phase is very important for you to find out where the designs' problem is, our engineering technical team will give strong support from design improving to process improving, until get your prototype done perfect.

For custom parts manufacturing, generally, we make prototype by CNC machining in our CNC Machine shop.

CNC machining / Mold-Tooling / Metal Parts / Plastic Parts / Assembly

Many designer and start up company have amazing ideas and new products includes plastics, metals, electronics components and so on. But how to find a professional and reliable manufacturer to help them make their ideas come true? You might be one of them?

DGHY Tmetal is a good choice for you!

We offer not only custom parts service, tool & die mold design and manufacturing, casting and injection molding production, sheet metal fabrication, but also offer final product assembly service. We can help your project from prototyping, trial run, to final smooth mass production. OEM, ODM both are welcome.

DGHY quite understand prototyping phase is very important for you to find out where the designs' problem is, our engineering technical team will give strong support from design improving to process improving, until get your prototype done perfect.

For custom parts manufacturing, generally, we make prototype by CNC machining in our CNC Machine shop.

For trial run, if quantity not large, CNC machining still is a better way to choose.

Mass production will need open Die mold(Tooling), this way production capacity will increase a lot, product cost will get much cheaper and quality will be more stable as well.

DGHY offer you one-stop manufacturing solution, we have our own Mold Tooling workshop, CNC machining shop, die casting shop, plastic injection shop and sheet metal fabrication shop, this enable us could help you saving your project management cost and time, and make your products to be more competitive in the market!

Mass production will need open Die mold(Tooling), this way production capacity will increase a lot, product cost will get much cheaper and quality will be more stable as well.

DGHY offer you one-stop manufacturing solution, we have our own Mold Tooling workshop, CNC machining shop, die casting shop, plastic injection shop and sheet metal fabrication shop, this enable us could help you saving your project management cost and time, and make your products to be more competitive in the market!

|

Item

|

Gear Shift Knob

|

|

|

|

|

Main Equipment

|

CNC Machining center 3,4 and 5 axis (Haas Fanuc Brther), CNC lathe(CITIZEN,Tsugami), Grinding machine, Cylindrical grinder machine, Drilling machine, Laser cutting machine, EDM machine, etc.

|

|

|

|

|

Material

|

Aluminum, Stainless steel, brass, copper, carbon steel, beryllium copper, titanium alloy, plastic, etc.

|

|

|

|

|

Processes

|

CNC turning, CNC milling

|

|

|

|

|

Surface Treatment

|

Anodizing, Knurling, Brush, Sand blasting, High polished, Plating, Powder coating, Painting, Electroplating, Silk screen, Engrave,

etc. |

|

|

|

|

Inspection Equipment

|

Callipers, Micrometer, altimeter, CMM(3D coordinate measuring machine PC dmis), Dantsin TRIMOS V5

2.0 D measurement Instrument, go-no go gauges, Thread gauge |

|

|

|

|

Tolerance

|

±0.003

|

|

|

|

|

QC Control

|

100% inspection before shipment

|

|

|

|

|

Drawing format

|

JPG, PDF, CAD, DWG, STP, STEP, IGS

|

|

|

|

|

Lead time

|

3-5 working days for samples, 10-20 days for mass production

|

|

|

|

|

Packaging

|

Regular: Paper, Foam, PE bag, EPE form, Carton;

Other: According to customers' requirements |

|

|

|

|

Payment Terms

|

50% T/T in advance, 50% balance before shipment

|

|

|

|

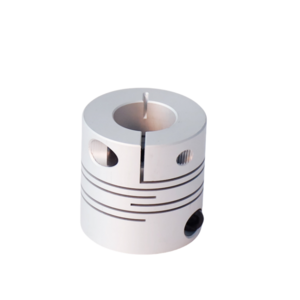

Rigid Split Muff Aluminium Coupling

Shaft Slit Parallel Lines Aluminum Coupling

Aluminum Alloy Flexible Shaft Coupling

Hot Searches