Metal chain conveyor sink into ground design. Easily transport PET big bottle bricks into de-baler machine. BOXIN De-baler machine with high efficiency and horizontal design. Optional virtical design. For different materials can choose double shaft or four shaft design. This hotizontal de-baler machine suitable for high capacity big baled bottle bricks.

- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

BOXIN

-

Application:

-

waste pet recycle machine

-

Production Capacity (kg/h):

-

500 - 1500

-

Voltage:

-

380V/50Hz

-

Dimension(L*W*H):

-

65*6*5m

-

Power (kW):

-

210-260

-

Weight (T):

-

55

-

Name:

-

plastic bottle recycling machine

-

Final product:

-

Clean PET Flakes

-

Keywords:

-

plastic recycling machine

-

Raw material:

-

PET Waste Plastic Bottle

-

Capacity:

-

500-5000kg/h

-

Usage:

-

Bottle Crushing Washing Drying

-

Function:

-

Make Recycle Plastic Granules

-

Hot search:

-

pet bottle recycling line

-

Type:

-

Plastic Recycling Granulating

-

Related products:

-

PE PP Waste Film Recycling Washing Line

Quick Details

-

Machine Type:

-

PP PE Bottle Washing Line

-

Max.Production Capacity (kg/h):

-

1500

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

BOXIN

-

Application:

-

waste pet recycle machine

-

Production Capacity (kg/h):

-

500 - 1500

-

Voltage:

-

380V/50Hz

-

Dimension(L*W*H):

-

65*6*5m

-

Power (kW):

-

210-260

-

Weight (T):

-

55

-

Name:

-

plastic bottle recycling machine

-

Final product:

-

Clean PET Flakes

-

Keywords:

-

plastic recycling machine

-

Raw material:

-

PET Waste Plastic Bottle

-

Capacity:

-

500-5000kg/h

-

Usage:

-

Bottle Crushing Washing Drying

-

Function:

-

Make Recycle Plastic Granules

-

Hot search:

-

pet bottle recycling line

-

Type:

-

Plastic Recycling Granulating

-

Related products:

-

PE PP Waste Film Recycling Washing Line

Product Description

This is BOXIN BXA series PET bottle crushing washing drying recycling line. Including sorting, size reduction, metal removing, cold and hot washing, high efficiency friction washing and drying modular. Which can remove ferrous and nonferrous metals, sand, oil, glue, paper and many other different contaminants efficiency.

mainly used to recycling the waste PET bottles, water bottles,cola bottles, PET sheet and PET packing containers. The Recycled waste cola bottle PET recycling machine can easily remove the labels, caps, rings, glue, dirties and other impurities, finally you will get ideal PET flakes. All your requirements of the Recycled waste cola bottle PET recycling machine will be customized.

The whole line is fully automatic and it has characteristics of high efficiency, low noise and easy operation.the humidity of final output could be within 1%. It adopts hot water washing to get good quality. Various output capacities can be chosen:

500kg/h, 1000kg/h, 1500kg/h, 2000kg/h.3000kg/h,5000kh/h

.The waste dirty material go through delabelling, crushing, washing, drying, and collecting process will turn to be clean flakes for reuse.

