- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

Macreat

-

Voltage:

-

380V

-

Dimension(L*W*H):

-

2600*1300*2300mm

-

Motor Power (Kw):

-

160

-

Power (kW):

-

1260

-

Weight (KG):

-

110000 KG

-

Marketing Type:

-

New Product 2023

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Raw material:

-

log wood,wood waste,mixture of wood kinds

-

Application:

-

producing high quality wood pellets from wood to packing

-

Capacity:

-

5-6 ton per hour 5-6t/h

-

Product name:

-

complete biomass wood pellet machine production line

-

Color:

-

White and blue or Customer's Request

-

moisture:

-

less than 15%

-

temperature:

-

60-80° wood pellet production line

-

application:

-

energy, boiler and electricity

-

Pellet diameter:

-

4-12mm 5-6 T/H pellet production line/complete biomass production line

Quick Details

-

Pellet Diameter (mm):

-

6 - 10

-

Output (kg/h):

-

4000 - 6000 kg/h

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Macreat

-

Voltage:

-

380V

-

Dimension(L*W*H):

-

2600*1300*2300mm

-

Motor Power (Kw):

-

160

-

Power (kW):

-

1260

-

Weight (KG):

-

110000 KG

-

Marketing Type:

-

New Product 2023

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Raw material:

-

log wood,wood waste,mixture of wood kinds

-

Application:

-

producing high quality wood pellets from wood to packing

-

Capacity:

-

5-6 ton per hour 5-6t/h

-

Product name:

-

complete biomass wood pellet machine production line

-

Color:

-

White and blue or Customer's Request

-

moisture:

-

less than 15%

-

temperature:

-

60-80° wood pellet production line

-

application:

-

energy, boiler and electricity

-

Pellet diameter:

-

4-12mm 5-6 T/H pellet production line/complete biomass production line

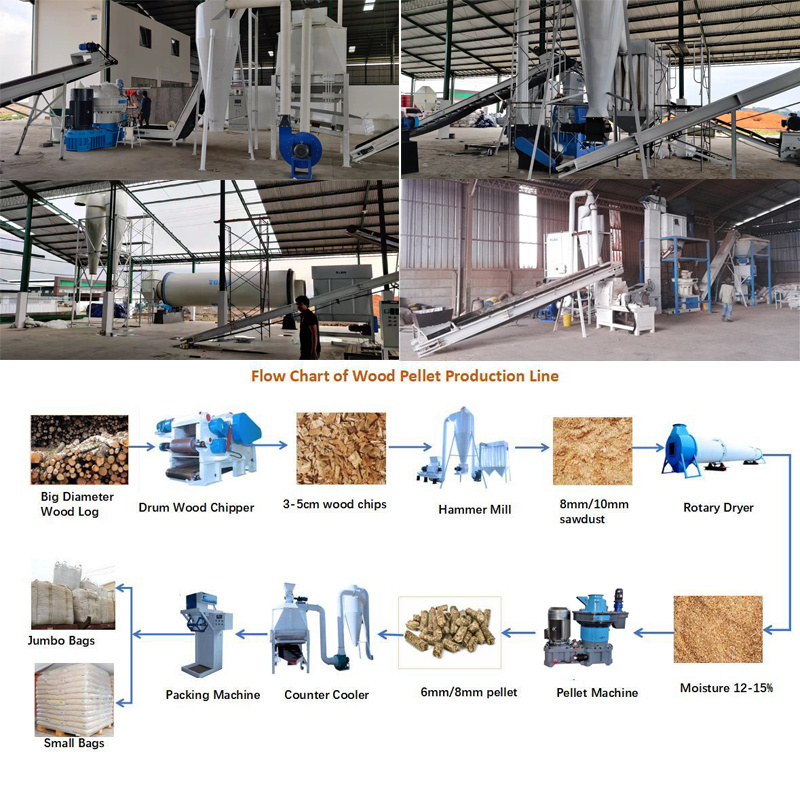

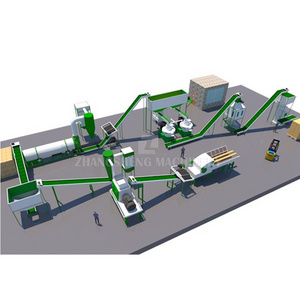

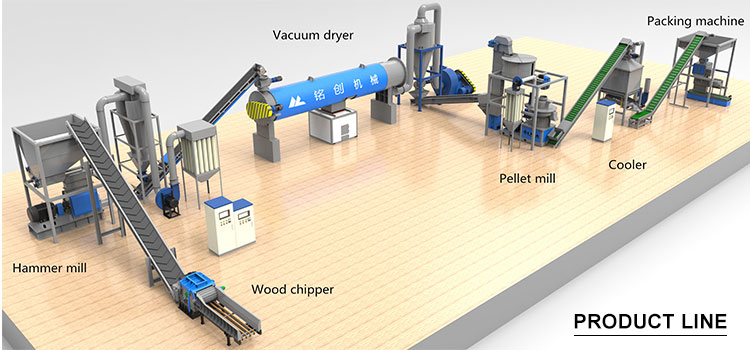

Products Advantages

MACREAT pallets machine line wood pellet production wood pellet mill line 1 tons biomass wood pellet machine sawdust line

wood pellet production line

●

S

ix Sections:

