- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

GFK

-

Model Number:

-

VP70

-

Voltage:

-

380V

-

Power:

-

upper90kw lower250+15*2

-

Dimension(L*W*H):

-

7300*2500*2500

-

Warranty:

-

1 year

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

technoligy:

-

German

-

trademark:

-

GFK

-

Painting:

-

Wear Resistant Spray Painting

-

Brick Plant Type:

-

Automatic Clay Brick Plant

-

Material:

-

clay,coal,flyash,gangue,etc

-

body of extruder:

-

Full-steel

-

Vacuum Degree:

-

≤-0.092Mpa

-

Kiln Type:

-

Tunnel Kiln/Hoffman Kiln

-

Steel Proceed:

-

Quenching & Tempering

-

Colour:

-

according to customer's requirements

-

Certification:

-

ISO9001:2008

Quick Details

-

Type:

-

solid and hollow bricks

-

Brick Raw Material:

-

Clay

-

Production Capacity (Pieces/8 hours):

-

15000-21000pcs/hour

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

GFK

-

Model Number:

-

VP70

-

Voltage:

-

380V

-

Power:

-

upper90kw lower250+15*2

-

Dimension(L*W*H):

-

7300*2500*2500

-

Warranty:

-

1 year

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

technoligy:

-

German

-

trademark:

-

GFK

-

Painting:

-

Wear Resistant Spray Painting

-

Brick Plant Type:

-

Automatic Clay Brick Plant

-

Material:

-

clay,coal,flyash,gangue,etc

-

body of extruder:

-

Full-steel

-

Vacuum Degree:

-

≤-0.092Mpa

-

Kiln Type:

-

Tunnel Kiln/Hoffman Kiln

-

Steel Proceed:

-

Quenching & Tempering

-

Colour:

-

according to customer's requirements

-

Certification:

-

ISO9001:2008

used pug mill for sale

1.Spare parts are free for you;

2.Larger service time;

3.Using German technology;

