- Product Details

- {{item.text}}

Quick Details

-

Dimensions(L*W*H):

-

6200mm*1850mm*1850mm

-

Weight:

-

6000 KG

-

Max. printing width:

-

850mm

-

Feeding width:

-

850mm

-

Max. unwinding diameter:

-

1300mm

-

Max.winding diameter:

-

1300mm

-

Max. printing size:

-

180-380mm

-

Printing color:

-

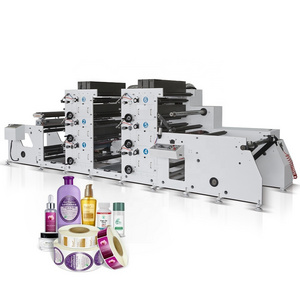

6Color Flexo Printing Machine

Quick Details

-

Place of Origin:

-

Shanghai, China

-

Brand Name:

-

SY

-

Voltage:

-

380V

-

Dimensions(L*W*H):

-

6200mm*1850mm*1850mm

-

Weight:

-

6000 KG

-

Max. printing width:

-

850mm

-

Feeding width:

-

850mm

-

Max. unwinding diameter:

-

1300mm

-

Max.winding diameter:

-

1300mm

-

Max. printing size:

-

180-380mm

-

Printing color:

-

6Color Flexo Printing Machine

Features:

1, Adopts the anilox roller to spread ink.

2, Unwinding and rewinding are controlled by magnetic power brake, clutch, (or by automatic tension controller of Mitsubishi).

3, Each printing unit adopts 360 degree for color registration.

4. Each printing unit has one IR drier.

5. The rubber roller can break away automatically while stopping and running at a low speed in order to avoid ink dried.

6. The main motor is equipped with import stepless regulation of frequency conversion.

7. Unwinding, web guiding, corona treatment,printing, IR drying and rewinding can be finished in one process.

8, An ideal machine to print many kinds of paper rolls before cup making steps.

1, Adopts the anilox roller to spread ink.

2, Unwinding and rewinding are controlled by magnetic power brake, clutch, (or by automatic tension controller of Mitsubishi).

3, Each printing unit adopts 360 degree for color registration.

4. Each printing unit has one IR drier.

5. The rubber roller can break away automatically while stopping and running at a low speed in order to avoid ink dried.

6. The main motor is equipped with import stepless regulation of frequency conversion.

7. Unwinding, web guiding, corona treatment,printing, IR drying and rewinding can be finished in one process.

8, An ideal machine to print many kinds of paper rolls before cup making steps.

|

Model

|

SY-850

|

|

Product name

|

8Color Flexo Printing Machine

|

|

Printing speed

|

50m-60m/min

|

|

Max. printing width

|

850mm

|

|

Feeding width

|

860mm

|

|

Max. unwinding diameter

|

1300mm

|

|

Max.winding diameter

|

1300mm

|

|

Max. printing size

|

180-380mm

|

|

Voltage

|

380V±10%

|

|

Total power

|

48kw

|

|

Weight

|

6000kg

|

|

Dimensions

|

6200mm*1850mm*1850mm

|

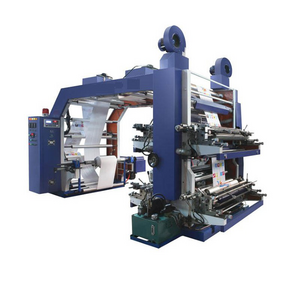

Printing Unit

Printing station comes with ink rubber roller, ceramic anilox cylinder, printing plate cylinder, scrapper blade and ink

container.helical gear

container.helical gear

UV dryer system

The supporting equipment of the printing equipment can provide the efficiency and effect of the finished printing products.

Automatic constant tension control

tension is control pulling material tight or loose.machine come with 2 Set Auto Constant Tension Controller For Unwind and Rewind.

Hydraulic Lifting And Uploading System

Whatever raw material weight is heavy or light, it doesnt need labor to move to unwinding location, it can automatically lift to unwinding location.

automatic Control system

Power Supply, Stop Button, Start Button and Emergency Stop.Temperature Controller for each Heating Oven.Anilox Roller Rotation Button for each Printing Station.Length Counter and Speed Controller4)bottom roller tension control

Video system

It is

Video system

used to check the printing quality in real time while the machine is working. The main purposes are to reduce waste, maximize productivity and improve printing quality.

Hot Searches