Crushing--

Hammer Mill--

Drying--

Pelletizing--

Cooling--

Packing

●

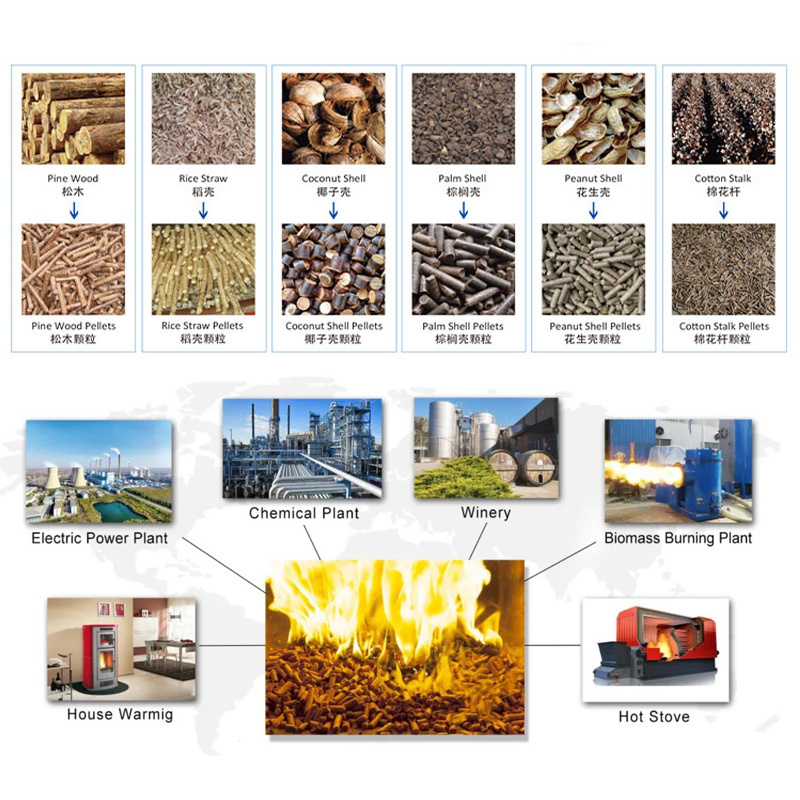

There are a wide range of raw materials suitable for biomass particles, including the following categories:

Forestry: such as eucalyptus, pine, birch, poplar, Malacca and wood bark branche, etc.

A

gricultural wastes: corn straw, wheat straw, peanut husk, rice husk, bamboo, etc.

Waste wood: furniture factory waste materials, waste pallets, sheets, shavings, sanding powder, etc.

Different material need different machine.

Take wood log as an example,the whole process include:

1)Drum wood chipper -To make wood log into small size wood chips.

2)Hammer mill/Crusher - To make wood chips into sawdust.

3)Dryer- To dry the high moisture content of sawdust into 12-15%.

Take wood log as an example,the whole process include:

1)Drum wood chipper -To make wood log into small size wood chips.

2)Hammer mill/Crusher - To make wood chips into sawdust.

3)Dryer- To dry the high moisture content of sawdust into 12-15%.

4)Pellet mill-

The dry sawdust are pressed by a pellet machine into pellets with a diameter of 6 or 8 mm.

5)Cooler- Reduce the temperature of pellets to room temperature.

6)Packing machine- Pack the pellets into the bag according to the set weight.

5)Cooler- Reduce the temperature of pellets to room temperature.

6)Packing machine- Pack the pellets into the bag according to the set weight.

The range of raw materials is very wide, and all biomass materials are available. such as the rice husk,sunflower seed husk,peanut shell and other fruit shell;branch,trunk,bark and other wood waste;a variety of corp straws.

Biomass pellets are alternative fuels to non-renewable energy sources such as coal, petroleum, and natural gas, which can save energy and reduce carbon emissions. It is an efficient and clean renewable energy source. They can obtain heat energy through combustion and are widely used in life heating, power generation and other fields.

Product Details

Wood chips making machine

For the first crushing section, this section use wood crusher or wood chipper to making wood chips from wood logs or wood waste.The size of finished wood chips is 3-5 cm.