4.Save cost,save labour

German technology used pug mill for sale

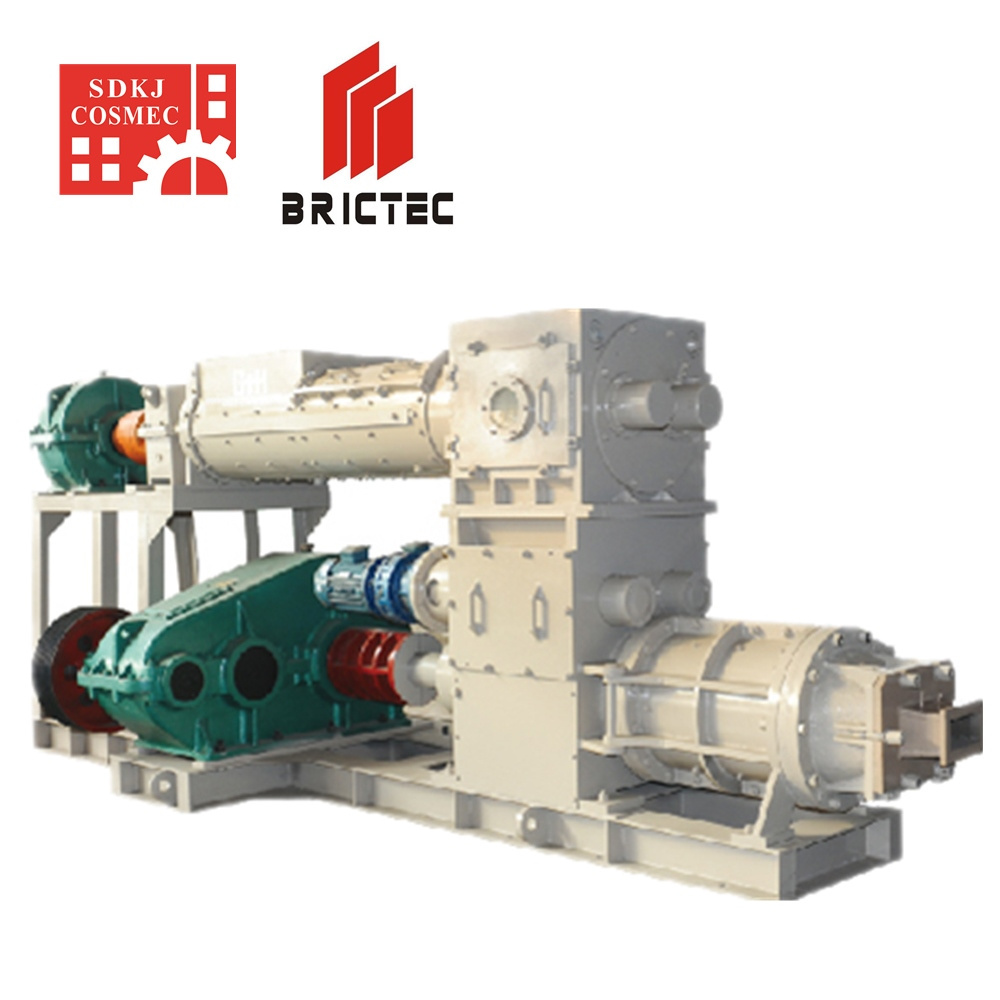

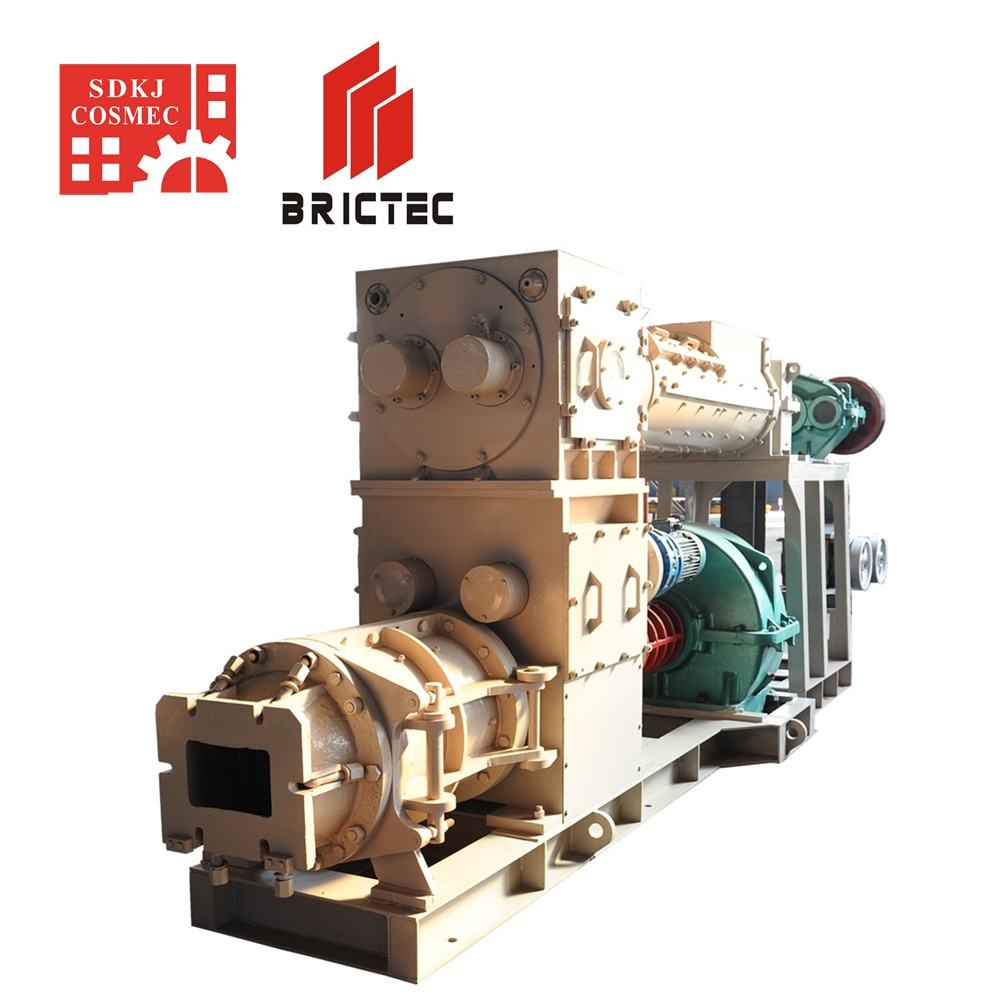

1.Vacuum extruder for brick machine applies to clay,shale,coal gangue,fly ash,split brick etc,to produce all kinds of hollow blocks and solid bricks and color paving bricks, only by changing different mouth-piece.

2. Extrusion pressure: 3.0MPa, it can make both solid and hollow brick and big holes

3. Main axle techniques: Quenching, tempering, the suppression experiment, so strengthen main axle's steel and toughness .