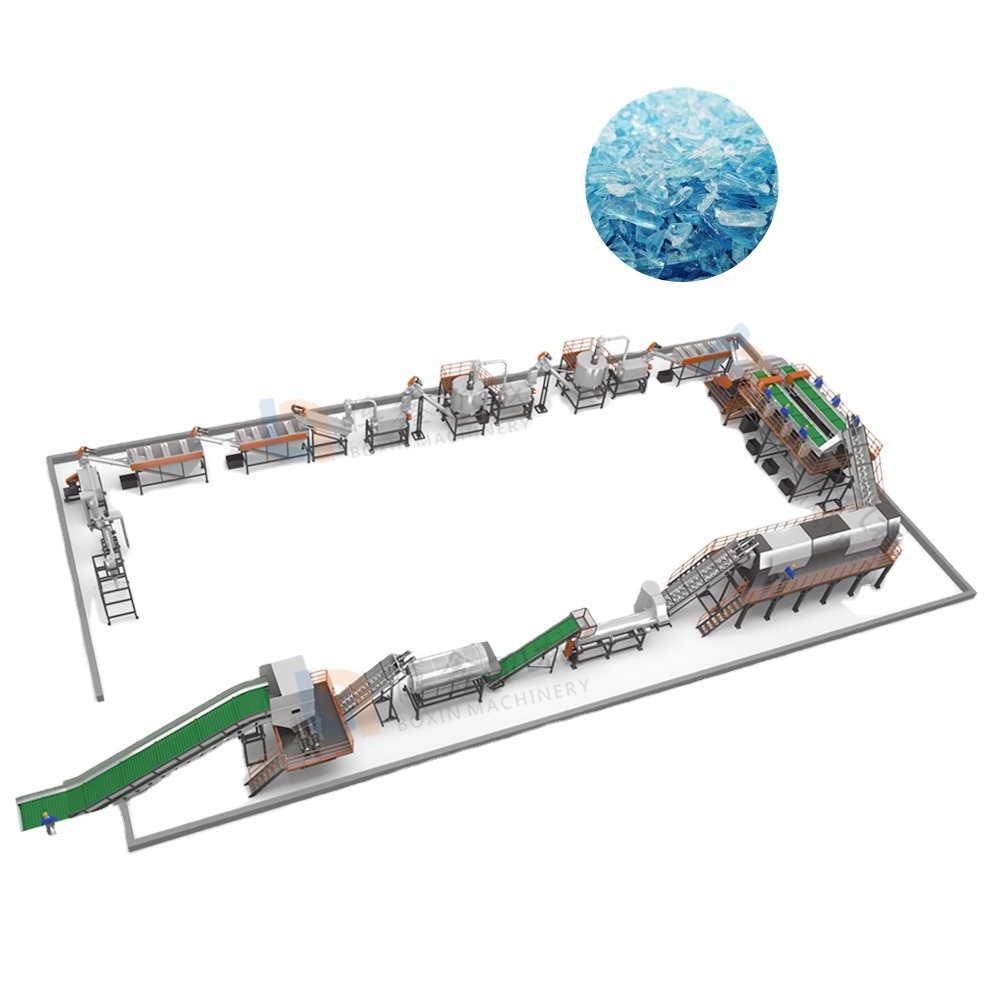

This pet bottle washing machine can be displayed "L" or "U" shape according to clients' workshop.

We can also customize the washing line components according to client's material and product requirement.

This pet bottle washing machine can be displayed "L" or "U" shape according to clients' workshop.

We can also customize the washing line components according to client's material and product requirement.

