- Product Details

- {{item.text}}

Quick Details

-

Rolling thinckness:

-

0.3-1mm

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

willing

-

Voltage:

-

380v 3Phase 50Hz

-

Dimension(L*W*H):

-

5m*1.3m*1.3m-15m*1.3m*1.4m

-

Weight:

-

3.2 kg

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Main motor power::

-

4kw

-

Hydraulic power::

-

3kw

-

Controller::

-

PLC

-

Roller driven type::

-

Chain transmission

Quick Details

-

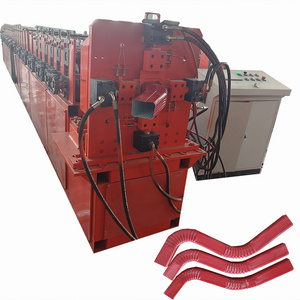

Type:

-

Tile Forming Machine

-

Tile Type:

-

Steel

-

Production Capacity:

-

10-12m/min

-

Rolling thinckness:

-

0.3-1mm

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

willing

-

Voltage:

-

380v 3Phase 50Hz

-

Dimension(L*W*H):

-

5m*1.3m*1.3m-15m*1.3m*1.4m

-

Weight:

-

3.2 kg

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Main motor power::

-

4kw

-

Hydraulic power::

-

3kw

-

Controller::

-

PLC

-

Roller driven type::

-

Chain transmission

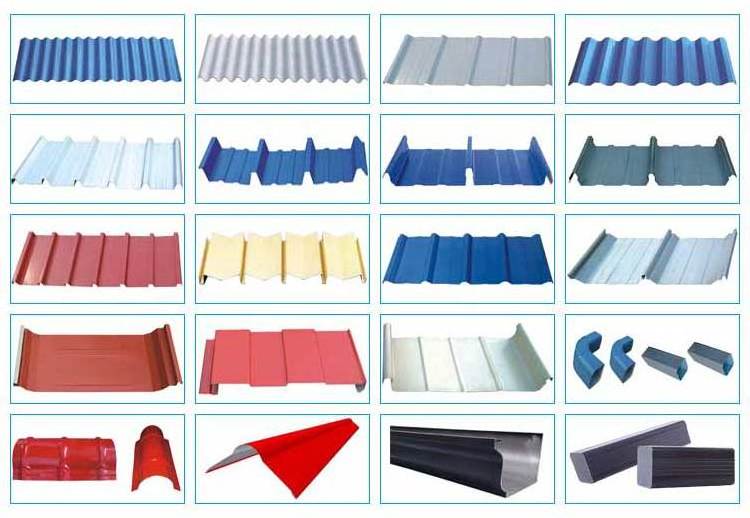

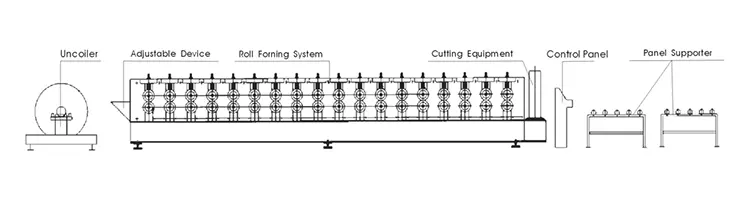

|

Product Name

|

|

Steel roof & wall forming machine

|

|

|

Material

|

Type

|

Pre-painted & galvanized steel coil

|

|

|

|

Thickness(mm)

|

0.3-0.7mm

|

|

|

|

Tield stress(Mpa)

|

Q235-345

|

|

|

Max.forming speed (m/min)

|

|

10-15m/min

|

|

|

Roller material

|

|

#45 steel with hard chrome treatment

|

|

|

Roller driven type

|

|

Chain transmission

|

|

|

Controller

|

|

PLC

|

|

|

Operation

|

|

Touch screen and button

|

|

|

Hydraulic system pressure(Mpa)

|

|

12

|

|

|

Main motor power(KW)

|

|

4

|

|

|

Hydraulic station motor power

|

|

3

|

|

|

Dimension (L*W*H)

|

|

about 8500*1500*1500mm

|

|

|

Weight (KG)

|

|

about 6000

|

|

Our Service:

- Provide Pre-sales Consultant & On-purchase service & After-sales service 24hr × 7days per week

- Give technical suggestion

- Test the machine before shipment

- Provide technical guidance relate to use the machine

- Supply one-year warranty period for the machine

- Provide the spare parts at cost price after warranty period

- Collect the feedback for the machine working

- Provide long-term technical assistance.

Q1: Are you manufacturer or trading company?

A1: We are manufacturer

Q2: Do you have overseas engineers?

A2: Yes, we not only provide overseas engineers, but also provide technical training.

Q3: Do you provide customized?

A3: Sure, we can design the equipment according to your request. We are professional sheet metal forming machine designer and manufacturer.

Q4: How does your factory do regarding quality control?

A4: There is no tolerance regarding quality control. Quality control complies with ISO 9001.every machine has to past testing running before it's packed for shipment.

Q5: How can I trust you that machines pasted testing running before shipping?

A5: 1) We record the testing video for your reference

2) We welcome you visit us and test machine by yourself in our factory.

Q6. Do you have after-sales support?

A6: Yes, we are happy to provide advice and we also have skilled technicians available to install or maintain for your in your place.

Q7:Can I visit you factory to check machines on-site? What Should I bring when I visit your factory?

A7: We are manufacturer, and we welcome customers to visit our factory. For special product design and develop, we request you bring a piece of testing material, you can test on our machines on-site.

Q8. What's your payment terms and delivery time?

A8: We prefer 30% as the deposit by T/T, 70% balance payment by T/T after your inspect the machine well and before delivery. Or irrevocable LC at sight is acceptable.

After we receive deposit, we will arrange production. delivery time is about 60-70 day.

Q9: How to visit your company?

A9: We can pick you up from Hangzhou airport. Or railway station Hangzhou or Hangzhou East.