4. Reamer techniques : adopts the high chromium casting , passed the aging , quenching and tempering process

5. Techniques of squeeze out cylinder and vacuum chamber: the whole processing, quenching processing, these can increase the toughness and extent complete machine life.

6. T he steel material of shafts and gears adopt high quality carbon steel and alloy steel , the key parts are quenched and tempered treated so as to extend fly ash bricks making machine life .

7.For double shaft mixer blades, we choose 45 Carbon steel as material

8.Differ types of moulds insure that you can produce different types of brick( Solid and hollow brick )

| Model No | Capacity (pcs/gh) | Power(kw) | Extruding pressure(Mpa) | Vacuum pressure(Mpa) | Dim(mm) |

| VP45A | 10000-15000 | upper55 lower110+7.5*2 | ≤4 | ≤0.092 | 7300*2700*2500 |

| VP45B | 10000-15000 | upper55 lower110+7.5*2 | ≤3 | ≤0.092 | 7300*2700*2500 |

| VP50A | 12000-16000 | upper55 lower132+7.5*2 | ≤4 | ≤0.092 | 7300*2700*2500 |

| VP50B | 12000-16000 | upper55 lower132+7.5*2 | ≤3 | ≤0.092 | 7300*2700*2500 |

| VP70A | 15000-21000 | upper90 lower250+2*15 | ≤4 | ≤0.092 | 7000*2500*2500 |

| VP70A- Ⅱ | 20000-28000 | upper90 lower250+2*15 | ≤3 | ≤0.092 | 7590*2920*2885 |

| Notes | 3.5kg/pcs | (L.W.H) |

Note :if your brick size is different , then the capacity will differ .We would send different brick capacity list and different brick machine price list to you once we get your mail to us.

Raw materials and Brick sample photos

The extruder is the main parts of brick making plant and our extruder is suitable for producing all kinds of cell brick with material like clay, gangue, shale, fly ash .

The following is part of brick sample which auto brick making machine can produce .

Note: We can provide other different brick mould with different mould sizes according to your requirements

The whole set of machinery of clay brick production line

|

No. |

Machinery |

|

1 |

Box feeder |

|

2 |

Belt conveyor |

|

3 |

Primary roll crusher |

|

4 |

Belt conveyor |

|

5 |

Double shaft mixer |

|

6 |

Belt conveyor |

|

7 |

High speed roll crusher |

|

8 |

Belt conveyor |

|

9 |

Double shaft mixer |

|

10 |

Belt conveyor |

|

11 |

Double stage de-airing extruder |

|

12 |

Vacuum pump |

|

13 |

Air compressor |

|

14 |

Auto brick cutting system |

|

15 |

Belt conveyor (waste brick return to mixer) |

|

16 |

Control panels |

|

17 |

V Belt |

|

18 |

Spare parts |

|

19 |

dryer |

|

20 |

kiln |

Clay brick production line

Note: The above production line is based on clay,shale,coal gangue,fly ash or with small stones .And this is full automatic,if you want to save money , you can`t use robotic and setting machine,you can manual setting,but waste time and expend is very high.the automatic is suitable for tunnel kiln,and manual is Hoffman kiln.

Major equipments in clay brick production line.

