- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Win Tone

-

Voltage:

-

380v, 380V/50HZ

-

Dimension(L*W*H):

-

600*500*1200mm

-

Weight:

-

120 KG

-

Product name:

-

Trilladora de maiz

-

Application:

-

Maize Peeler

-

Material:

-

Maize wheat millet sorghum

-

Function:

-

Corn Maize Threshing

-

Capacity:

-

300-500kg/h

-

Power:

-

4kw

-

Usage:

-

Home

-

Shelling rate:

-

95%

-

Final products:

-

Peeled Corn Maize Millet

Quick Details

-

Type:

-

Grain peeling machine

-

Use:

-

Corn bran shelling and peeling

-

Production Capacity:

-

95%

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Win Tone

-

Voltage:

-

380v, 380V/50HZ

-

Dimension(L*W*H):

-

600*500*1200mm

-

Weight:

-

120 KG

-

Product name:

-

Trilladora de maiz

-

Application:

-

Maize Peeler

-

Material:

-

Maize wheat millet sorghum

-

Function:

-

Corn Maize Threshing

-

Capacity:

-

300-500kg/h

-

Power:

-

4kw

-

Usage:

-

Home

-

Shelling rate:

-

95%

-

Final products:

-

Peeled Corn Maize Millet

Video Description

PRODUCT DESCRIPTION

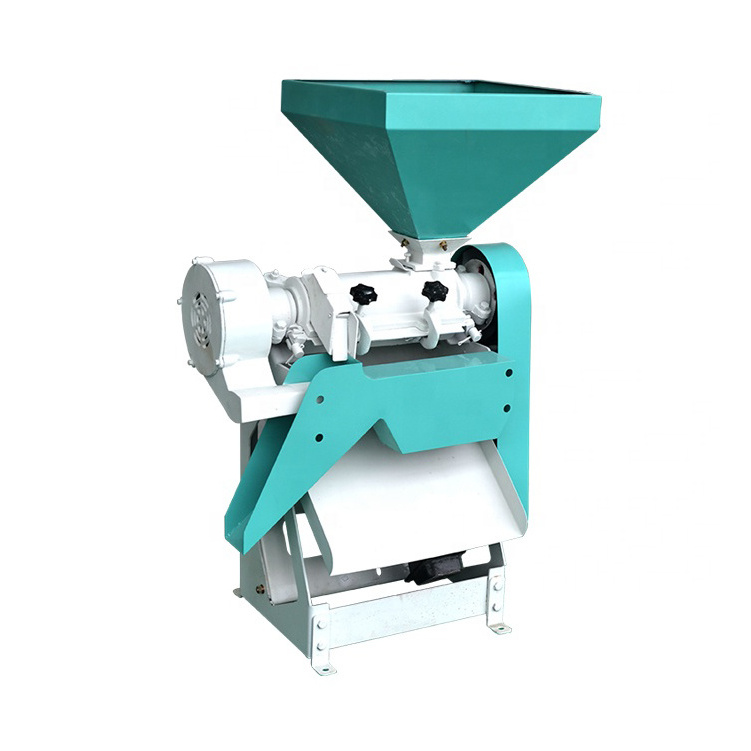

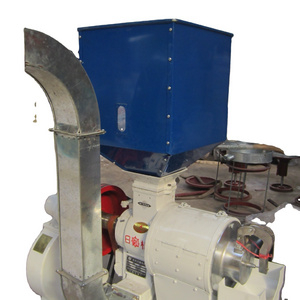

6NF-90 multifunctional corn maize peeler machine maize degerminator

Patent No.: ZL 2010 2 0689527.7

Corn peeler/corn degerminator working principle:

The machine includes 5 parts: charge hopper, hulling case, transmission device, separating device, and machinery rack.

Corn is sent into machine through charging hopper, and then is sent to hulling case by the screw propeller. The hulling case can produce big pressure, and the germ and bran of corn can be peeled off by the friction between roller and sieve.

The discharging outlet has grain purifying device, which can remove the micro bran further. And there has highly efficient air suction chamber installed inside of the machine which can clean the bran from the peeling process.

The discharging outlet of the peeling chamber can control the staying time in the peeling chamber for the corn and wheat, which can ensure effective friction between the grains and the alloy roller and realize better peeling effect.

The machine includes 5 parts: charge hopper, hulling case, transmission device, separating device, and machinery rack.

Corn is sent into machine through charging hopper, and then is sent to hulling case by the screw propeller. The hulling case can produce big pressure, and the germ and bran of corn can be peeled off by the friction between roller and sieve.

The discharging outlet has grain purifying device, which can remove the micro bran further. And there has highly efficient air suction chamber installed inside of the machine which can clean the bran from the peeling process.

The discharging outlet of the peeling chamber can control the staying time in the peeling chamber for the corn and wheat, which can ensure effective friction between the grains and the alloy roller and realize better peeling effect.

|

Model

|

Yield

(KG/H)

|

Power

(KW)

|

Rated Voltage (V)

|

Weight

(KG)

|

Size (MM)

|

|

6NF-90

|

300

|

3~4

|

380

|

120

|

600x500x1200

|

|

NF-280

|

500

|

7.5

|

380

|

180

|

1000×400×1200

|

Burundi 50 tons corn flour production line

Ethiopia coffee beans cleaning line built by Win

Thailand mung bean peeling line installation

Ecuador 500 tons of corn flour production line

PACKING & SHIPPING

COMPANY INFORMATION

LUSHAN WIN TONE ENGINEERING TECHNOLOGY CO., LTD

Lushan Win Tone Engineering Technology Co., Ltd. (formerly known as Lushan Win Tone Machinery Manufacture Co., Ltd.) wasestablished in 1995. I t is a leading company integrated with research, manufacture and marketing of grain projects.

It has a modern manufacturing base,a precision casting factory, a research and development center for grain, oil and starch syrup processing lines and an international trade center, guaranteeing efficient technology as well as high quality and precision equipments. Win Tone hasISO9001:2008 international quality system certification and more than 20 new practical products patents.

Hot Searches