- Product Details

- {{item.text}}

Quick Details

-

Power:

-

depends

-

Dimension(L*W*H):

-

depends

-

Weight:

-

5000 KG

-

Application:

-

Mechanical Vapor Recompression MVR evaporation system

-

Main parts:

-

Heater and separator

-

Stage of effector:

-

4

-

Flow:

-

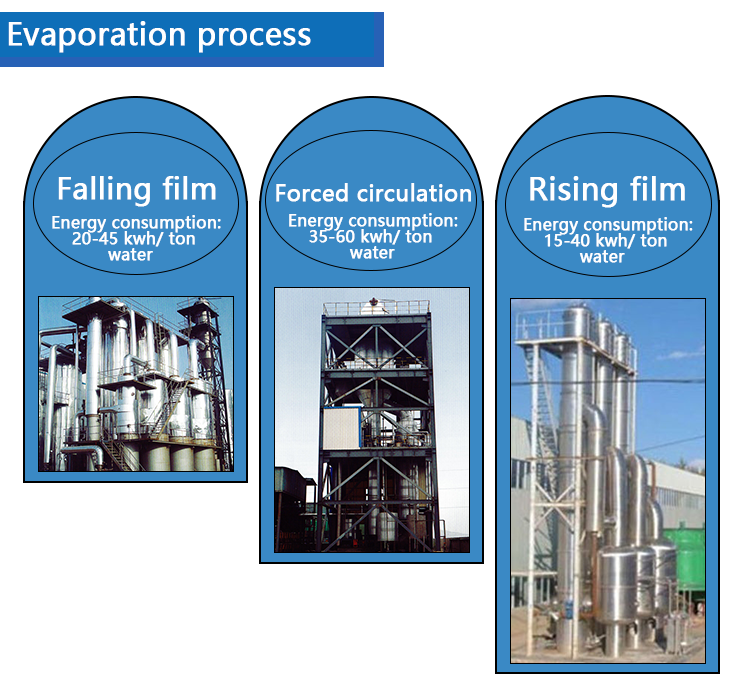

Falling film,forced circulation,increasing film

-

Characteristic:

-

Reduce steam consumption and cooling media consumption

-

Capacity:

-

0.5-120 cubic meters/h

-

Advantage:

-

Consumption saving,low run expense

-

Function:

-

Wastewater, sewage, envorimental, food, salt

Quick Details

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

Hanpu

-

Voltage:

-

220/380/440V

-

Power:

-

depends

-

Dimension(L*W*H):

-

depends

-

Weight:

-

5000 KG

-

Application:

-

Mechanical Vapor Recompression MVR evaporation system

-

Main parts:

-

Heater and separator

-

Stage of effector:

-

4

-

Flow:

-

Falling film,forced circulation,increasing film

-

Characteristic:

-

Reduce steam consumption and cooling media consumption

-

Capacity:

-

0.5-120 cubic meters/h

-

Advantage:

-

Consumption saving,low run expense

-

Function:

