20bar MNH-6160A gas nitrogen membrane generator for oil plant

-

Transport Package:

-

Standard export packaging

-

Specification:

-

60cm*60cm*225cm

-

Trademark:

-

KL AIER AIR DRYER

- Product Details

- {{item.text}}

Quick Details

-

Origin:

-

Hangzhou China

-

Warranty:

-

3 months

-

Flow:

-

Parallel Flow

-

Material Status:

-

Other

-

Drying Medium:

-

Air

-

Structure:

-

Other

-

Operation Pressure:

-

Atmospheric Pressure

-

Inlet Temperature:

-

High Temperature

-

Cooling Way:

-

Other

-

Type:

-

Medium

-

Payment:

-

L/C T/T

-

Export Port:

-

SHANGHAI NINGBO

-

Output:

-

1000pieces/year

-

Model NO:

-

MNH-6160A

Quick Details

Product overview

20bar MNH-6160A gas nitrogen membrane generator for oil plant

The nitrogen generator is connected to compressed air and undergoes three-stage filtration, Clean air after removing liquid water, particulate matter, and oil moisture The electric heater is heated to 45 ℃ and enters the nitrogen magic separation process, Obtain 95~99% high-purity nitrogen gas. The system is controlled by PLC for easy operation.panel display: parameters such as flow rate, purity, temperature, etc.

Replacing bottled nitrogen or liquid nitrogen, reducing production costs, improving cutting quality and efficiency.

MNH-6160A inside with nitrogen membrane pipe, three filters, PLC system and gas analysis, good matching for 16bar air compressor line connection to laser cutting line.

Features at a glance

|  |

Component

|  |  |

| Side photo | Front and right side photo | Inside photo |

KL-AIR nitrogen membrane module:KL NOM nitrogen generator could matching for 16bar air compressor , after the pressure drop, the out pressure could perfect get 13~15bar. N2 gas out pure 97~99% is also perfect meet the laser cutting line for metal materials cutting. About 100W power consume is also saving the cost for factory. |  |

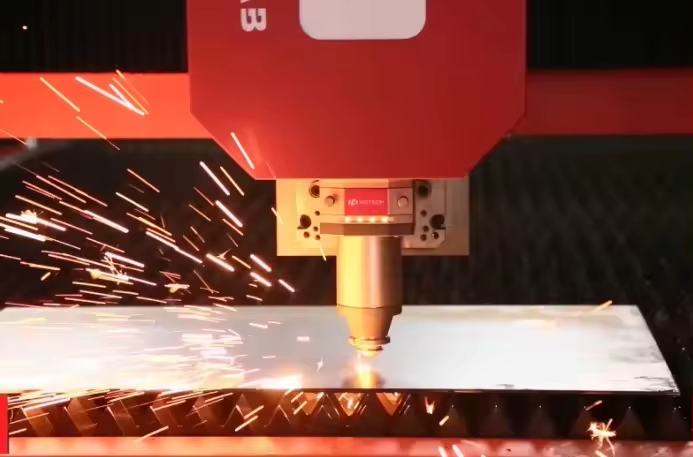

Laser cutting line----Metal cutting:

The laser cutting machine need the nitrogen gas for the protection, use the N2 gas could get the bright & smooth cutting surface.

liquid nitrogen is expensive. and factory need pay attention for safety use & stock. Usually, the cutting line they donot need high pure liquied nitrogen. 97~99% is perfect. but the puressure is need 12~14bar.

PSA gas generator out pressure is 6~8bar, if use the PSA system, user need add a gas compressor for their laser cutting line.

Specification table

No | Pure % | Flow rate Nm3/h | Pressure Bar | Dew point Deg.C | Power |

1 | 99 | 23 | 13~16 | -20 | 2.2 |

2 | 98 | 33 | 13~16 | -20 | 2.2 |

3 | 97 | 44 | 13~16 | -20 | 2.2 |

4 | 96 | 54 | 13~16 | -20 | 2.2 |

5 | 95 | 65 | 13~16 | -20 | 2.2 |

Product Configuration

PLC controller & touch screen |  Nitrogen membrane pipe |  Compressed air filter |

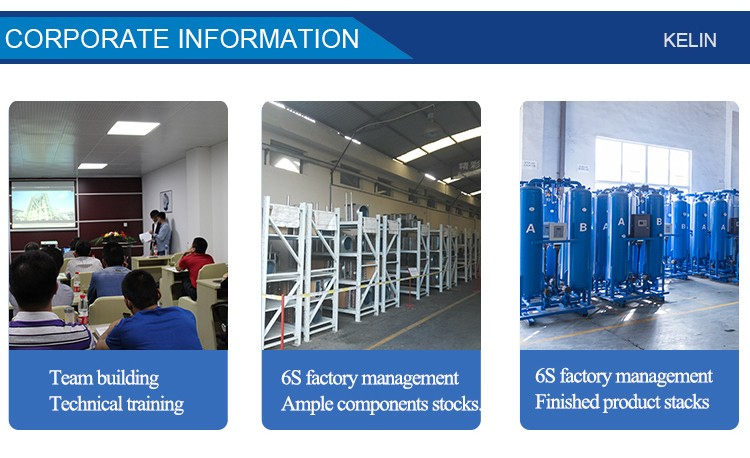

Company profile

Exhibition

Packaging&shiping

FAQ

1. Are you manufacturer or Trade Company?

We are OEM professional air dryer, founded in 1997.

Leading products: compressed air dryer, desiccant air dryer, air filter, water chiller, PSA gas generator.

2. What terms of payment you use?

T/T, L/C

3. Do you have any instant chat tool?

Any Inquiry or question, pls contact:

Hangzhou Kelin Aier Qiyuan Equipment Co.ltd

Main Product: air dryer & water chiller & gas generator etc.

Add:Anxi Industrial Zone,Liangzhu,Yuhang,Hangzhou,China