Hammer mill

Use high efficiency hammer mill to produce wood sawdust (size is 3-5 mm) from wood chips. Our wood hammer mill can use for different raw material, such as wood chips, wood shavings and palm shell.

Dryer machine

If the moisture of raw material is more than 15%, we have to use dryer to reduce the water content. Then the sawdust could be put into pellet mill machine.

Pellet mill

The most important section of the whole line. At this section,we choose

to use the vertical ring die pellet mill which is designed for producing biomass pellet specially.

Cooling machine

The pellet produced is too hot to pack directly. The temperature can produce hot air in bags. The pellet will easy to cracks too.So we need to cool down the temperature before packing.

Packing machine

After cooling, the pellet is ready enough to pack.Packing machine is mainly used to pack the pellets in requirement capacity to bags and seals bags automatically.

Factory Show

Macreat (Shandong) Machinery Co., Ltd

is located in Mingshui Economic Development Zone, Zhangqiu District, Jinan City, Shandong Province. It is a group enterprise specialized in R&D, manufacturing and sales of biomass energy equipment. The company, formerly known as Yantai Lida Woodworking Machinery Co., LTD, is located in Muping District, Yantai City, Shandong Province, with a total investment of more than ¥50 million and an area of 35,000 square meters.

It has more than 100 employees and 60 years of machinery manufacturing experience and 30 years of export experience. The company's sales center is located in Jinan, the existing sales staff of more than 50 people, annual sales of more than $15 million.

Your trust is the beginning of our cooperation , we sincerely look forward to cooperating with you!

The company upholds the pursuit of intellgence , efficiency and safety , and aims at the perfection in product and technology .Mlacreat makes achiecement of customer's demands a top priority and considers the high quality of the products as origin of the company's life.Form the beginning of each process to the delivery of each product , we implement the quality tracking system and establish a perfect customer support scheme for each user

We have already got ISO9001 certificate and EU CE certification

.Reliable and stable product quality has won our company a good reputation . It also leads to high sales and top-ranked comprehensive economic indicators among domestic manufacturers .

At present , the products have been sold all the country and expoeted to more than 90 countries and regions , such as Gny . Finland . Russia . NeyZealand , South Korea , Pakistan , India , Bangladesh ,Vietnam , Malaysia and Turkey.

Your trust is the beginning of our cooperation , we sincerely look forward to cooperating with you!

Macreat Exhibition

Customer Case

Certifications

Packing & Shipment

Delivery

A, By Express (DHL, TNT, FedEX, EMS)

B, For big orders, We will send you the goods by Sea to your close sea port.

A, By Express (DHL, TNT, FedEX, EMS)

B, For big orders, We will send you the goods by Sea to your close sea port.

FAQ

1.Q:HOW ABOUT THE QUALITY OF YOUR PRODUCTS?

A:Our products are strictly made by adopting advanced technology both at home and abroad.

Every aspect of our products is under strict quality control and we take a test on each equipment before delivery. We area manufacturer having over 50 years ‘experience in manufacturing all kinds of China-made woodworking machinery since 1960.You can also use Trade Assurance by Alibaba for product quality

protection, on-time shipment protection and payment protection.

2.Q:HOW LONG IS YOUR GUARANTEE?

A:One Year (Calculated from the equipment arrives the customer ‘s side).

3.Q:DO YOU PROVIDE AFTER-SALE SERVICE?

A:Yes. We provide one-year warranty to make sure your machine runs consistently. Besides, we always offer lifelong services and provide spare parts for a long term. And we repair main parts under correct using for free in two years.

4.Q:WILL YOU SEND ENGINEERS TO INSTALL THE PLANT?

A:yes, but at an extra cost payable by the customer. Or you can get local contractors to do the commissioning and we send one supervising engineer.

A:Our products are strictly made by adopting advanced technology both at home and abroad.

Every aspect of our products is under strict quality control and we take a test on each equipment before delivery. We area manufacturer having over 50 years ‘experience in manufacturing all kinds of China-made woodworking machinery since 1960.You can also use Trade Assurance by Alibaba for product quality

protection, on-time shipment protection and payment protection.

2.Q:HOW LONG IS YOUR GUARANTEE?

A:One Year (Calculated from the equipment arrives the customer ‘s side).

3.Q:DO YOU PROVIDE AFTER-SALE SERVICE?

A:Yes. We provide one-year warranty to make sure your machine runs consistently. Besides, we always offer lifelong services and provide spare parts for a long term. And we repair main parts under correct using for free in two years.

4.Q:WILL YOU SEND ENGINEERS TO INSTALL THE PLANT?

A:yes, but at an extra cost payable by the customer. Or you can get local contractors to do the commissioning and we send one supervising engineer.

Hot Searches