- Product Details

- {{item.text}}

Quick Details

-

Application:

-

plastic extruder machine replacement parts

-

Screw Material:

-

W6Mo5Cr4V2 or 38CrMoAl

-

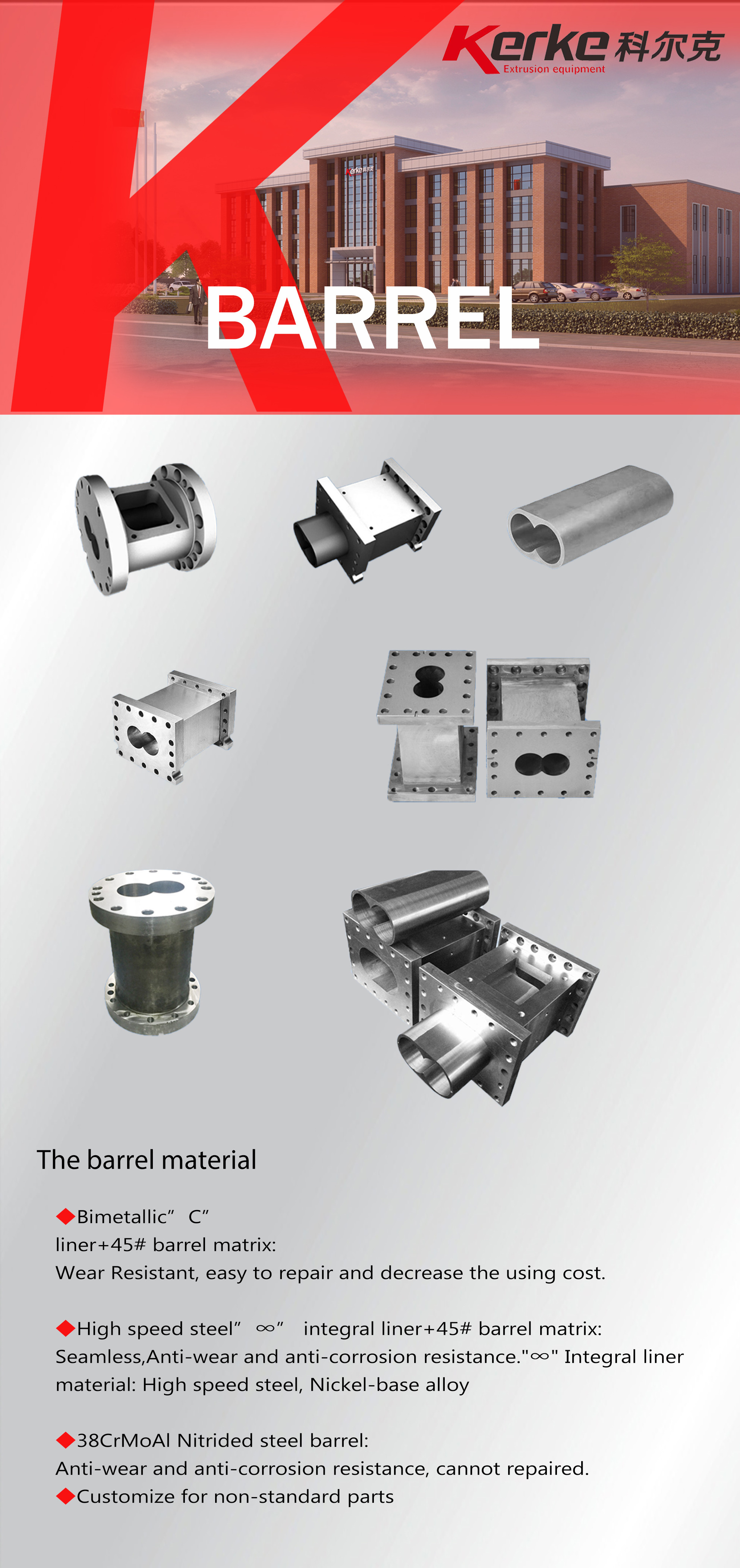

Barrel:

-

45# steel matrix

Quick Details

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

KERKE

-

Weight (KG):

-

2

-

Application:

-

plastic extruder machine replacement parts

-

Screw Material:

-

W6Mo5Cr4V2 or 38CrMoAl

-

Barrel:

