- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

380V

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

JKPACK

-

Dimension(L*W*H):

-

1800mm*1590*1620mm

-

Weight:

-

1200KG

-

After-sales Service Provided:

-

Engineers available to service machinery overseas, Online support, Video technical support, Free spare parts, Field installation, commissioning and training, Field maintenance and repair service

-

Machine type:

-

Automatic Rotary Bag Given Packing Machine

-

Machine material:

-

SS304/SS316

-

Bag type:

-

Laminated film premade bag

-

Installation:

-

7 days

-

Payment item:

-

TT 30%,70% before shipping

-

Factory/CNC:

-

YES

-

Certification:

-

CE/IOS

Quick Details

-

Machinery Capacity:

-

8000BPH, 12000BPH, 16000BPH

-

Packaging Material:

-

Paper, Plastic

-

Filling Material:

-

Milk, Water, Oil, Juice

-

Voltage:

-

380V

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

JKPACK

-

Dimension(L*W*H):

-

1800mm*1590*1620mm

-

Weight:

-

1200KG

-

After-sales Service Provided:

-

Engineers available to service machinery overseas, Online support, Video technical support, Free spare parts, Field installation, commissioning and training, Field maintenance and repair service

-

Machine type:

-

Automatic Rotary Bag Given Packing Machine

-

Machine material:

-

SS304/SS316

-

Bag type:

-

Laminated film premade bag

-

Installation:

-

7 days

-

Payment item:

-

TT 30%,70% before shipping

-

Factory/CNC:

-

YES

-

Certification:

-

CE/IOS

Products Description

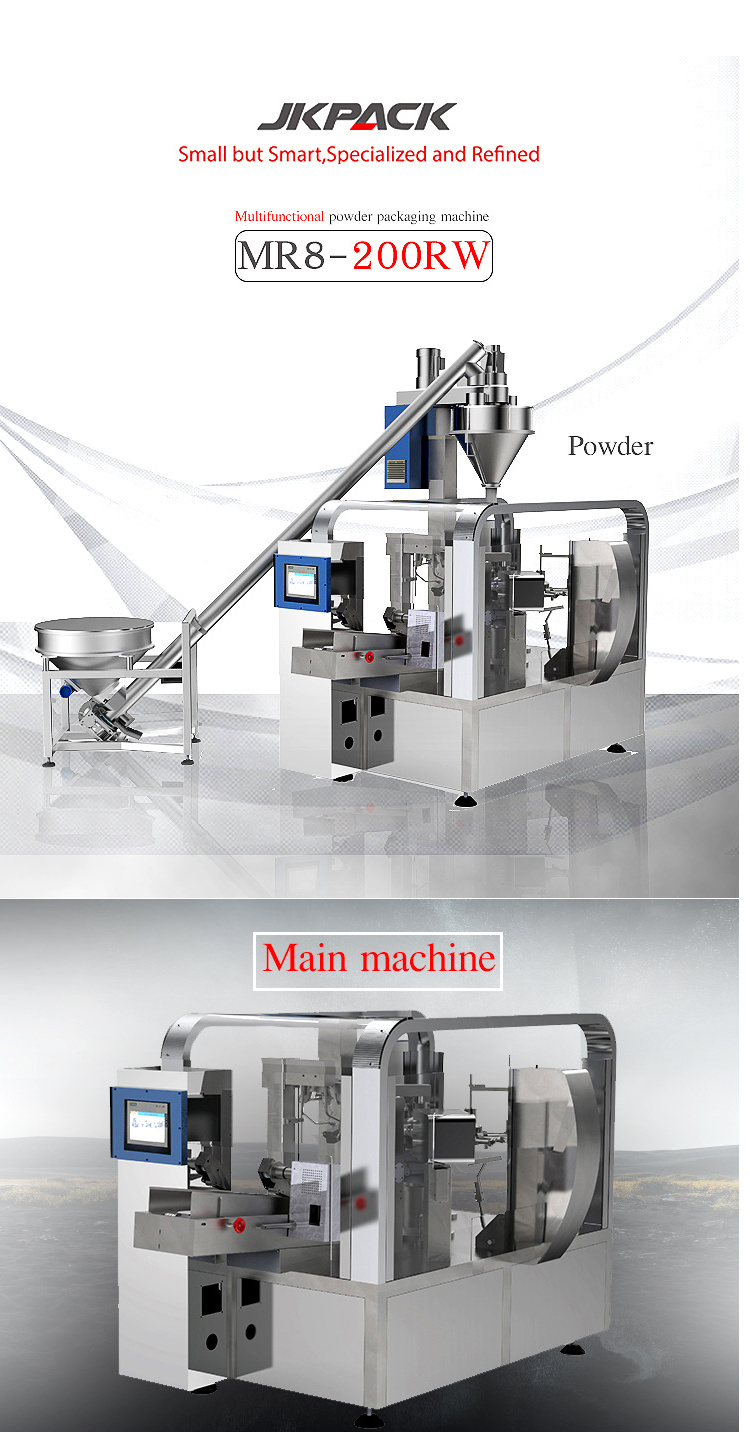

MR8-200RW Juice Spout Pouch Filling Machine

Full automatic preformed bags packaging system suitable for large and medium size production industries. Typical advantages of preformed pouch packaging system are minimum material wastage, easy product and bag size changeover, better sealing property especially for boil-in-bag and pasteurize bag products, excellent packaging presentation. Versatile and suitable for all types of preformed bags packing including side seal bags, fin seal bags, gusseted bags, block bottom bags, zip-lock reclose bag, stand-up pouch with or without spout etc, only by quick adjustment without size parts change over . Operators’ friendly in design. Easy to clean and low in maintenance. Complying with GMP standard, all product contact parts are in stainless steel or food grade

materials. State-of-the art picture and touch screen electric control system. Wash down and anti-rust construction. Possibility to link-up and synchronize with other up and down stream packaging equipment.

materials. State-of-the art picture and touch screen electric control system. Wash down and anti-rust construction. Possibility to link-up and synchronize with other up and down stream packaging equipment.

Product Paramenters

|

MR8-200RW Juice Spout Pouch Filling Machine

|

|

|

|

Model

|

MR8-200RW (smart/ordinary)

|

|

|

No. of working stations

|

Eight

|

|

|

Bags size

|

W:50~210mm L:100~300mm

|

|

|

Capacity

|

50-60 bags/min (The speed depends on type of products and packaging material used)

|

|

|

Total power consumption

|

2.5KW

|

|

|

Demension

|

2500*1590*1620mm

|

|

|

Compress air requirement

|

0.6m³/min supply by user

|

|

|

Pouch Type

|

All type of heat sealable preformed side seal bags, gusseted bags, block bottom bags,zip-lock recloseable bags, stand-up pouch

with or without spout etc.

|

|

Recommend Products

Hot Searches