1.Box Feeder

This machine is used for constant feeding of raw material before grinding

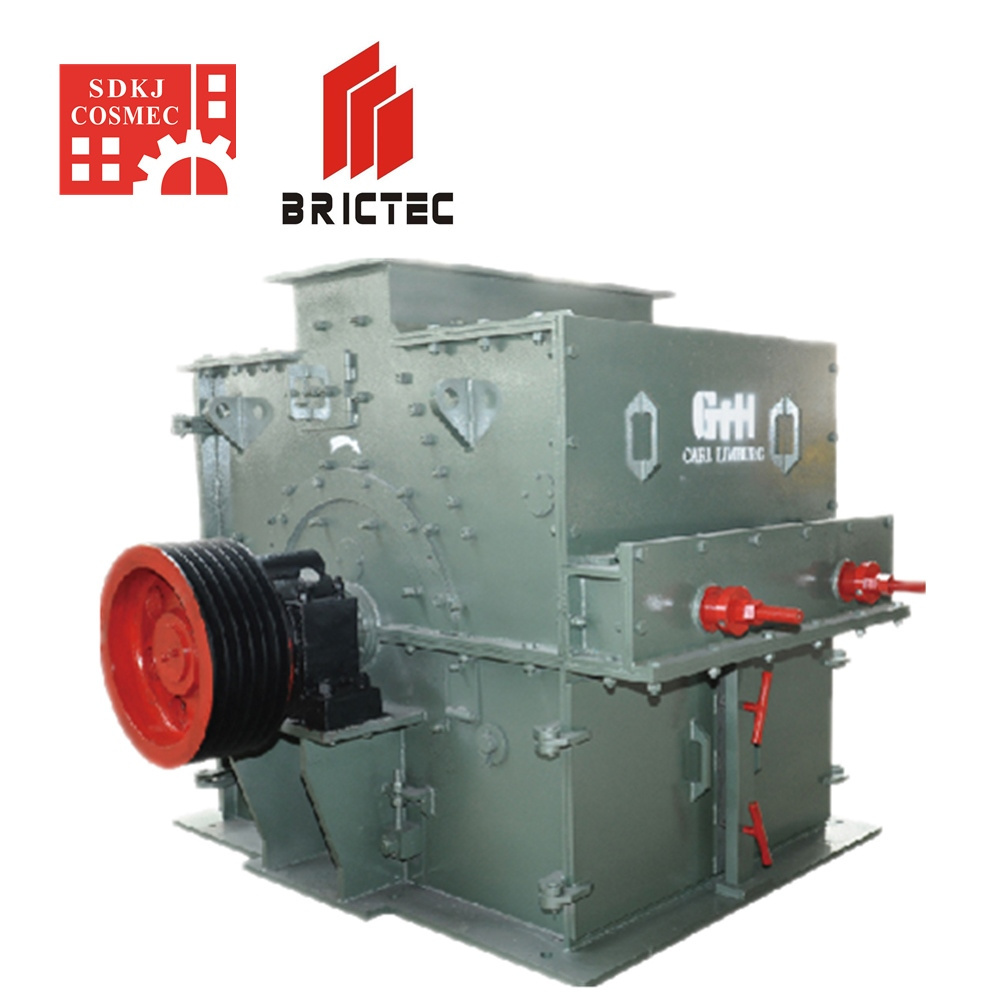

2.Crusher

This machine is used for crushing the raw material.

3.Mixer

This machine is used for mixing the raw material and the water.

4. Brick making machine

It is used for making the green brick strips.

5.Cutter

It is used for cutting the adobe strip into the green brick according to different size requirement

| After brick cutting how to do brick drying and firing | |||||||||||

| Item | Drying method | Firing method | Advantage and disadvantage | ||||||||

| 1 | Natural drying | Buyer Local kiln | Very low investment, but may take more labors | ||||||||

| 2 | Natural drying | Hoffman kiln | A little high investment, but may take more labors | ||||||||

| 3 | Natural drying | Tunnel kiln | High investment, but takes less labors than Item 2 | ||||||||

| 4 | Small tunnel dryer | Hoffman kiln | High investment, but takes less labors than Item 2 | ||||||||

| 5 | Small tunnel dryer | Tunnel kiln | Higher investment, but takes less labors than Item 4 | ||||||||

| 6 | Big Tunnel dryer | Tunnel kiln | Highest investment, but takes least labors | ||||||||

1.Each small part of machine would be packed well, also we would arrange engineer to check each machine parts before delivery, so we can ensure buyer can get complete brick making machine for clay parts. .

2. Some parts will be given soft protection before feeding in the container to make sure all the machine will

be new when arriving at customer hand.

3. Inside the container, we will fix the machine with steel wire,to make sure all the machine will be fixed safety.

Before sale

(1) tell customer how to build a brick plant, the complete plant including three parts, brick shaping machinery, drying and firing.(Confirm clay,power electricity,water,land area, fund)

(2) Guide customers to choose the best and economic plant, recover the investment within short time.

(3) site inspection

(4) We are responsible for the offer, flow chart, and detail specification of each machinery

In sale:

(1)Quality control must be inspected strictly

(2)In accordance with the agreements stipulated in the contract

After sale:

(1) We will send the technicians to guide with device installation, debugging and training operators until customers are fully satisfied.

(2) Guarantee for machinery, materials and equipment supplied under this quotation are valid for a period of 12 months after commissioning or 16 months after delivery whichever is earlier. Warranty shall cover manufacturing defect in material and workmanship but exclude:

1. Daily wear and tear

2.mishandling or improper operation

3. Incoming power supply fluctuation

4. Consumable and spare parts.

(3) Regular visit customer, consult with the customer feedback, come true with the customer's two-way communication

Note: Warmly welcome domestic and foreign friends to visit our company for negotiation