-

45# steel matrix

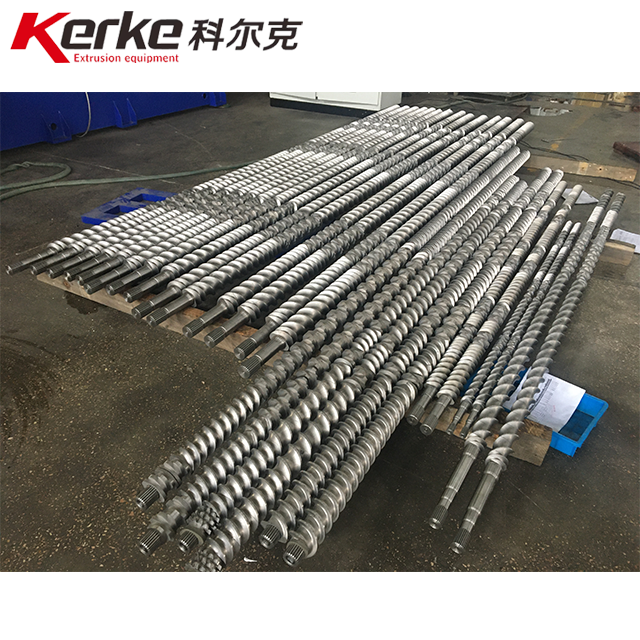

W6Mo5Cr4V2 high quality twin screw extruder screw and barrel

| —PRODUCT PARAMETERS— |

| —MACHINE PROCESS— |

| —USER-DEFINED ATTRIBU— |

Application: for single/twin screw extruder

Type: machine parts

Plastic processed: polyolefins, wood composites, PVC

Brand name:Kerke

Model number: customizable

Material: W6Mo5Cr4V2/38CrMoALA /440C etc

Package: wooden case

Delivery time: 3 0 working days

Hardness : HRC 58-62

Certification: CE& BV&TUV

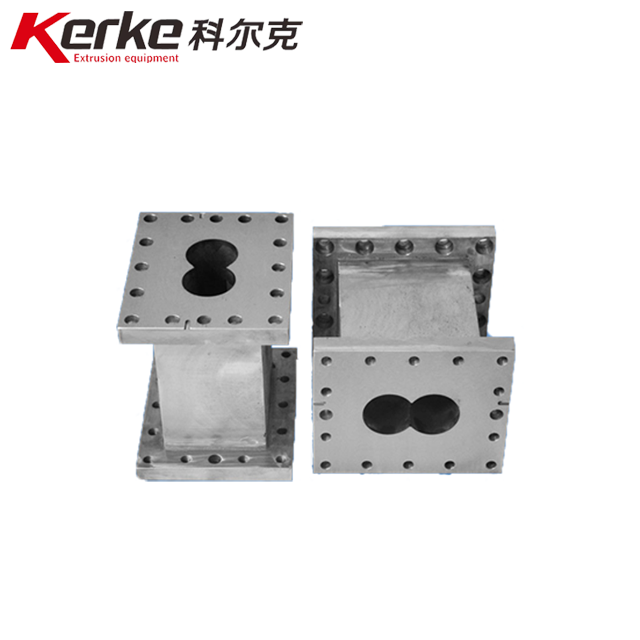

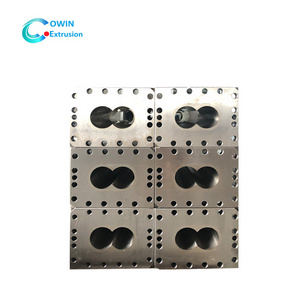

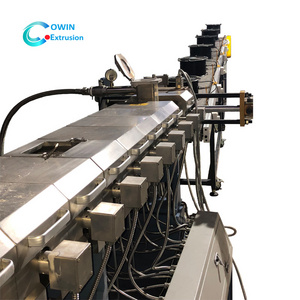

Barrel: 45 steel, 38CrMoAl nitrided, etc

Inside liner: W6Mo5Cr4V2, C12MoV, tungusten carbide, etc

Treatment : tempering/nitrogen, etc

Application: for twin/single screw extruder

Type: machine parts

Material: 45# steel

Surface treatment:bimetallic execution

Brand name:Kerke

Model number: customizable

Package: wooden case

Delivery time: 20 working days

HRC: 58-62

Certification: CE& BV&TUV

| —DESCRIPTION— |

Twin screw extruder screw element:

· convenient interchangeability by agile combination.

· fulfill efficient self-cleaning, transmission, compounding, pressure-forming, etc.

· made of high tool speed W6Mo5Cr4V2, or anti-corrosion steel 38CrMoAlA by special treatment.

Assembled together, they will become twin screw which are essential and key part of extruders for material to

transmission, shearing and plasticization.

Designed by modular principle.

Precise processed, agile combination

Self-cleaning,transmission,compounding

barrel: 45# steel barrel body, inside line is made of bi-metal alloy.

building blocks barrel and screw can adjust different materials

By means of the replaceable screw barrel sections, the processing sections is devoted into individual zones. The barrels are heated electrically. In addition, the barrels are provided with longitudinal bores for cooling with water. Uniform temperature distribution, namely on the circumference of the eight-shaped barrel bore, is achieved by a reverse force-flow temperature control circuit. Connections of pipes for temperature control are in groove-tongue design to balance alternating thermal stress and avoid leakage.