- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

SCK

-

Voltage:

-

110V/220V

-

Power:

-

2KW

-

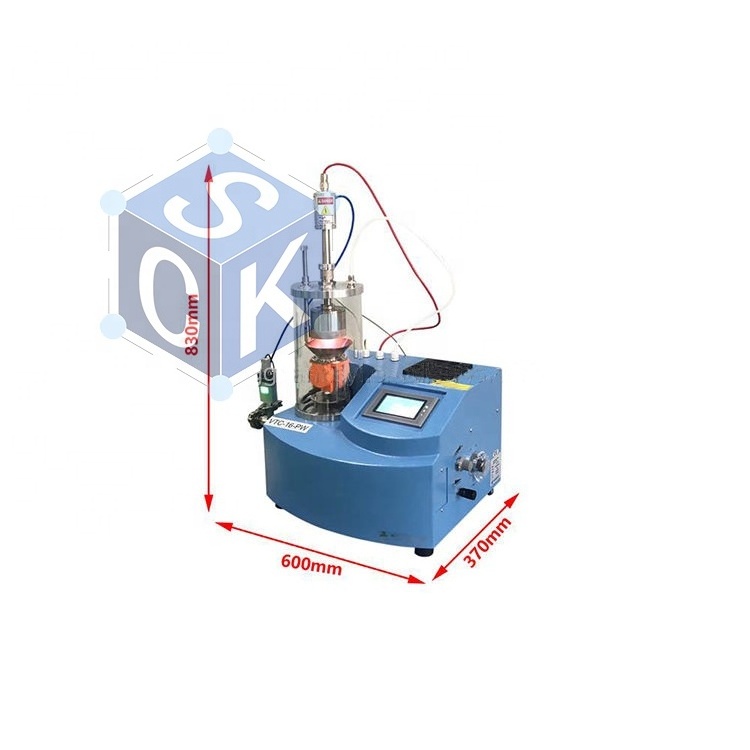

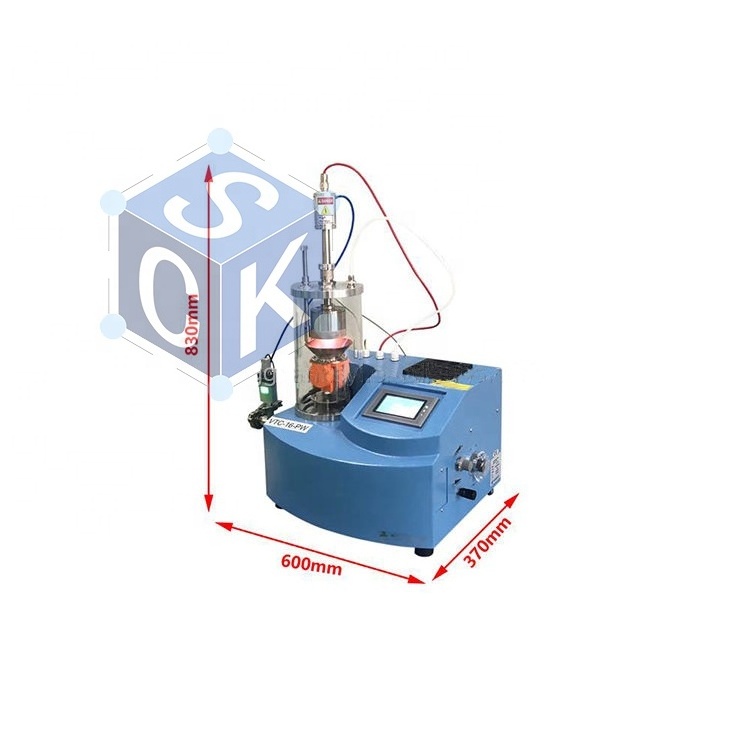

Dimension(L*W*H):

-

Customized Size

-

Weight (KG):

-

20

-

Product name:

-

Lab high vacuum magnetron sputtering coating machine

-

Cavity material:

-

stainless steel

-

power supply:

-

RF/DC(optional)

-

Magnetron Sputtering Head:

-

2"

-

Number of magnetic targets:

-

1 pieces

-

Sample holder size:

-

dia 140mm

-

accuracy:

-

±1

-

Company attributes:

-

manufacturer

Quick Details

-

Machine Type:

-

coating, Coating Equipment

-

Marketing Type:

-

2023

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

SCK

-

Voltage:

-

110V/220V

-

Power:

-

2KW

-

Dimension(L*W*H):

-

Customized Size

-

Weight (KG):

-

20

-

Product name:

-

Lab high vacuum magnetron sputtering coating machine

-

Cavity material:

