- Product Details

- {{item.text}}

Quick Details

-

EINECS No.:

-

426-580-9

-

Place of Origin:

-

Anhui, China

-

Brand Name:

-

Low pressure molding hotmelt polyamide resin, Spiderbond

-

Model Number:

-

Low pressure molding hotmelt polyamide resin

-

Type:

-

Hot melt Adhesive

-

Main raw materials:

-

Polyamide

-

Condition:

-

Thermoplastic

-

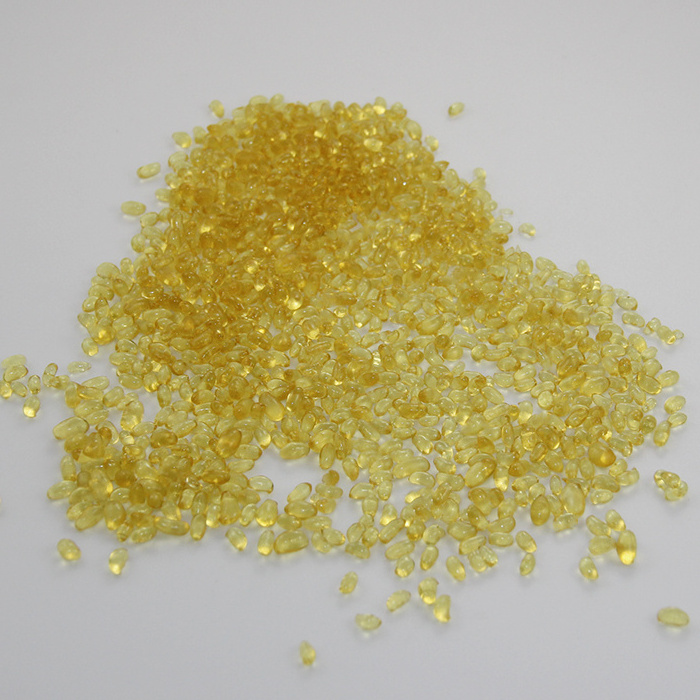

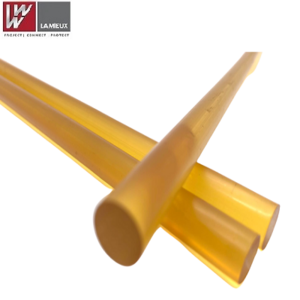

Color:

-

Amber

-

Appearance:

-

Granule

-

MOQ:

-

100kg

-

Payment Terms:

-

T/T, L/C

-

Delivery Time:

-

15-25 days after confirmation

Quick Details

-

CAS No.:

-

63428-84-2

-

Other Names:

-

hotmelt polyamide resin

-

MF:

-

Low pressure molding hotmelt polyamide resin

-

EINECS No.:

-

426-580-9

-

Place of Origin:

-

Anhui, China

-

Brand Name:

-

Low pressure molding hotmelt polyamide resin, Spiderbond

-

Model Number:

-

Low pressure molding hotmelt polyamide resin

-

Type:

-

Hot melt Adhesive

-

Main raw materials:

-

Polyamide

-

Condition:

-

Thermoplastic

-

Color:

-

Amber

-

Appearance:

-

Granule

-

MOQ:

-

100kg

-

Payment Terms:

-

T/T, L/C

-

Delivery Time:

-

15-25 days after confirmation

Product Description

|

Product

|

Polyamide Hot Melt Adhesive

|

|

Grade

|

Industrial, textile, automobile, electronic

|

|

Material

|

Polyamide

|

|

Color

|

Amber, black

|

|

Form

|

Pellet, granular

|

|

Odor

|

Mild

|

|

Packaging

|

20kg/Bag; 25kg/Bag, 600kg/ pallet.

|

|

Application

|

Automotive interior, Home Textiles, Garment & Luggage industry, oil filter, Furniture, Heat transfer printing, Hot stamping, Hot fix Rhinestone, label, etc

|

Product Advantage

1. Excellent bonding strength.

Spiderbond polyamide hot melt adhesive gives excellent bonding strength to different substrates.

2. Excellent high and low temperature resistance.

Spiderbond polyamide hot melt adhesive can resistant -40°C to 220°C.

3. Excellent chemical resistance, waterproof performance and insulation.

Good performance for different applications.

4. Non-toxic and environmental protection

Spiderbond polyamide hot melt adhesive's raw material comes from natural plant, non-toxic & environment protection.

5. Short open time

Save your working hours.

1. Excellent bonding strength.

Spiderbond polyamide hot melt adhesive gives excellent bonding strength to different substrates.

2. Excellent high and low temperature resistance.

Spiderbond polyamide hot melt adhesive can resistant -40°C to 220°C.

3. Excellent chemical resistance, waterproof performance and insulation.

Good performance for different applications.

4. Non-toxic and environmental protection

Spiderbond polyamide hot melt adhesive's raw material comes from natural plant, non-toxic & environment protection.

5. Short open time

Save your working hours.

Application recommendation

|

Automotive

|

Roof/Head-liner, Seat cover, Car Door, Cushion, Sun Visor, Thermal&Acoustic Insulation material, Carpet. etc.

|

|

Wood Working

|

Furniture assembly, cabinet assembly, etc

|

|

Packaging

|

Suitable for almost all kinds flexible packaging.

|

|

Filters

|

Air Filters, Oil Filters, etc.

|

|

Packaging

|

Plastic packaging, metal packaging, paper bonding, lettering film, transfer film, etc.

|

|

Electronics

|

Air filter, oil filter, etc.

|

|

Cable

|

Heat shrinkable tubing, cable adhesive layer, etc.

|

|

Compound Adhesives

|

Compound with EVA, TPU, PES or other kingds of hot melt adhesives to improve performances.

|

Quality Assurance

SPIDERBOND R&D BASE

Advanced R&D team and laboratory from the United States.

PRODUCTION BASE

Professional production team and factory in Asia.

Certifications

FAQ

1. Could I have prices of your products?

Welcome. Pls feel free to send your message at the end of this page. You will get our reply in 24 hours

2. How much is the sample?

Sample will be free. Please contact with us to get the sample for test.

3. Do you inspect the shipping goods?

Yes, the goods will go through pre-production sample inspection and shipping sample inspection by QC department before shipping.

Welcome. Pls feel free to send your message at the end of this page. You will get our reply in 24 hours

2. How much is the sample?

Sample will be free. Please contact with us to get the sample for test.

3. Do you inspect the shipping goods?

Yes, the goods will go through pre-production sample inspection and shipping sample inspection by QC department before shipping.

Recommend Products

Hot Searches