Packing Details : Packing, solid bicycle saddle, 50pcs/carton

Delivery Details : 3-30 days after order of Solid bicycle tire tubes

- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

QiiMii

-

Liquid Flow Rate:

-

1.5 T/H

-

Weight:

-

63-200kg

-

Dimension(L*W*H):

-

160*500*0.5

-

Working Temperature Range:

-

-10℃ - +150℃

-

Product Name:

-

Heat Exchanger

-

Application:

-

Beer, Milk, etc

-

Plate Material:

-

304

-

Body material:

-

304

-

Gasket material:

-

NBR, EPDM

-

Cooling:

-

Single Stage Or Two Stages

-

Plate Number:

-

51

-

Packing:

-

Ply-wooden

-

AREA:

-

3 M2

Quick Details

-

Structure:

-

Plate Heat Exchanger

-

Core Components:

-

Plate Heat Exchanger

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

QiiMii

-

Liquid Flow Rate:

-

1.5 T/H

-

Weight:

-

63-200kg

-

Dimension(L*W*H):

-

160*500*0.5

-

Working Temperature Range:

-

-10℃ - +150℃

-

Product Name:

-

Heat Exchanger

-

Application:

-

Beer, Milk, etc

-

Plate Material:

-

304

-

Body material:

-

304

-

Gasket material:

-

NBR, EPDM

-

Cooling:

-

Single Stage Or Two Stages

-

Plate Number:

-

51

-

Packing:

-

Ply-wooden

-

AREA:

-

3 M2

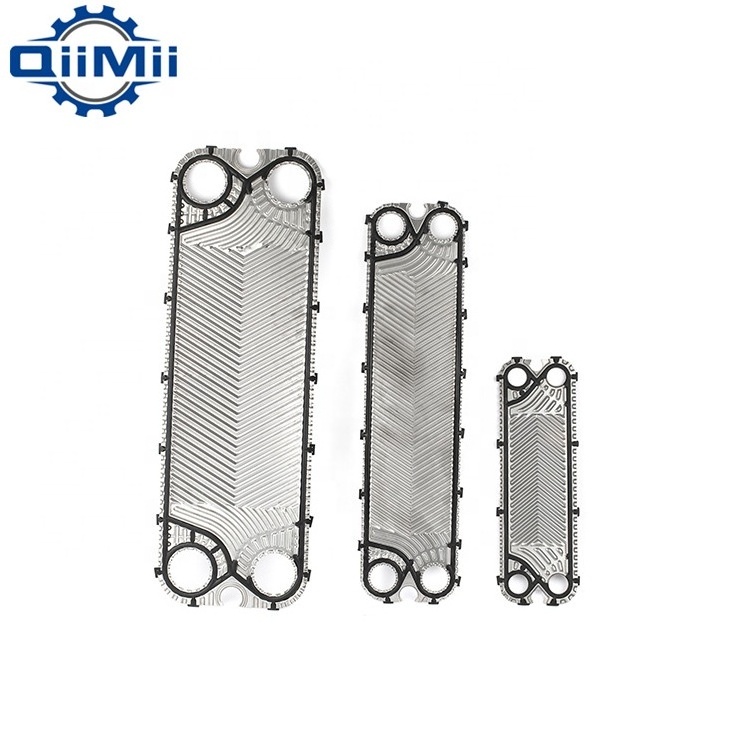

Product Description

|

Product Name:

|

Plate Heat Exchanger

|

|

Plate Material:

|

304 or 316L

|

|

Body Material:

|

304

|

|

Gasket Material:

|

NBR, EPDM, etc

|

|

Max Working Pressure:

|

3Mpa

|

|

Working temperature:

|

-10℃ - +150℃

|

|

Cooling:

|

Single stage or two stages

|

|

Size:

|

1m², 3m², 5m², 7m², 10m²

|

|

Plate Number:

|

17 - 77

|

|

Packing Details:

|

Usually Plywood case for each plate heat exchanger for directly shipping. Extra

wooden case is availabe when necessary |

|

Model Number

|

Plate Size

(length*width*height)

|

Channel

|

Heat Exchange Area

(M²)

|

Flow

(T/H)

|

Plate Quantity

|

Connect Size

|

|

PHE-0.06

|

160*500*0.5

|

Single Channel

|

1

|

0.5

|

17

|

32mm

|

|

PHE-0.06

|

160*500*0.5

|

Double Channel

|

3

|

1.5

|

20+31

|

32mm

|

|

PHE-0.13

|

200*800*0.4

|

Double Channel

|

5

|

2.5

|

15+24

|

38mm

|

|

PHE-0.13

|

200*800*0.4

|

Double Channel

|

7

|

3

|

22+33

|

38mm

|

|

PHE-0.13

|

200*800*0.4

|

Double Channel

|

10

|

5

|

31+46

|

38mm

|

Working principle

The plate type heat exchanger is composed of a group of corrugated metal plants. The holes on it form channel for liquids to flow, and the heat will be transferred between two kinds of liquids.