-

Wastewater, sewage, envorimental, food, salt

Product Description

MVR SYSTEM INTRODUCTION

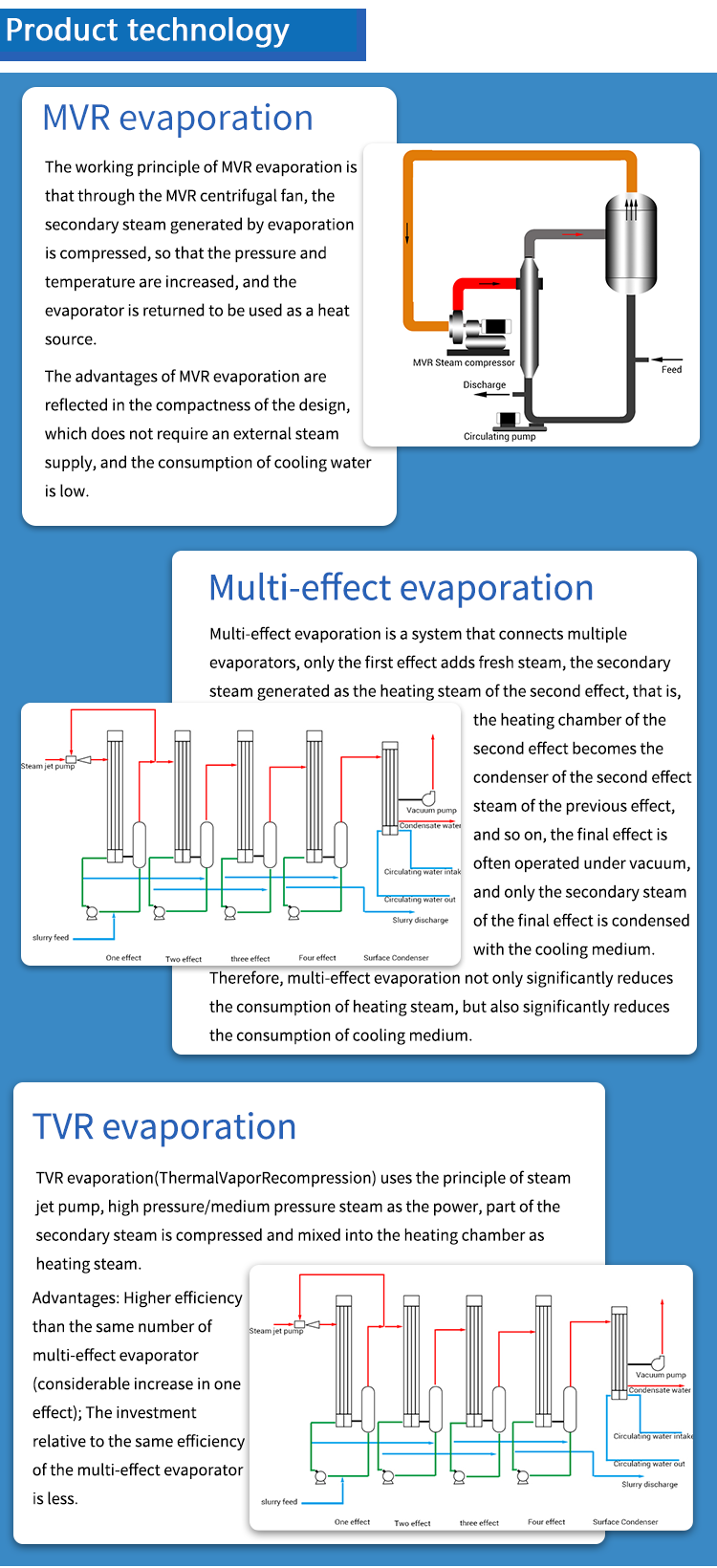

Mechanical vaporization re-compression system, which is called MVR which principle is to compress the second steam generated by evaporator by high efficiency steam compressor; this process transfers electric energy to eating energy and higher the pressure and temperature of second steam. The second steam with higher temperature will be sent to evaporation room to heat the product for evaporation. So the latent heat of vaporization of the second steam can be circularly used. Making use of less energy which is the mechanical energy of compressor blade wheel as the compression heat pump, energy is added into the heating medium and is circularly used in heating process. Under this circumstance, no need to add first steam as heating medium.

MVR SYSTEM ADVANTAGE

(1)Lowest energy consumption and operation cost, electricity consumption of one ton water’s evaporation is 15-50kw. (2)Temperature difference is small, heating is gentle, the loss of product is less.

(3)Compact structure and lower building cost; plant area is 50% less than that of traditional evaporator.

(4)Surrounding is friendly, no gas and no steam.

(5)Good adaptability in low loading condition, flexibility of operation is good and has a longer service life.

(6)Consumption of circular water is low and energy saving is obvious.

(7)No fresh steam is needed.

(8)Evaporation can be carried out under 40℃ and equipment need not to be frozen, specially suitable for thermal activity products.

(3)Compact structure and lower building cost; plant area is 50% less than that of traditional evaporator.

(4)Surrounding is friendly, no gas and no steam.

(5)Good adaptability in low loading condition, flexibility of operation is good and has a longer service life.

(6)Consumption of circular water is low and energy saving is obvious.

(7)No fresh steam is needed.

(8)Evaporation can be carried out under 40℃ and equipment need not to be frozen, specially suitable for thermal activity products.

|

Effective number

|

1

|

2

|

3

|

4

|

5

|

6

|

7

|

8

|

|

Steam consumption

(t steam/ t water) |

~1.04

|

~0.53

|

~0.36

|

~0.28

|

~0.23

|

~0.19

|

~0.17

|

~0.15

|

Application

Application

Applied to multiple areas, such as: "zero release" solution for industrial waste water, Evaporation and concentration for process industry, food fermentation (aginomoto, citric acid, starch and sugar), fine chemical (pesticide, synthetic dyes, organic pigments, paints, spice and essence, cosmetic), chlorine chemical (salt water concentration), seawater desalt and metallurgical industry, etc.

Applied to multiple areas, such as: "zero release" solution for industrial waste water, Evaporation and concentration for process industry, food fermentation (aginomoto, citric acid, starch and sugar), fine chemical (pesticide, synthetic dyes, organic pigments, paints, spice and essence, cosmetic), chlorine chemical (salt water concentration), seawater desalt and metallurgical industry, etc.

Hot Searches