- Product Details

- {{item.text}}

Quick Details

-

Year:

-

2022

-

Weight (KG):

-

700

-

Certification:

-

ce

-

After-sales Service Provided:

-

Online,Video support

Quick Details

-

Place of Origin:

-

Tianjin, China

-

Brand Name:

-

EJON

-

Marketing Type:

-

New Product 2022

-

Year:

-

2022

-

Weight (KG):

-

700

-

Certification:

-

ce

-

After-sales Service Provided:

-

Online,Video support

Overview

Details

Place of Origin :Tianjin,china Brand Name:EJON

Conditon :New Model Type: ET20 Suitable Material : Stainless steel,Galvanized plate,Aluminum plate and profile Automaic :Automatic

After-Sales Service:Video/Oline support,Engineers Service Power :CNC

Slotting Method : Plane cutter and Milling wheel cutter slotting Trip:10-200mm

Bending Method : Double Tools Alternate Bending System Warranty of core:1 Year

Certification: CE Machine weight:700kg

Supply Ability

Supply Ability:8800 Sets/Year

Packing &Delivery

P ackaging Details:The Export Non-Fumigation Wooden Box

Port :Tianjin Port Or other China Port

Delivery Time : 10-20 Working Days

Product Description

EJ0N ET20 machine are multifuction automatic bending machine,it is widely used in Seiko letter,Resin letter,Brimless letter,Edged Aluminum letter and other letters.Suitable material include Stainless steel,Galvanized plate,Aluminum plate and Aluminum profile.

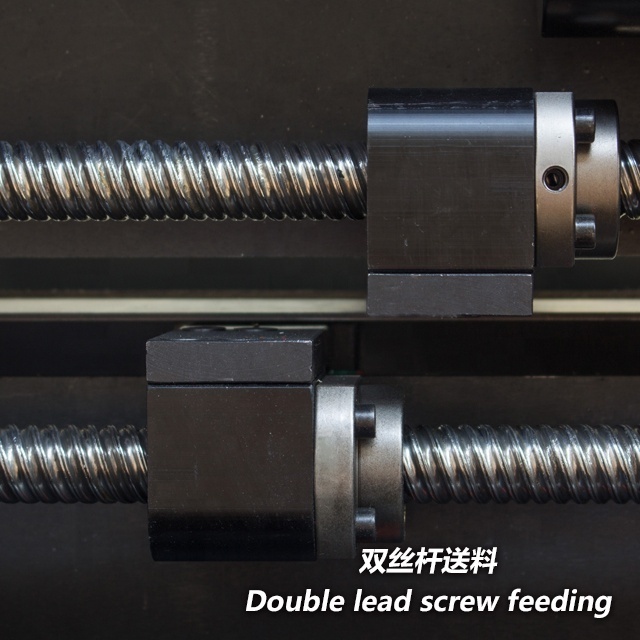

Manipulator alternately feeding structure,t he material clamps are casted which can avoid scratching the material,meanwhile improving the feeding holding.Using air pressure to press the material,avoid material uneven and ensure the smooth feeding.The double ball screw is matched with nylon gear transmission for precise positioning,which greatly improves the feeding speed and stability of the machine.

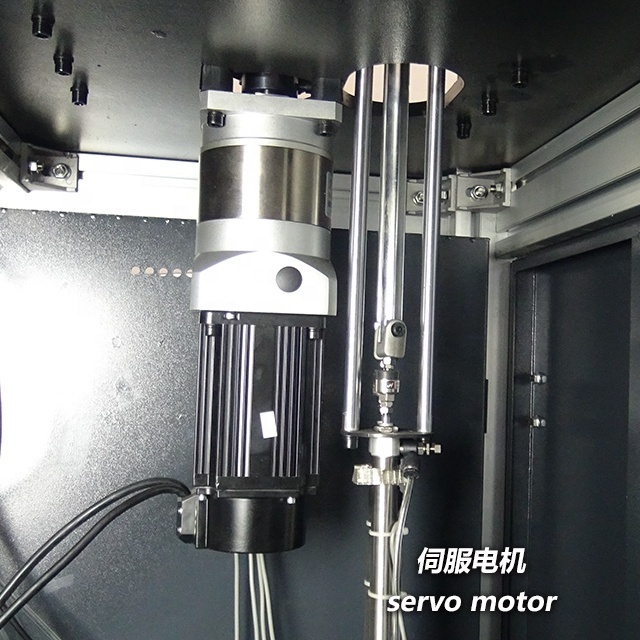

Plane cutter can slot all kinds of materials.The linear guideway is matched with the ball screw,with 750W high-power servo motor,greatly improve the feeding speed and stability.

High strength alloy cutters are used for slotting knifes.,each knife has 8 angles,no need to sharpen,greatly improve the working life.