-

stainless steel

-

power supply:

-

RF/DC(optional)

-

Magnetron Sputtering Head:

-

2"

-

Number of magnetic targets:

-

1 pieces

-

Sample holder size:

-

dia 140mm

-

accuracy:

-

±1

-

Company attributes:

-

manufacturer

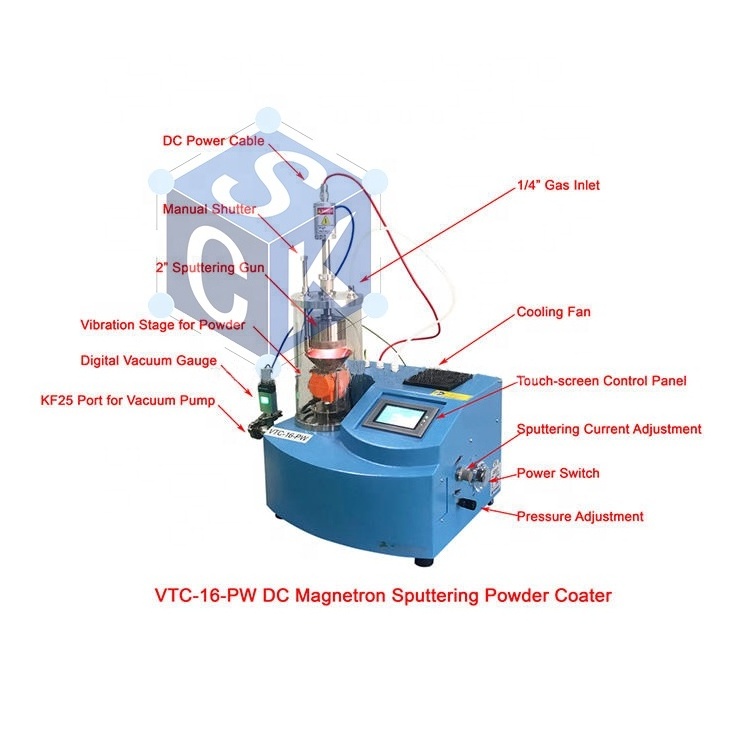

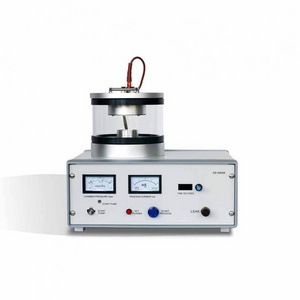

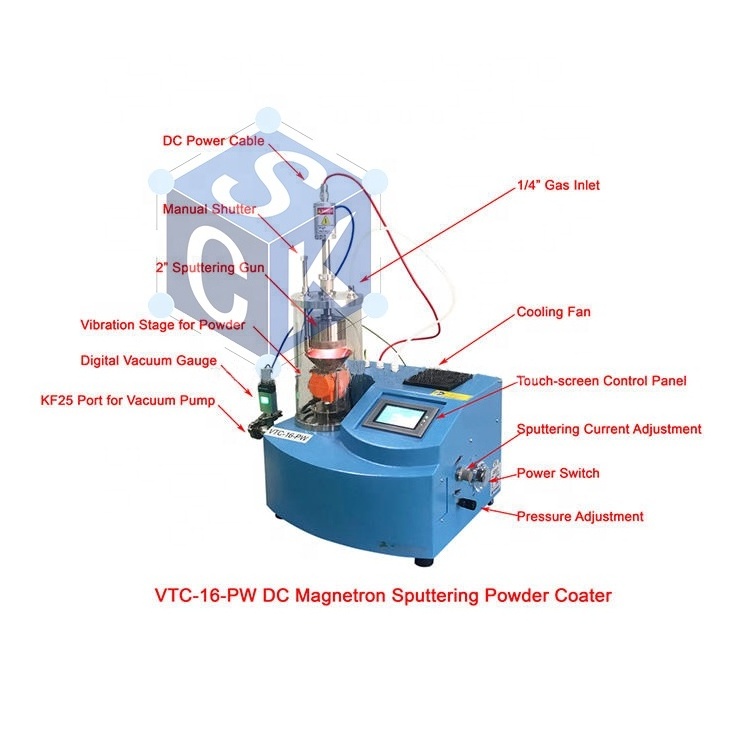

Laboratory Magnetron Plasma Sputtering Coater bench top Sputtering system for coating silver, gold and bronze on Resin Polymer- VTC-16-D

VTC-16-D is a small DC magnetron plasma sputtering coater with a target gun diameter of 2 inches and an adjustable sample stage height. This sputtering coater is mainly used to produce some metal coatings.

