1) Reinforce aluminum cast-solid ring with strong structure makes steady in wrapping

2) The higher level main board with stronger structure and frame for wrapping.

- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

380V 50Hz 3p

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

Chinaeps

-

Dimension(L*W*H):

-

2970*1520*2200 mm

-

Weight:

-

2600 KG

-

Certification:

-

CE

-

Marketing Type:

-

Hot Product 2023

-

Product name:

-

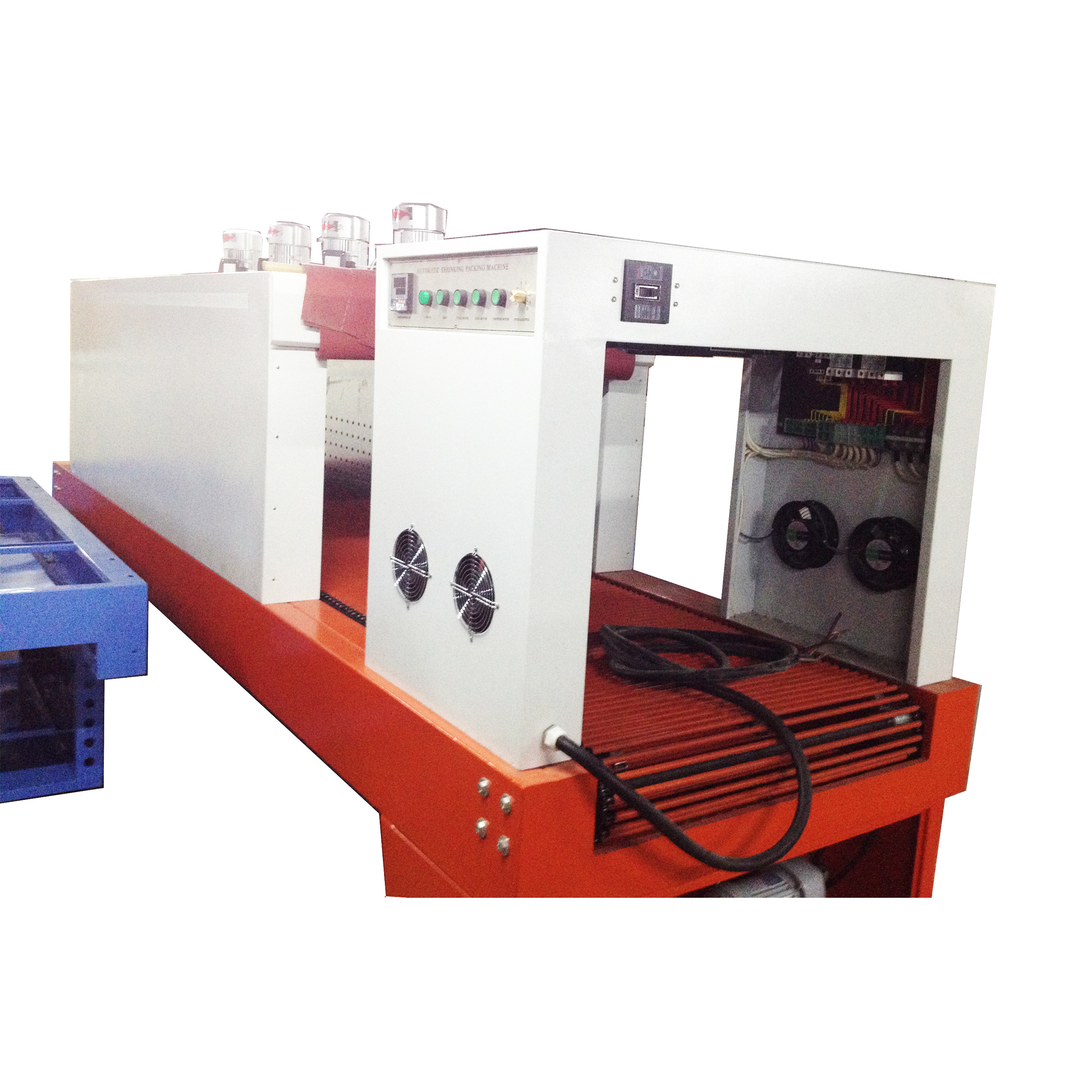

Automatic Film Shrink Wrapping Machinery

-

Packing material:

