- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

380V

-

Power:

-

OEM

-

Weight:

-

1500 KG

-

Dimension(L*W*H):

-

OEM

-

Product name:

-

Canned Wet Pet Food Production Line

-

Function:

-

Cleaning

-

Material:

-

304 Stainless Steel

-

Advantage:

-

Efficent

-

Feature:

-

High Capacity

-

Capacity:

-

1000kg/h

-

Related machine:

-

Filling

-

Used for:

-

Pet canned food packing

Quick Details

-

Marketing Type:

-

New Product 2023

-

Place of Origin:

-

Shanghai, China

-

Brand Name:

-

LWT

-

Voltage:

-

380V

-

Power:

-

OEM

-

Weight:

-

1500 KG

-

Dimension(L*W*H):

-

OEM

-

Product name:

-

Canned Wet Pet Food Production Line

-

Function:

-

Cleaning

-

Material:

-

304 Stainless Steel

-

Advantage:

-

Efficent

-

Feature:

-

High Capacity

-

Capacity:

-

1000kg/h

-

Related machine:

-

Filling

-

Used for:

-

Pet canned food packing

Product Description

Automatic Pet Food Packing Machines Cat Food Canned Machines

Pet Food Production Line

|

Name

|

|

|

1. Tin cans feeding turntable

|

|

|

2. Option of empty tin cans washing machine

|

|

|

2. Filling machine

|

|

|

3.Exhausting machine

|

|

|

4.Cans sealing machine

|

|

Specification

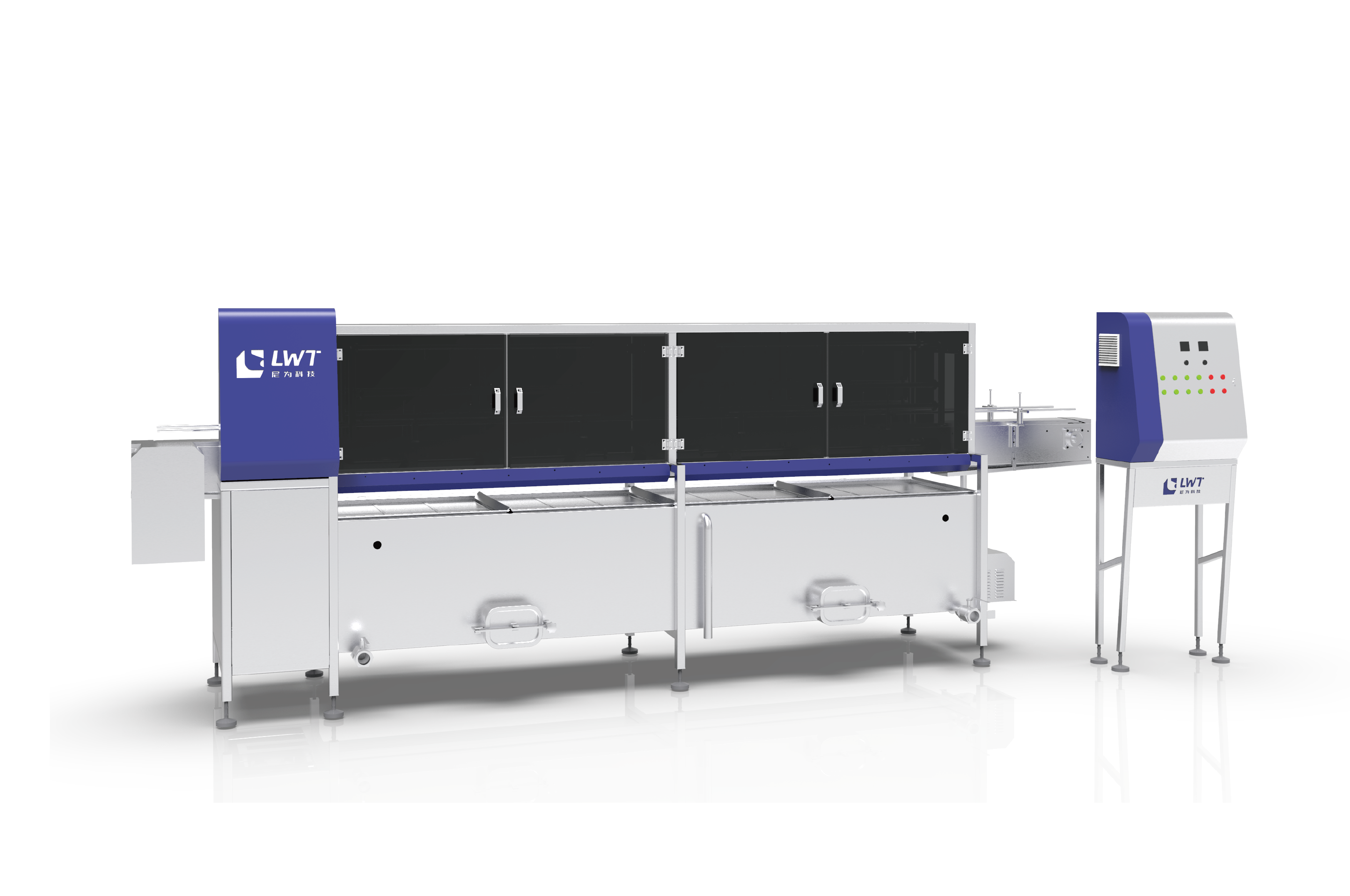

Empty tin cans washing machine

It is applied to clean inside surface of all kinds of canned fruit,canned meat,bottled sauce and all kinds of drinks,applying for tin cans,glass bottles and plastic bottles.

Machine features:

The whole machine adopts SUS304 stainless steel manufacturing,reduce pollution,ensuring healthyof the products.

High degree of automation, automatic tempreture control, good finish washing.

