- Product Details

- {{item.text}}

Quick Details

-

Power:

-

2500W

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

ETERNE

-

Maximum Digging Height:

-

9616MM, 10650mm

-

Maximum Digging Depth:

-

6411MM, 7850mm

-

Machine Weight:

-

12000 kg

-

Max Digging Radius:

-

3000MM

-

Rated Speed:

-

0.5M/S

-

Pontoon Width:

-

1500m

-

Power(W):

-

86kW

-

Minimum Ground Clearance:

-

1170mm

Quick Details

-

Operating Weight:

-

50 Ton, 40 ton

-

Bucket capacity:

-

1.15m³

-

Engine Brand:

-

Cummins

-

Power:

-

2500W

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

ETERNE

-

Maximum Digging Height:

-

9616MM, 10650mm

-

Maximum Digging Depth:

-

6411MM, 7850mm

-

Machine Weight:

-

12000 kg

-

Max Digging Radius:

-

3000MM

-

Rated Speed:

-

0.5M/S

-

Pontoon Width:

-

1500m

-

Power(W):

-

86kW

-

Minimum Ground Clearance:

-

1170mm

40 ton Amphibious Excavator swamp buggy excavator with floating pontoon

Product Overview

ET-215 Amphibious water floating excavator

Plain marshland management and low-yield land reconstruction, water diversion project and saline alkali land reconstruction and urban water supply and water supply projects; beach treatment and sea- related engineering.

shallow sea oil and gas well location engineering, tailings, photovoltaic engineering, reclamation, dredging Excavation, dredging, slope repairing.embankment, drainage pipe erection, flood control and rescue in dredging.

shallow sea oil and gas well location engineering, tailings, photovoltaic engineering, reclamation, dredging Excavation, dredging, slope repairing.embankment, drainage pipe erection, flood control and rescue in dredging.