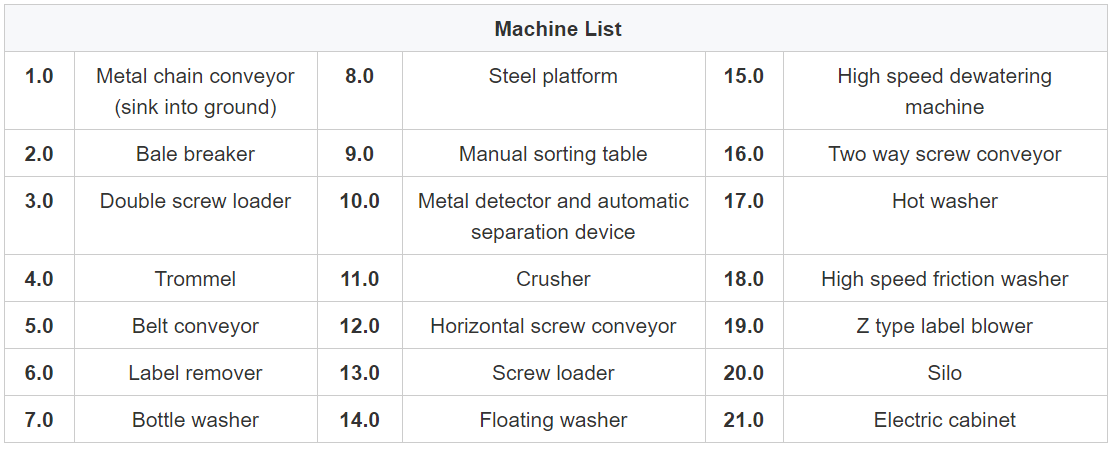

Technical Parameter

|

Model

|

BXA-500

|

BXA-1000

|

BXA-2000

|

BXA-3000

|

|

Input capacity

|

500kg/h

|

1000 kg/h

|

2000 kg/h

|

3000kg/h

|

|

Workshop(M*M*M)

|

42 (L)×10(W)×6(H)

|

55(L)×15(W)×6(H)

|

70(L)×18(W)×6(H)

|

70(L)×30(W)×7(H)

|

|

Ancillary staff

|

6

|

8

|

12

|

12

|

|

Installation power

|

156KW

|

307KW

|

420KW

|

652KW

|

|

Water consumption

|

2Ton/h

|

3.5Ton/h

|

5 Ton/h

|

18Ton first time

then 2-3Ton/h

|

|

Final product

|

Moisture: max 0.7%

Bulk density: 0.3G/CM3 Particle size: 14-18mm Metal content: max.20ppm Floatable contamination: less than 200ppm Total impurity: 320ppm |

Moisture: max 0.7%

Bulk density: 0.3G/CM3 Particle size: 14-18mm Metal content: max. 20oom Floatable contamination: less than 200ppm Total impurity: 320ppm |

Moisture: max 0.7%

Bulk density: 0.3G/CM3 Particle size: 14-18mm Metal content: Max. 20ppm Floatable contamination: less than 200ppm Total impurity: 320ppm |

Moisture: max 0.7%

Bulk density: 0.3G/CM3 Particle size: 14-18mm Metal content: Max. 20ppm Floatable contamination: less than 200ppm Total impurity: 320ppm |