-

PE POF PVC Film

-

Packing speed:

-

4000~6000pcs/hour

-

Reducing Motor:

-

GPG

-

Temperature Control:

-

Autonics

-

Insulation:

-

Aluminum Silicate

-

Automatic:

-

Yes

-

Thermal Overload Relay:

-

Delixi

-

Frequency Inverter:

-

Schneider

Quick Details

-

Packaging Type:

-

Film, Foil

-

Packaging Material:

-

pvc

-

Driven Type:

-

Electric

-

Voltage:

-

380V 50Hz 3p

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

Chinaeps

-

Dimension(L*W*H):

-

2970*1520*2200 mm

-

Weight:

-

2600 KG

-

Certification:

-

CE

-

Marketing Type:

-

Hot Product 2023

-

Product name:

-

Automatic Film Shrink Wrapping Machinery

-

Packing material:

-

PE POF PVC Film

-

Packing speed:

-

4000~6000pcs/hour

-

Reducing Motor:

-

GPG

-

Temperature Control:

-

Autonics

-

Insulation:

-

Aluminum Silicate

-

Automatic:

-

Yes

-

Thermal Overload Relay:

-

Delixi

-

Frequency Inverter:

-

Schneider

Product Description

Machine Introduction

The machine adopts PLC programmable industrial controller and computer touch screen to complete the automatic cycle process of pushing, winding, packaging, sealing and cutting of the product to the working position

The machine has stable performance, simple operation, no noise and low power consumption;

The machine can be matched with various EPS products and equipment, packaging various specifications of EPS products

Machine Features

1.1 It is used to pack EPS shaping product. It is fast packing and saves film.

1.2 The machine is suitable for various kind of dimensions.

1.4 It is protected by fences and raster, to insure safety.

1.3 It is full automatic, controlled by Siemens PLC and touch screen.

1.6 Frequently-used specification can be record and easy to load.

1.5 Equipped with malfunction warning system, easy to remove problem.

1.2 The machine is suitable for various kind of dimensions.

1.4 It is protected by fences and raster, to insure safety.

1.3 It is full automatic, controlled by Siemens PLC and touch screen.

1.6 Frequently-used specification can be record and easy to load.

1.5 Equipped with malfunction warning system, easy to remove problem.

Wrapping Station

Conveyor

1) Structure of the conveyor will protect the surface of the product.

2) Automatic infeed conveyor system and outfeed conveyor system.

3) Conveyors driven by motor with gear box.

4) Diferent type conveyors available via package

2) Automatic infeed conveyor system and outfeed conveyor system.

3) Conveyors driven by motor with gear box.

4) Diferent type conveyors available via package

Automatic material cutter

1) Automatic material feeding and cutting device.

2) Automatic material clamping for next wrapping.

3) Sensor and PLC program control.

4) The operation parameter is adjustable.

5)This device makes machine automatically and unmanned operation.

2) Automatic material clamping for next wrapping.

3) Sensor and PLC program control.

4) The operation parameter is adjustable.

5)This device makes machine automatically and unmanned operation.

Specification

|

Item

|

Unit

|

Specification

|

|

Suitable for length

|

mm

|

2000

|

|

Suitable for width

|

mm

|

600-800

|

|

Suitable for height

|

mm

|

300-600

|

|

Cycle time(1200*800*600mm)

|

s

|

30

|

|

Power

|

Kw

|

4.5

|

|

Contour size

|

mm

|

7500*1800*2500

|

Applications

suitable for both eps foam sheet or eps foam fish boxes.

Company Profie

EPS INDUSTORY ENGINEERING CO., LTD.

An EPS / EPP / ETPU foam plastic machinery equipment, mold and raw material manufactory, integrating independent professional research and development, manufacturing, sales and service. We have strong product design and development capabilities. The company is composed of senior people with more than 20 years of experience in foam machine development, design and manufacturing, and is fully responsible for the research and development of new products of our company.