Using Acrylic hood, the whole cleaning process can be seen.

Double cleaning design, washing water can be recycled.

Advanced machine design structure,easy to clean,water tank large diameter drain hole.

Parameters:

Capacity:20-60cans/min,stepless speed.

Pipeline speed: 6-30m/min

Scope of application: Cans Dia 40-180mm,height40-200mm customize

Motor: 0.75kw, 10-50 r/min

Sanitary pump:0.75kw*2 12.5T/h

Pet Food Auto Filling Machine

Features:

1. Vacuum Preventing Leaking System

2. No Bottle or Lack of Bottle, No Filling System

3. Photoelectric Sensor, Mechatronics Filling Adjustment System

4. Photoelectric Sensor, Material Level Control Feeding System

5. Stainless Steel Frame, Plexiglass as Security Cover

6. Control System: PLC/Electronic-Pneumatic Controlled

7. Operation Panel: "Intelligent" Colorful Touch Screen

8. Filling Accuracy:+-0.5%-1%

9. Capacity Adjustment:All cylinders adjusted automatically combine single cylinder adjusted individually.

10.Container transport:Stainless steel frame and engineering plastic plate chain variable speed conveyor, with photoelectric sensor.

Exhausting machine

Equipment technical parameters:

Power: 380V / 50Hz, can customize

Degassing temperature: 85-98 ℃ adjustable;

Degassing time: 10-25 minutes adjustable;

Fuselage bracket: 80 * 40 stainless steel square tube welding;

Conveying carrier: stainless steel chain plate with flat surface, wear-resistant, high temperature-resistant, safe and fast;

Reducer: Taiwan Chengbang gear reduction motor;

Power: 0.75KW;

Cans sealing machine

Parameters:

Capacity:30-40cans/min

Cans diameter:less than 99mm

Cans height: 50-350mm

Power: 2.2kw

Motor speed:1400r/min

Machine size:1210*1690*1976mm

Weight:1380kg

Hot Searches