Technical parameters:

| Equipment name and model | Single target magnetron plasma sputtering coater VTC -16-D |

| C haracteristic |

· Compact size, easy to operate, and easy to use

|

| Basic parameters |

·Input power supply: 220V, 50/60HZ

|

| Sputtering chamber |

·Quartz chamber size: outer diameter φ 166mm × internal diameter φ 150mm × 150mm high ·Sealed with fluorine rubber O-ring ·A manually operated baffle is installed on the flange cover for pre sputtering of the target material. One φ 6.35 ferrule joint is the air inlet, used to connect the intake pipe. A manual air release valve is used to charge air into the quartz chamber. ·A stainless steel mesh cover covers the entire quartz cavity to shield the plasma |

|

·By adjusting the micro precision regulating valve on the right side of the casing to control the flow rate of working gas entering the quartz chamber, the vacuum degree inside the chamber is adjusted ·The sputtering current is controlled by adjusting the Potentiometer on the right side of the housing. |

|

| Target head and target material |

· A 2-inch magnetron sputtering target without water cooling, with a maximum operating temperature of 80 degrees Celsius. If the temperature exceeds 80 degrees Celsius, the magnetron sputtering target will lose its magnetism and cannot function. ·Sputtering time: 1-120s adjustable ·Standard with a copper target ·Target size requirements: φ 2 ″ * (0.5-5) mm thickness ·Suitable for sputtering Au, Ag, Cu, and other metals (available for purchase at our company) |

| S ample stage |

·A sample stage with adjustable height, with an adjustable distance of 25-70mm between the sample stage and the target material ·Sample table size: φ 2 inches ·The sample stage can be equipped with optional heating function, with a maximum heating temperature of 500 degrees; |

| Pirani gauge |

· Measurement range: 1 * 10-4 mbar-1000 mbar (1 * 10-4-750 torr) ·Accuracy: 1000mbar-20 mbar (30% of reading) 20-0.002mbar (2% of reading) ·Repeatability: 20-0.002mbar (2% of reading) ·Operating humidity: ≤ 80% in a 30 ℃ environment, ≤ 50% in a 40 ℃ environment, without condensing gas; ·Operating temperature: 5 ℃ -60 ℃ |

| Thin film thickness gauge (optional) |

· A precision quartz vibration thin film thickness gauge is installed on the instrument, which can monitor the thickness of the thin film in real time, with a separation rate of 0.10 Å

|

| Vacuum system (optional) |

·Model: VRD-8

|

| Equipment usage requirements |

· To achieve the desired film thickness, multiple sputtering coatings can be performed

·Before sputtering coating, ensure the cleanliness of the sputtering head, target material, substrate, and sample stage ·To achieve good adhesion between the film and substrate, clean the surface of the substrate before sputtering |

| Overall dimensions | 5 0 0*350*550 mm (length * width * height) |

| W eight | About 20KG (excluding vacuum pumps, water cooling equipment, vacuum systems, etc.) |

| Warranty |

·One year warranty, lifetime technical support

1. Consumables such as heating elements, quartz tubes, sample crucibles, etc. are not included in the warranty scope 2. Damage caused by the use of corrosive and acidic gases is not covered by the warranty |

| MaMatters needing attention |

·The air pressure inside the chamber should not exceed 0.02MPa (relative air pressure);

·Due to the high internal pressure of the gas cylinder, a pressure reducing valve must be installed on the gas cylinder when introducing gas into the quartz tube. To ensure safety, it is recommended to use a pressure lower than 0.02MPa. It is recommended to purchase a pressure reducing valve from our company, with a range of 0.01MPa-0.1MPa, which will be more precise and safe when used; ·We do not recommend customers to use flammable, explosive, or toxic gases. If the customer's process requires the use of flammable, explosive, or toxic gases, please take relevant protective and explosion-proof measures yourself. Our company is not responsible for any issues caused by the use of flammable, explosive or toxic gases. |

PACKAGE:

1 Standard exported package: Internal anticollision protection, external export wooden box packaging.

2 Shipping by express, by air, by sea according to customers' requirements to find the most suitable way.

3 Responsible for the damage during the shipping process, will change the damage part for you for free.

DELIVERY TIME:15-20 days after confirming order,detail delivery date should be decided according to production season and order quantity.

1. If you are interested in our products, please tell us the model number and quantity.

2. We will make a proforma invoice for your order.

3. We will deliver the product ASAP on receipt of the payment

1. Guarantee for one year after shipment.

1.Telegraphic transfer

2.Western Union

3.Secure Payment through Alibaba

4.L/C