Double-knife alternate bending structure,the curved knife structure cast by ductile iron ,good shock absorption,high structural strength,reduced number of parts splicing,high-power servo motor,high-speed bending work under the bending mechanism,the bending mechanism is permanently deformed,which effectively improves the positioning accuracy and the stability of the high-speed bending.

| SPECIFICATION | |

| SYSTEM | 7 Axis control system( 3 servo axis control ) |

| Feeding System | Circulation-typed clamp feeding system |

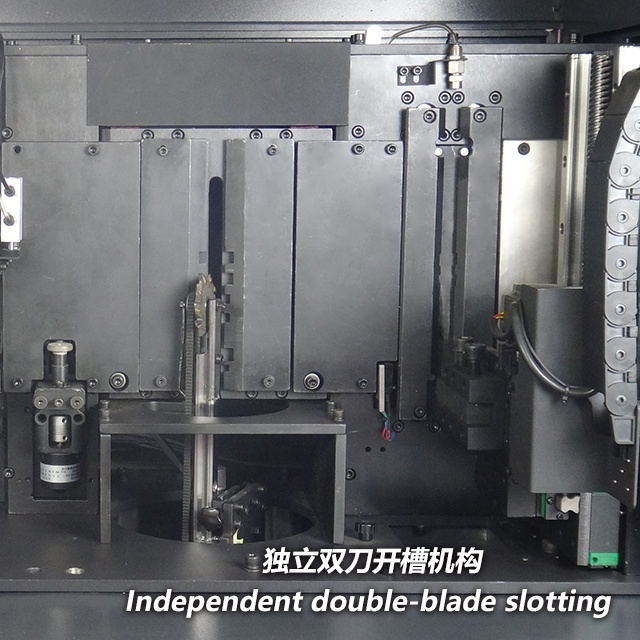

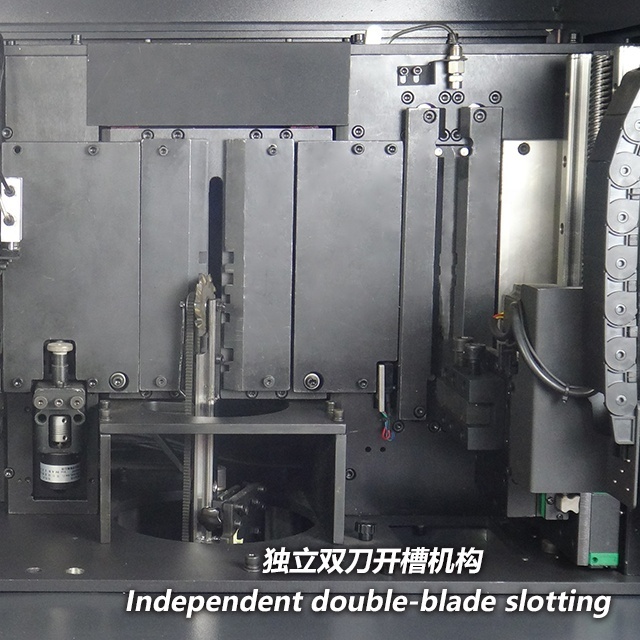

| Slotting System | Independent double-blade : Plane cutter slotting&milling wheel cutter slotting system |

| Bending System | Double blade alternate bending system |

| Suitable Material | Stainless steel,Galvanized plate,Aluminum plate and Aluminum profile |

| Slotting Height | 10-200mm |

| Material Thickness | 0.4-1.2mm |

| Control System | 7 Axis control system (3 servo axis control) |

| Min Bending Angle | R6 |

| File Format | Dxf.Plt.Ai |

| Power | AC220V,50HZ,2.0KW |

| Air Supply | 0.6m3/min |

| Package Size | 1410*780*1600mm |

| Working Space | 2400*1100*1500mm |

| Machine Weight | 700Kg |

ET20 Machine part details

Feeding Parts :T he feeding structure adopts double ball

screw matched with nylon gear transmission ensuring

the precise positioning,smooth feeding,greatly improving

the feeding speed and stability.

Slotting Parts: Independent double-blade slotting . The

slotting mechanism adds a new air blowing and cooling function

to extend the service life of the cutter while ensuring smooth

slotting.

Bending Parts : Double blade alternate bending system,the bending adopts servo motor ,high torque,high forming

degree.

Sample Showing

How to learn machine operate

1. Operation Manual U disk

Provide U disk with machine which have detail specific english operational manual and videos.

2. Network Service

Through Wechat,Whatsapp,Skype,E-mail,Team viewer provide online service.

3. Factory Visiting

Welcome customer to visit our factory to learn how to operate the machine.

Supporting Facility

Computer Pump File Format

To use the device,you need to The use of equipment should The software of bending

install the control card in your be equipped with machine is self-developed. computer and then connect to AIR compressor, we suggest Import the format supports

the bending machine and install that the selection of more Dxf.Plt.Ai .We recommend

the software computer. than 4kw ,the gas flow is using C oredraw or adobe

Configuration: XP system or 0.6m3/Min illustrator to complete

window7 32-bit system,and the file after the export file

requires a pcl card slot to to Dxf.Plt.Ai format.Then

install the control card. open the operating software,

select the document

EXhibition

Our company

Certification

CONTACT WAYS

Wechat: 8613780384902/8613194633004

Phone: 8613780384902/8613194633004

Whatspp: 8613780384902

E-mail: stevenzhao2007 at tj-ejon.com

Skype: 8613780384902

QQ:122085687