- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

220V

-

Dimensions:

-

78*68*55CM

-

Rated Duty Cycle:

-

100%

-

Rated Capacity:

-

1.2KW

-

Current:

-

50/60Mhz

-

Weight (KG):

-

54 KG

-

After-sales Service Provided:

-

Engineers available to service machinery overseas, Video technical support, Online support

-

Effective working table area:

-

360mm * 230mm (more than A4)

-

Heating supply:

-

Infrared ray + Hot air convection

-

Welding time:

-

3min ± 1min

-

Warm-up time:

-

3min

-

Temperature control segment:

-

40 segments

-

Name:

-

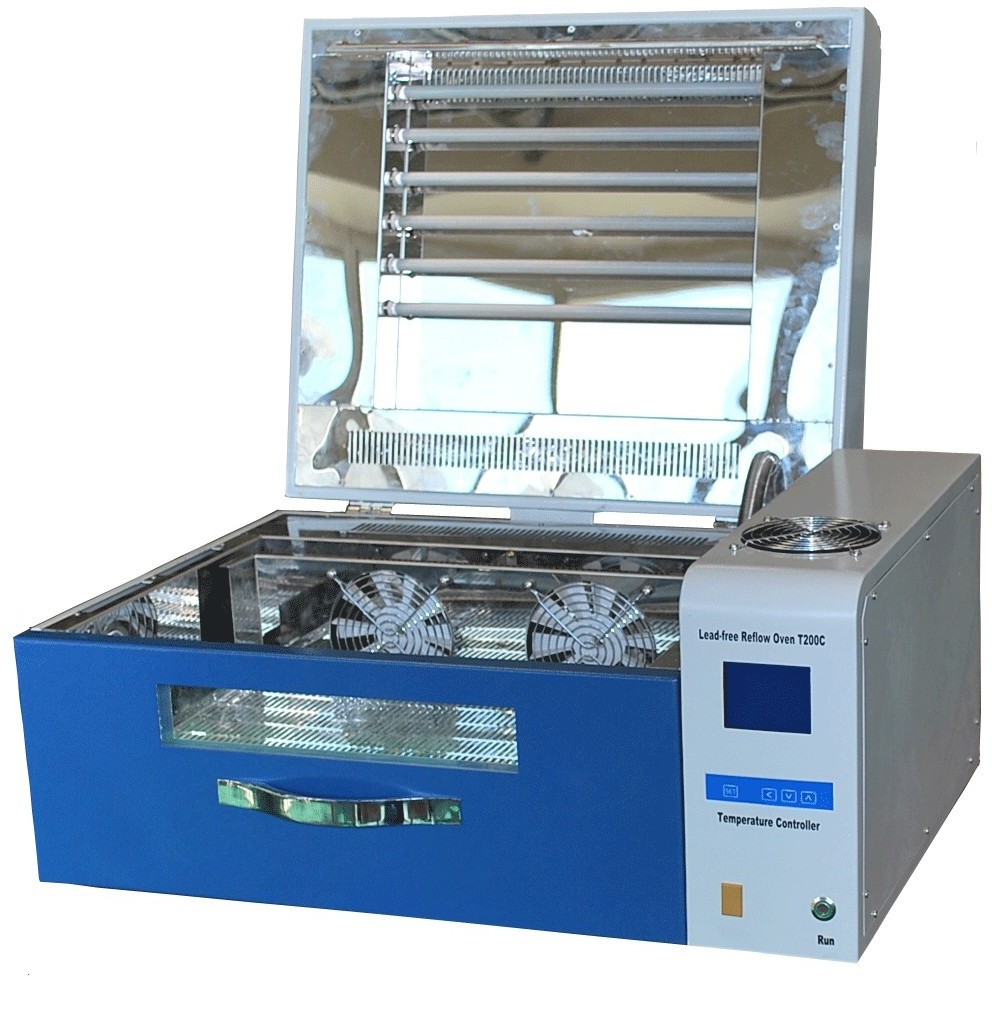

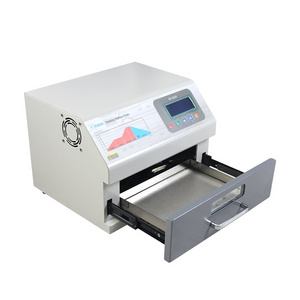

Small Infrared SMT/SND reflow oven T200C+/T200C computer reflow oven

-

Function:

-

Welding Solder Paste

-

After Warranty Service:

-

Video technical support, Online support

-

Local Service Location:

-

Germany

-

Certification:

-

ISO CE

Quick Details

-

Place of Origin:

-

Beijing, China

-

Brand Name:

-

TORCH

-

Use:

-

reflow oven or repair PCB

-

Voltage:

-

220V

-

Dimensions:

-

78*68*55CM

-

Rated Duty Cycle:

-

100%

-

Rated Capacity:

-

1.2KW

-

Current:

-

50/60Mhz

-

Weight (KG):

-

54 KG

-

After-sales Service Provided:

-

Engineers available to service machinery overseas, Video technical support, Online support

-

Effective working table area:

-

360mm * 230mm (more than A4)

-

Heating supply:

-

Infrared ray + Hot air convection

-

Welding time:

-

3min ± 1min

-

Warm-up time:

-

3min

-

Temperature control segment:

-

40 segments

-

Name:

-

Small Infrared SMT/SND reflow oven T200C+/T200C computer reflow oven

-

Function:

-

Welding Solder Paste

-

After Warranty Service:

-

Video technical support, Online support

-

Local Service Location:

-

Germany

-

Certification:

-

ISO CE

Torch Small Infrared SMT 40 Segments Controlled Reflow Oven T200C+/T200C

Honor customer :

TORCH brand desktop reflow oven has got purchse order from TOP 500 enterprises: GE, CISCO, 3M, TI, NVIDIA, Nortel Network ect last year, especially GE and CISCO, totally purchased for more than 12 sets.

