- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

Hongfa

-

Voltage:

-

380v, 220v, 450v, 380V,50HZ/60HZ,3 phase

-

Power:

-

75kw

-

Dimension(L*W*H):

-

1910x1610x4320mm

-

Weight:

-

8900 kg

-

Cycle time:

-

12~18min (Determined by the diameter)

-

Roller diameters:

-

127 mm( dia 300-600), 216 mm (dia 600-1200)

-

Certification:

-

ISO9001/CE/TUV, ISO9001/CE

-

Color:

-

Optional

-

Processing Type:

-

concrete pipe making machine

-

After Warranty Service:

-

Online & Video technical support

-

Pipe shape:

-

Rabbet, socket, flat

Quick Details

-

Pipe Material:

-

CONCRETE, Stainless steel

-

Production Capacity:

-

16~48 piece/8 hours

-

Place of Origin:

-

Guangxi, China

-

Brand Name:

-

Hongfa

-

Voltage:

-

380v, 220v, 450v, 380V,50HZ/60HZ,3 phase

-

Power:

-

75kw

-

Dimension(L*W*H):

-

1910x1610x4320mm

-

Weight:

-

8900 kg

-

Cycle time:

-

12~18min (Determined by the diameter)

-

Roller diameters:

-

127 mm( dia 300-600), 216 mm (dia 600-1200)

-

Certification:

-

ISO9001/CE/TUV, ISO9001/CE

-

Color:

-

Optional

-

Processing Type:

-

concrete pipe making machine

-

After Warranty Service:

-

Online & Video technical support

-

Pipe shape:

-

Rabbet, socket, flat

Product Description

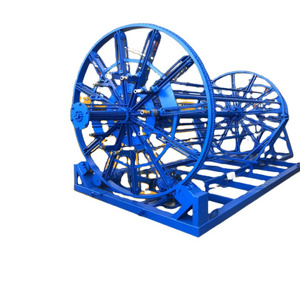

Concrete Pipe Making Machine

contact:Tina +86 18275773233(whatsApp)

* Roller hanging type concrete pipe machine is kind of machine to produce concrete pipes and pre-stress concrete pipe.

* It can make pipes with diameter from 300-1500mm and with length from 2000-5000mm. We can design many kinds of pipe joint,including flush joint(flat mouth type), groove joint, socket and spigot joint(socket and plug mouth type) ect.

* It can make pipes with diameter from 300-1500mm and with length from 2000-5000mm. We can design many kinds of pipe joint,including flush joint(flat mouth type), groove joint, socket and spigot joint(socket and plug mouth type) ect.

Machine Features

1. High efficiency, short production time, every pipe needs several minutes.

2. With hard dry casting concrete, high intensity & better strength;

3. No poluuted slurry discharge, environment friendly, also low noising;

4. Our CO2 Arc Welding and Plasma Cutting machine promise higher quality.

2. With hard dry casting concrete, high intensity & better strength;

3. No poluuted slurry discharge, environment friendly, also low noising;

4. Our CO2 Arc Welding and Plasma Cutting machine promise higher quality.

Concrete Pipes Application

All the concrete pipes are widely used in administrate drainage, agricultural field imigation, rood culvert and deep water well.

Specification

|

Type

|

HF800*2000

|

HF1200*2000

|

HF1650*2000

|

HF2000*2000

|

|

Pipe Diameter (mm)

|

300-800

|

8000-1200

|

1200-1650

|

1650-2000

|

|

Roller Diameter (mm)

|

127

|

216

|

273

|

325

|

|

Pipe Length (mm)

|

2000

|

2000

|

2000

|

2000

|

|

Motor Model

|

YCT225-4B

|

YCT1250-4B

|

YCT355-4A

|

YCT355-4B

|

|

Motor Power (KW)

|

15

|

18.5

|

55

|

75

|

|

Rolling Speed (r/m)

|

62-618

|

62-618

|

72-727

|

72-727

|

|

Machine Dimension (mm)

|

4100x2350x1600

|

4100x2350x1850

|

4550x3500x2500

|

4550x3500x2900

|

Packing & Delivery

To better ensure the safety of your goods, professional, environmentally friendly, convenient and efficient packaging services will be provided.

Our Services

Pre-sales Service

(1) Professional suggestions (raw material matching, machine selection, the condition of building factory,feasibility analysis for pipe machine production line).

(2) Device model choice (recommend the best machine according to the raw material, capacity and the size of pipe).

(3) Introduce the company file, product categories and production process.

Welcome to visit our factory and production line anytime.

Sale

(1) Update the production scheduling in time.

(2) Quality supervision.

(3) Product acceptance.

(4) Shipping on time.

After-sales Service

(1) Training how to instal the machine, training how to use the machine.

(2) Engineers available to service machinery overseas.

(3) Recall clients regularly, get feedback in time, keep well communication with each other.

(1) Professional suggestions (raw material matching, machine selection, the condition of building factory,feasibility analysis for pipe machine production line).

(2) Device model choice (recommend the best machine according to the raw material, capacity and the size of pipe).

(3) Introduce the company file, product categories and production process.

Welcome to visit our factory and production line anytime.

Sale

(1) Update the production scheduling in time.

(2) Quality supervision.

(3) Product acceptance.

(4) Shipping on time.

After-sales Service

(1) Training how to instal the machine, training how to use the machine.

(2) Engineers available to service machinery overseas.

(3) Recall clients regularly, get feedback in time, keep well communication with each other.

Hot Searches