- Product Details

- {{item.text}}

Quick Details

-

Warranty:

-

3 months

-

Place of Origin:

-

Hunan, China

-

Brand Name:

-

jinxin

-

Model Number:

-

M2 M3 M4 M5 M6 M8 etc

-

Working Length (mm):

-

none

-

Product name:

-

M3 M4 M5 M6 Flow Bit Tungsten Carbide Friction Drill

-

Size:

-

M2 M3 M4 M5 M6 M8 M10 M12 M14 M16 M18 M20

-

Usage:

-

Flow bit

-

Packing:

-

Plastic Box Packing

-

MOQ:

-

10pcs

-

Materials:

-

Tungsten carbide

-

Suitable for:

-

Steel, alloy steel, iron, steelless

-

Name:

-

Thermal Drill

-

Feature:

-

Durable

-

Application:

-

tapping machine

Quick Details

-

Type:

-

Center Drill Bit, Core Drill Bit, Other

-

Use:

-

tapping machines

-

Finish:

-

Other

-

Warranty:

-

3 months

-

Place of Origin:

-

Hunan, China

-

Brand Name:

-

jinxin

-

Model Number:

-

M2 M3 M4 M5 M6 M8 etc

-

Working Length (mm):

-

none

-

Product name:

-

M3 M4 M5 M6 Flow Bit Tungsten Carbide Friction Drill

-

Size:

-

M2 M3 M4 M5 M6 M8 M10 M12 M14 M16 M18 M20

-

Usage:

-

Flow bit

-

Packing:

-

Plastic Box Packing

-

MOQ:

-

10pcs

-

Materials:

-

Tungsten carbide

-

Suitable for:

-

Steel, alloy steel, iron, steelless

-

Name:

-

Thermal Drill

-

Feature:

-

Durable

-

Application:

-

tapping machine

Products Description

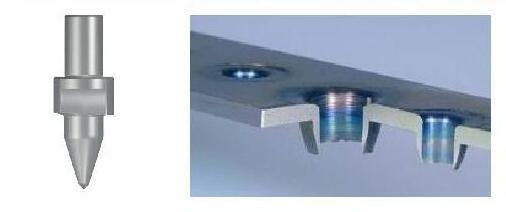

The hot melt drill

is a tapered tool made of special tungsten carbide. It uses high speed rotation and high axial pressure to generate a large amount of frictional heat on a thin tube or plate, where the material at the point of processing is in a "super plastic" state and the tool displaces and shapes this part of the material to form a bushing. The height of the bushing can be 3-4 times the thickness of the original workpiece.

Hot melt drill is widely used in automobiles, motorcycles, construction, decoration, machine tools, machinery, aerospace electronics, electrical appliances, furniture, waterways, shipbuilding and automation equipment and other aspects.

Classification of hot melt drill:

1.According to the surface requirements of the workpiece, the hot melt drill bit can be divided into round hot melt drill and flat hot melt drill.

Round hot melt drill:

The hot melt drill penetrates the workpiece and forms a convex ring on the surface of the workpiece while stretching the forming bushing. This boss is suitable for screw seal or nut washer.

Flat hot melt drill

The middle step of the hot melt bit is grinded with the cutting edge of a milling cutter. When the hot melt drill penetrates the workpiece to form a bushing, the convex ring of the workpiece surface is cut off (milling and chamfering), so that the surface of

the workpiece is smooth.

the workpiece is smooth.

2. According to the thickness of the workpiece, hot melt drill is divided into short hot melt drill and long hot melt drill.

Short drill:

Used for commonly use thin-walled parts. Suitable for penetrating workpiece thicknesses of 0.8mm-3mm. The cylindrical part of the drill is short, and the hole after extrusion into a conical shape can make the tapping strength stronger.

Longer drill:

Used for thicker workpieces or when straight holes need to be processed. It is suitable for tapping workpieces with a thickness of 3-12mm. The cylindrical part of the drill bit is longer and the hole formed after extrusion is longer.

Specification

Use examples of hot melt drill bit(For 2mm low carbon steel)

|

Thread Size

|

Pitch/Inch

|

Diameter(mm)

|

Drilling Machine Speed

(RPM)

|

Drilling Machine Power

(kw)

|

Feed speed

(mm/min)

|

Drilling time

(s)

|

Tapping Machin Speed

(RPM)

|

|

M2

|

0.4

|

1.8

|

3200

|

0.5

|

80

|

2

|

1600

|

|

M3

|

0.5

|

2.7

|

3000

|

0.6

|

100

|

2

|

1350

|

|

M4

|

0.7

|

3.7

|

2600

|

0.7

|

120

|

2

|

1000

|

|

M5

|

0.8

|

4.5

|

2500

|

0.8

|

150

|

2

|

800

|

|

M6

|

1

|

5.3

|

2400

|

1

|

150

|

2

|

650

|

|

M8

|

1.25

|

7.3

|

2200

|

1.3

|

150

|

2

|

500

|

|

M10

|

1.5

|

9.2

|

2000

|

1.5

|

150

|

3

|

400

|

|

M12

|

1.75

|

10.9

|

1800

|

1.7

|

150

|

3

|

330

|

|

M14

|

2

|

13

|

1600

|

2

|

150

|

4

|

300

|

|

M16

|

2

|

14.8

|

1400

|

2.2

|

150

|

4

|

250

|

|

M18

|

2.5

|

16.7

|

1400

|

2.5

|

150

|

5

|

220

|

|

M20

|

2.5

|

18.7

|

1200

|

2.7

|

150

|

5

|

200

|

Product Show

Application scenarios

Main Products

Q: Are you trading company or manufacturer ?

A: We are professional manufacturer, have more than 15 years experience in this field.

Q: Can you send products to our Forwarder in China?

A: Yes, if you have Forwarder in China,we will glad to send products to him/her.

Q.Do you inspect the finishing products?

Yes, each product will be inspected by our QC before shipping.

Q.What's your shipment term?

DHL, UPS, TNT, FedEx, SF-Express, EMS, 5-8 days will arrived.

Q.What is the shipping cost?

It mainly depends on weight, volume, packing size and destination port.

Q.What's your delivery time?

In stock, 1-2 days, if not, according to your quantity.

A: We are professional manufacturer, have more than 15 years experience in this field.

Q: Can you send products to our Forwarder in China?

A: Yes, if you have Forwarder in China,we will glad to send products to him/her.

Q.Do you inspect the finishing products?

Yes, each product will be inspected by our QC before shipping.

Q.What's your shipment term?

DHL, UPS, TNT, FedEx, SF-Express, EMS, 5-8 days will arrived.

Q.What is the shipping cost?

It mainly depends on weight, volume, packing size and destination port.

Q.What's your delivery time?

In stock, 1-2 days, if not, according to your quantity.

Hot Searches