The plates are assembled between a fixed frame board and a moveable clamping board and are tightened by the tightening bolts.

These plates are installed with sealing gaskets. The sealing gaskets play the sealing function on the channels between plates and make the liquids flow into adjacent channels.The quantity of plates are determined by flow, physical properties and temperature of liquids. The joints can be located on the frame board and clamping board.

Standard materials

The frame and clamping board can be subjected to painting on the surface or coated by stainless steel.The moving nuts on the fastening bolts are made of A3.

Plate type

BR-0.06,0.12,0.2,0.3,0.45,0.65 plate stainless steel AISI,316L,316,304

Sealing gasket type

NBRor EPDM,Q

Technical date

Mechanical designed pressure/temperature

Designed pressure l.OMpa

Working pressure 0.6Mpa

Working temperature -10°C -+150°C

Joint type

DIN,SMS,ISO,male thread or others can be supplied according to requirements.

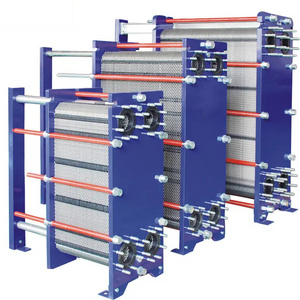

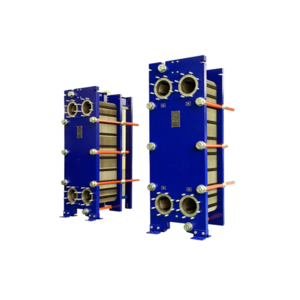

Products Show

Flow chart

Application

Pasteurization

Normal cooling and heating in such industries as dairy, brewage, beverage, food, etc.

Heating and cooling in pharmaceutical industry.

Flow Combination

The plate type heat exchanger is provided with various flow combination types,which are all realized by adopting different reversal plates and different assembling methods.The flow combination is divided into single flow,multiple flow and mixed flow,which shall be selected according to the technological requirements .Generally,the medium with its temperature difference higher than 1.8 times the logarithmic average temperature difference should adopt he multiple flow .with an inter-plate flow rate of 0.3-0.5M/S; if the flow rate is too low.the double flow or multiple flow should be applied.

Mixed connection flow combination figure

Parallel connection flow combination figure

Recommend Products

Our Service

Our Company

Our Certifications

Quality is our corporate culture

QM stainless has been audited and certified as meeting the full requirements of ISO 9001, CE, FDA, including design, manufacture, inspection, customer service, and distribution functions.

Exhibition show

FAQ

Q: Why would I choose you?

Wenzhou QiMing Stainless Co., Ltd has been engaging in manufacturing sanitary valves, fittings, tank components and pumps for over 15 years, outstanding in production capacity, effective management, accurate lead time, on-time shipments and problems-solvingrate after sales.

Q: May I have free samples before ordering?

Yes, our company is very pleased to send you free samples for quality test as long as freight cost being paid by buyers themselves.

Q: What’s the MOQ?

The majority of products are fully in stock, so we accept 1 piece as the minimum order quantity.

Q: Does your company have the export license?

Yes, we have more than 4 years export experience, we can do FOB, C&F, CIF, DDU and DDP (Russian Only).

Q: What’s the payment term?

For small testing orders, we accept Paypal, Western Union, T/T and Credit Card.

For mass orders, we accept T/T and L/C.

Q: How would you minimize damages during delivery?

Standard: mass orders will be packed by many carbon boxes and filled in plywood cases.

Available requirement: blister packing for every piece of product, plastic caps for clamp connected products.

Q: How would you choose the shipment way?

Basically, we will select shipment ways based on four factors (order quantity, delivery time, costs and customs policy), then listcouples of reasonable options with Pros and Cons to customers, letting them to decide.

Wenzhou QiMing Stainless Co., Ltd has been engaging in manufacturing sanitary valves, fittings, tank components and pumps for over 15 years, outstanding in production capacity, effective management, accurate lead time, on-time shipments and problems-solvingrate after sales.

Q: May I have free samples before ordering?

Yes, our company is very pleased to send you free samples for quality test as long as freight cost being paid by buyers themselves.

Q: What’s the MOQ?

The majority of products are fully in stock, so we accept 1 piece as the minimum order quantity.

Q: Does your company have the export license?

Yes, we have more than 4 years export experience, we can do FOB, C&F, CIF, DDU and DDP (Russian Only).

Q: What’s the payment term?

For small testing orders, we accept Paypal, Western Union, T/T and Credit Card.

For mass orders, we accept T/T and L/C.

Q: How would you minimize damages during delivery?

Standard: mass orders will be packed by many carbon boxes and filled in plywood cases.

Available requirement: blister packing for every piece of product, plastic caps for clamp connected products.

Q: How would you choose the shipment way?

Basically, we will select shipment ways based on four factors (order quantity, delivery time, costs and customs policy), then listcouples of reasonable options with Pros and Cons to customers, letting them to decide.

Hot Searches