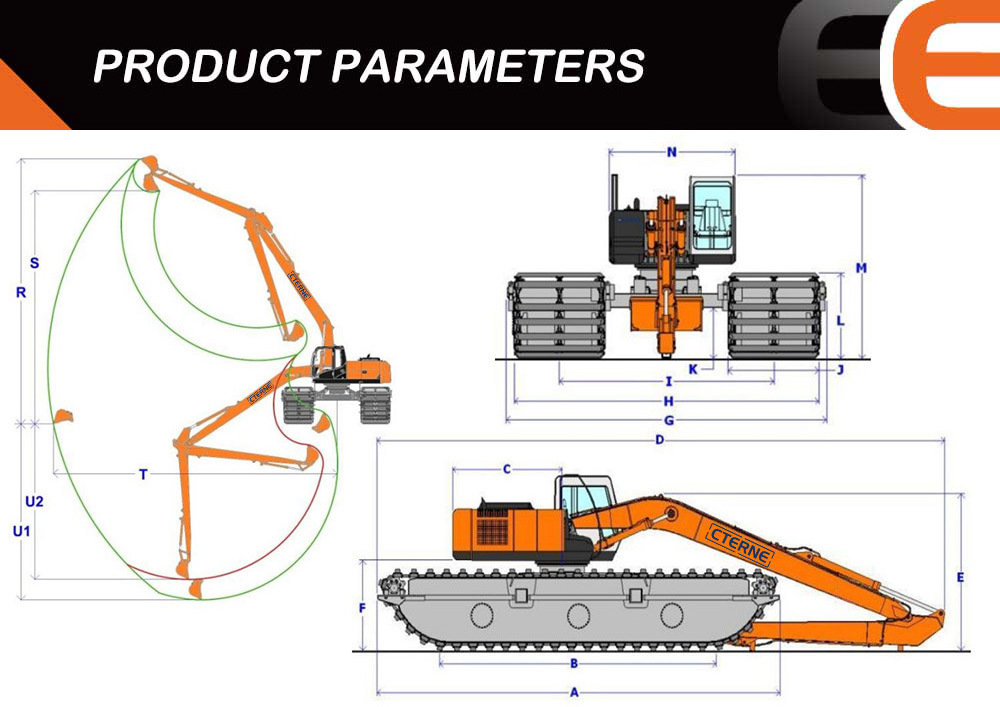

PRODUCT SPECIFICATIONS

|

Description

|

Standard parameter

|

|

Maximum Ground Digging Distance

|

9,810 mm

|

|

Maximum Horizontal Digging Distance

|

9699 mm

|

|

Maximum Cutting Height

|

9616 mm

|

|

Maximum Vertical Digging Depth

|

5929 mm

|

|

Maximum Digging Depth

|

6411 mm

|

|

Minimum Turning Radius

|

3,000 mm

|

|

Undercarriage Length

|

8500mm

|

|

Counterweight Ground Clearance

|

2035mm

|

|

Overall Height ( to the top of the cab)

|

3990mm

|

|

Overall Height ( to the top of the boom)

|

3970mm

|

|

Overall Length

|

11721mm

|

|

Tail Turning Radius

|

2794mm

|

|

Track Gauge

|

3500mm

|

|

Overall Width

|

5400mm

|

Technical details

The material of the pontoon is AH36 ship-specific material and 6061T6 aluminum alloy high-strength plate. Sanding and shot blasting technology is used in anti-corrosion treatment to effectively improve the service life. Reasonable structural design and on-site destructive tests ensure the bearing capacity and safety of the floating tank. The pressure groove of the pontoon prevents the deformation of the surface of the pontoon due to long-term work and the complexity of the working conditions, thereby reducing the service life, which is both beautiful and practical.

After the chain has been used for a period of time, the wear of the pin sleeve will cause the pitch to increase and the whole chain will become longer, which will cause the chain to drop or slip during walking, which will seriously affect the operation. The tensioning device can adjust the position of the sprocket to ensure the normal engagement of the chain pin and the drive gear teeth. Screw tightening is the standard configuration of our company's pontoon, and oil cylinder tensioning is easier to operate than screw tensioning. The tensioning force can achieve balance adjustment, making the entire walking system work more stable and efficient.

The expansion and contraction of the pontoon is a patented design of our company, which means that the operating system can adjust the distance between the two pontoons arbitrarily within a certain range. The hydraulic control system is installed in the connecting beam of the two pontoons, which is easy to operate and has high safety. In the construction process, if encountering a relatively narrow working environment, the distance between the two pontoons can be reduced to the minimum, and the construction can be carried out as usual. Adjust the distance between the two pontoons to an appropriate size in a wide area to enhance the stability of the chassis and improve work efficiency.

Our Advantages

Packing & Delivery

Our Story

Shandong Eterne Machinery Co., Ltd. is a modern enterprise from Weifang City, Shandong Province, China.

Our factory has 17 years of experience in the production and sales of mining equipment and dredgers. The products have been sold all over the country and exported to more than 50 countries including Bangladesh, the Philippines, Indonesia, Malaysia, Suriname, Bolivia, Ecuador, Nigeria, South Africa, Mali, Tanzania, etc. If this is your first time importing equipment from China, our rich experience can help you solve all the problems.

We have our own design team that can design and develop independently. You can send us the picture of your mine, and we can develop a one-stop reasonable and feasible mining plan according to your requirements and geographical environment.

FAQ

1: Terms of payment?

L/C, T/T, D/A, D/P, Western Union (can be) could accepted

2: What certificates are available?

we have CE, ISO, EPA(USA), CCC;

3: What about the delivery time?

7-20 days after receiving the deposit.

4: What about the warranty time?

For tracks, 6 months after shipment or 1000 working hours, for pontoons,

12 months after shipment or 2000 working hours, whichever occurs first.

5. what about OEM?

OEM is accepted

L/C, T/T, D/A, D/P, Western Union (can be) could accepted

2: What certificates are available?

we have CE, ISO, EPA(USA), CCC;

3: What about the delivery time?

7-20 days after receiving the deposit.

4: What about the warranty time?

For tracks, 6 months after shipment or 1000 working hours, for pontoons,

12 months after shipment or 2000 working hours, whichever occurs first.

5. what about OEM?

OEM is accepted

Hot Searches