- Product Details

- {{item.text}}

Quick Details

-

Dimension(L*W*H):

-

custom made

-

Weight (T):

-

20 T

-

Power (kW):

-

48 to 480(depend on size)

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Oil tank Capacity:

-

800L to 14000L(depend on model)

-

Structure:

-

Horizontal Dual-chamber

-

Loading capacity:

-

200kg to 1200kg (adjustable)

-

Vacuum system:

-

Leybold, EVP, Edwards, Kinney

-

Heating method:

-

Resistance

-

PLC controller:

-

SIEMENS, MITSUBISHI, LG

-

Heater:

-

Mo belt, Tungsten, Graphite, SiMo, SiC

-

Max temperature:

-

1300℃ (custom made)

-

OEM service:

-

Acceptable

Quick Details

-

Place of Origin:

-

Shanghai, China

-

Brand Name:

-

SIMUWU

-

Voltage:

-

380V (adjustable)

-

Dimension(L*W*H):

-

custom made

-

Weight (T):

-

20 T

-

Power (kW):

-

48 to 480(depend on size)

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Oil tank Capacity:

-

800L to 14000L(depend on model)

-

Structure:

-

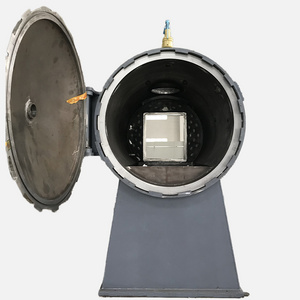

Horizontal Dual-chamber

-

Loading capacity:

-

200kg to 1200kg (adjustable)

-

Vacuum system:

-

Leybold, EVP, Edwards, Kinney

-

Heating method:

-

Resistance

-

PLC controller:

-

SIEMENS, MITSUBISHI, LG

-

Heater:

-

Mo belt, Tungsten, Graphite, SiMo, SiC

-

Max temperature:

-

1300℃ (custom made)

-

OEM service:

-

Acceptable

Metallurgy powder industry vacuum furnace

The main process of oil quenching is to heat the workpiece in the vacuum chamber, move it to the vacuum cooling chamber, then fill it with high-purity nitrogen and immediately send it into the quenching oil tank. There is a stirrer in the oil tank, which can be quickly stirred and cooled. Through oil quenching, a workpiece with good microstructure and no surface oxidation and decarburization can be obtained. The oil quenching cooling speed is fast, the workpiece deformation is small, which is widely used in mold steel heat treatment.

Click here to inquiry engineer for details !

More furnace as below for your choice!

|

FURNACE NAME |

Model |

Application |

Decription |

|

Vacuum Heat Treatment Furnace |

(1) RVGQ-series Gas Quencing (2) VOGQ-series Oil Quencing (3) RVA-series Annealing (4) RVT-series Tempering (5) RVC-series Vacuum Carburzing (6) RVN-series Nitriding (7) RVN-T-series PIT Gas Nitriding (8) GH-GCF-series Gas Carburzing |

Mould steel High speed steel. H13 HSS D2 Inconel Stainless steel Other material |

Max Temp:1350 ℃ Temp Uniformity: ± 3 ℃ or ± 5 ℃ Ultimate vaccum:6.67x10-3Pa(custom made) Gas pressure:6/10/15/20Bar |

|

Vacuum Sintering Furnace |

(1) RVS-series Sintering Furnace (2) IVS-H Induction Sintering (3) CDF-series Catalytic debinding (4) RVS-S-Series SIC Sintering (5) RVS-D-series Debinding&Sintering |

MIM parts PM parts CIM parts Silicone carbide SIC B4C NdFeB Titanium Tungsten carbide Other material |

Max Temp:1200-2400 ℃ Temp Uniformity: ± 3 ℃ or ± 5 ℃ Ultimate vaccum:6.67x10-3Pa (custom made) Gas : Ar/N2/H2(Optional) |

|

Vacuum Brazing Furnace |

(1)RVB-series Low temperature brazing (2)RHVB-series High temperature brazing (3)RVB-AL aluminum brazing |

Glass brazing Bar-plate, tube fin aluminum heat exchanger Stainless steel Copper PCD,PCBN,CVD Other material |

Max Temp:850-1300 ℃ Temp Uniformity: ± 3 ℃ or ± 5 ℃ Ultimate vaccum:6.67x10-3Pa (custom made) Gas : Ar/N2/H2(Optional) |

|

Vacuum Induction Melting Furnace |

(1)IVM-series Induction Melting (2)IVM-C-series Continuous Induction Melting |

Stainless steel Nickel alloy Cooper Other material |

Max Temp:1850 ℃ Ultimate vaccum:6.67x10-3Pa (custom made) Capacity:10kg-1Ton |

|

Non-Standard Vacuum Equipment |

Custom made |

More materials |

Custom made according to your requirement |

Click here to inquiry engineer for details !

Click here to inquiry engineer for details !