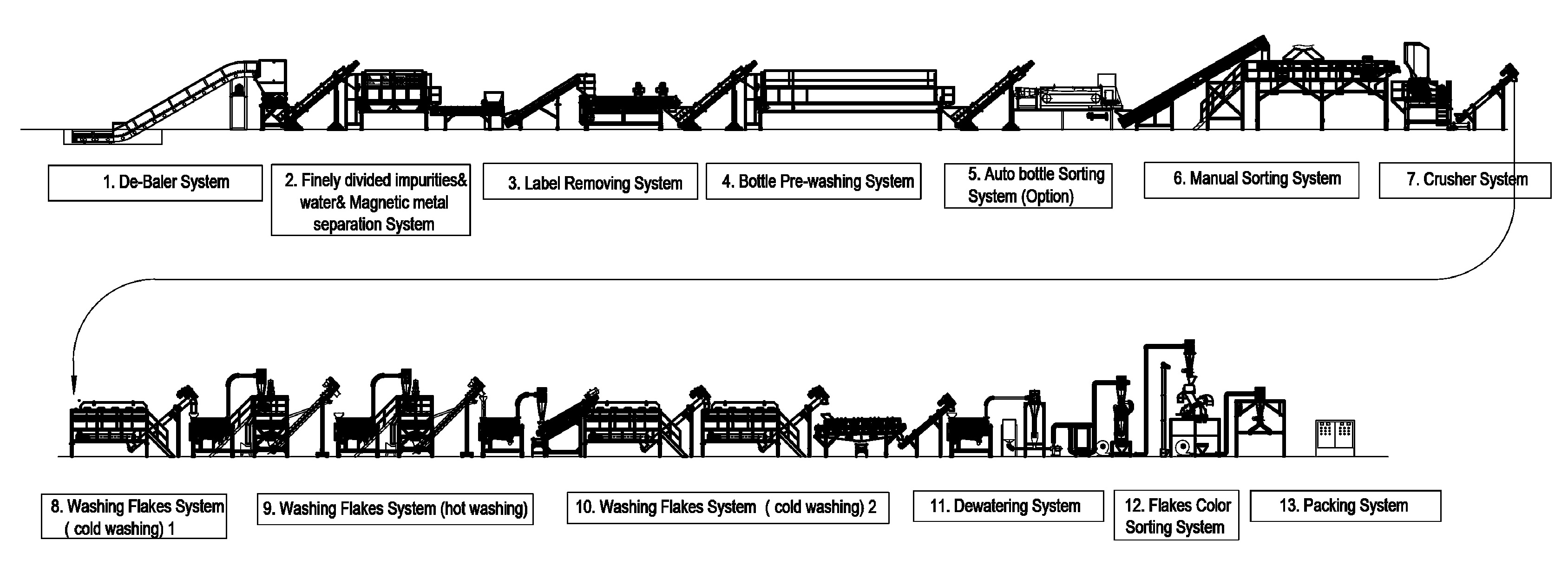

De-baler/unpacking system

Trommel

Separate various impurities, such as sand, stone, metal, etc. The mesh size can be designed according to customers requirements.

Label remover and Manual sorting table

Label remover can separate bottle labels and caps. High precision metal detector removes all kinds of metals. Non-stop design.

Automatic metal sorting, by turning the plate automatically remove the bottles with metals.

Crushing system

BOXIN crushers with durable D2 blades. Hydraulic opening method. V-shaped arrangement of the rotor knives. The chamber with wear-proof design. Screen size can be designed according to customers requirements.

Float s

edimentation separation tank

High pressure underwater cleaning design. Remove small caps, labels, and other impurities. The rinsing roller is individually controlled by the reducer. Main machine body SUS304

Steam washing station

Add chemicals and hot wash to remove oil, impurities and labels. Double layer design with SUS304. Steam boiler to produce steam, aand the water temperature reaches 90-95℃. This device can effectively remove impurities and separate labels and bottle caps, especially for glue, oil. So the cleanliness of bottle flakes is greatly improved.

Packing system

This packing system including with pipe drying system, zig-zag label blowerv and double outlet silo. Separate light materials like labels, dust, etc. from clean PET bottle flakes. Silo two outlets design. With 4 or 6 cylinders which can help storage more flakes.

1.Final products have good quality. When process PET bottle, final products humidity below 0.7%, impurities100ppm,PVC label content 100ppm.

2.Parts which contact material use SUS304 stainless steel, thickness more than 3mm, ensure long service lift time and no second pollution to flakes.

3.World famous brand components applied on the production line- NSK bearing, Siemens contactor, Omron temperature, FUJI inverter, Siemens PLC control etc.

4. Friendly control system (PLC integrated & separated control on each machine) and Touch screen panel, easy for operation, monitor and emergency stop.

5.The whole production equipment is researched, design and manufactured by our company with CE certification, ISO9001

certification; it can be designed based on the dirty flakes, and make sure of the quality of the final products.

2.Parts which contact material use SUS304 stainless steel, thickness more than 3mm, ensure long service lift time and no second pollution to flakes.

3.World famous brand components applied on the production line- NSK bearing, Siemens contactor, Omron temperature, FUJI inverter, Siemens PLC control etc.

4. Friendly control system (PLC integrated & separated control on each machine) and Touch screen panel, easy for operation, monitor and emergency stop.

5.The whole production equipment is researched, design and manufactured by our company with CE certification, ISO9001

certification; it can be designed based on the dirty flakes, and make sure of the quality of the final products.

Hot Searches