We are specialized in EPS ( expandable polystyrene ) styrofoam polyfoam raw material and Polyfoam EPS machine: block molding machine, pre expander machine, EPS cutting machine. The company's products have high production efficiency and energy Low consumption, stable and durable, convenient maintenance and so on. We are committed to the promotion of the EPS block machine, packaging machine and automatic cutting line origin from China with Chinese characteristics, high quality & reasonable price. We have erected a bridge for worldwide EPS users engaged in EPS industry to communicate better with each other. Therefore, our customers save a lot of travel costs and time, especially reduce a large number of losses due to quality claims in the disputes with our familiar Chinese laws. We're not proud of selling cheap products to our customers, but proud of helping our customers solve purchasing problems.

We are specialized in EPS ( expandable polystyrene ) styrofoam polyfoam raw material and Polyfoam EPS machine: block molding machine, pre expander machine, EPS cutting machine. The company's products have high production efficiency and energy Low consumption, stable and durable, convenient maintenance and so on. We are committed to the promotion of the EPS block machine, packaging machine and automatic cutting line origin from China with Chinese characteristics, high quality & reasonable price. We have erected a bridge for worldwide EPS users engaged in EPS industry to communicate better with each other. Therefore, our customers save a lot of travel costs and time, especially reduce a large number of losses due to quality claims in the disputes with our familiar Chinese laws. We're not proud of selling cheap products to our customers, but proud of helping our customers solve purchasing problems.

Pre-Sales Service

* Inquiry and technical consulting support.

* Sample testing support.

* Study travel to your Factory and know your need.

* Solution drawing per specification

* Our factory visiting.

* Sample testing support.

* Study travel to your Factory and know your need.

* Solution drawing per specification

* Our factory visiting.

After-Sales Service

* Installation & commissioning with training how to instal the packaging machine, training how to use the machine.

* Engineers available to service machinery overseas.

* Online technical support.

* Modification service

* Engineers available to service machinery overseas.

* Online technical support.

* Modification service

Exhibition&Certifications

FAQ

Q. Are you EPS foam wrapping machine factory or trading company?

A: We are a EPS foam machine manufactory located in Jiangyin, Wuxi. We are professional in EPS foam block cutting machine, EPS foam block molding machine, EPS foam box wrapping machine and so on.

Q. How can I get your factory?

A: By air: You can take a plan to WUXI airport from China, if you fly from Korea, Japan, USA, Singapore, Taiwan, Thailand you will can directly fly to us.

By Train: You can stop at WUXI station, Not WUXI EAST station.

Q. Do you provide pick-up service?

A: Yes, of course. If you are in Wuxi airport or station, we can arrange a special car to pick you up directly to our factory.

Q. Do you accept EPS Foam Machine customization?

A: Yes, of course. We can adjust our EPS foam all kind of machine's parameter, design and size to be suitable for your EPS foam block or box or other products.

Q. How long is your EPS foam casting machine warranty?

A: 1 year. Within one yea, if it is not man-made damage, we will provide free replacement parts, but the shipping cost needs to be paied by the customer.

Q. What if I can't install it after I get the EPS foam cutting, molding, wrapping or other machine? Do you offer installation services?

A: Yes, we supply video technical support. If your company has engineer, you can come to our factory, we will provide field installation, commissioning and training. Of course, our engineers are available to service machinery overseas.

Q. What is your terms of payment?

A: T/T 30% as deposit, and 70% before delivery. We'll show you the photos of the products and packages before you pay the balance. Other payment terms can also be negotiated.

Q. What is your terms of delivery?

A: EXW, FOB, CFR, CIF. Q. How about your delivery time? A: Generally, it will take 20 to 60 days after receiving your advance payment. The specific delivery time depends on the items and the quantity of your order.

Q. Can you produce according to the samples?

A: Yes, we can produce mold by your samples or technical drawings.

Q. Do you test all your machines before delivery?

A: Yes, we have 100% test before delivery.

Q. Do you have some videos where we can see the line producing?

A: Yes, we can provide some videos for reference.

Q: How do you make our business long-term and good relationship?

A:1. We keep good quality, competitive price and 24 hours one to one sercive to ensure our customers benefit ; 2. We respect every customer as our friend and we sincerely do business and make friends with them, no matter where they come from.

Hot Searches