T200A is manufactured by Torch in 2001, which is the first desk lead free reflow oven.

As an epoch-making product, T200C break instrument controlling market in 2005. In last 4 years, T200C entered General Electric (U.S.), Sony (Japan), the NVIDA (United States), Chinese Academy of Sciences of the semiconductor, aerospace electronics, BYD and other well-known enterprises and laboratories.

Torch develops and manufactures new products T200C+ according to requirement and need from domestic and foreign market. T200C+ is suitable to small batch products, it is the good choice for electronics enterprises and research institutes, at the same time it is the complementary equipment for large and medium-sized production line.

T200C+ unique features

1. With all advantage of T200C

2. With better airproof function, the temperature is more uniformity.

3. With emitting smoke function.

4. With purifying and filtering exhaust gas function.

5. With single channel temperature measurement (multi channels is optical), T200C+ has been the first-class reflow oven.

high precision, multi function;

40 segment temperature curves can be set. It satisfies the welding of different components.

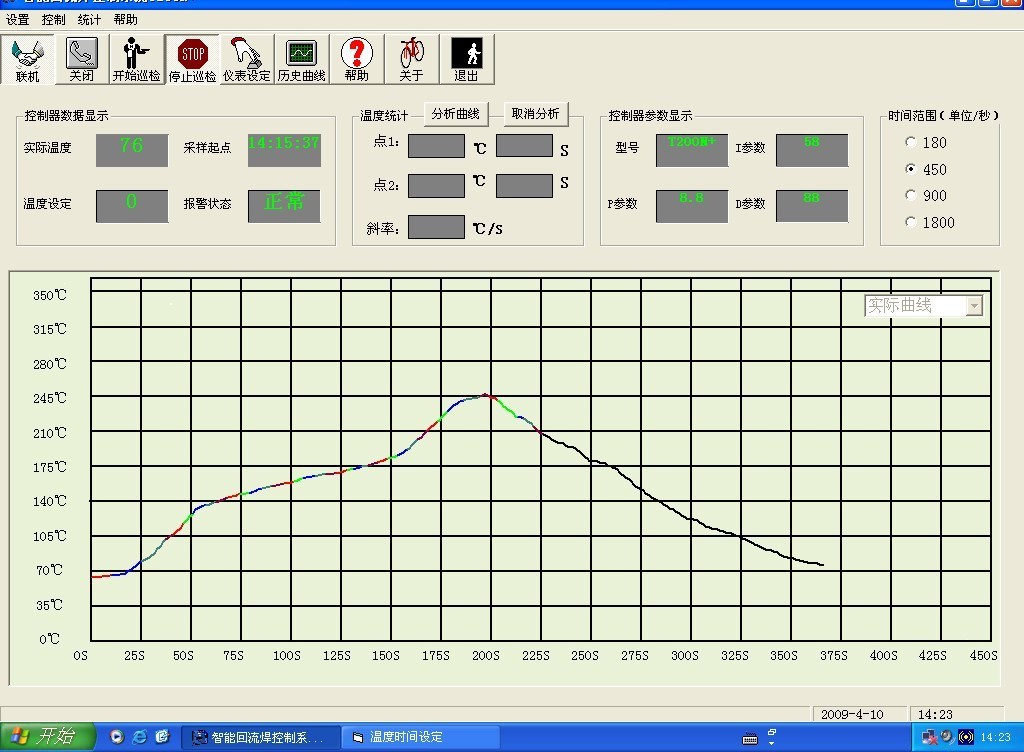

computer control

T200C+ breaks through the shortages such as the difficulty of meter control program, the difficulty of modify parameter, limited storage of temperature curve. It adopts the software for temperature control, which is produced by Torch itself. The temperature curve can be set intuitively. And a large number of temperature curves can be stored. Analysis and statistics function, printing function.

Real time testing with temperature curve

Test the temperature curve of soldering at every time. During the process of welding, the actual temperature can be displayed at the same time. It is convenient to adjust and control the lead-free curve. Especially control the heat preservation zone and the melting zone.

Viewable operation

The real time display of temperature and the real time observation of the welding process. It is the best choice for science research and teaching.

T200C+ technology parameters

:

|

Item |

Parameter |

|

Temperature control segment |

40 segment .The segment can be set in computer according to the actual requirement. |

|

Temperature-zone numbers |

Single-zone and multi-segment |

|

Temperature control system |

PC control system ,SSR non-contact output. |

|

Temperature accuracy |

±2 ℃ |

|

Warm-up time |

3min |

|

Temperature range |

Room-temperature -360 ℃ |

|

Heating supply |

Infrared ray + Hot air convection |

|

Effective working table area |

360mm * 230mm (less than A4) |

|

Welding time |

3min±1min |

|

Temperature curve |

It can be set ,adjusted and tested according to the actual requirement . |

|

Cooling system |

Transverse flow equal cooling |

|

Rated voltage |

AC single-phase ,220V;50Hz |

|

Rated power |

3.8KW |

|

Mean power |

1.6kw |

|

Weight |

39kg |

|

Dimension |

Length*width*height 700*460*310mm |