- Product Details

- {{item.text}}

Quick Details

-

Filling Accuracy:

-

±0.1%

-

Voltage:

-

Customizable

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

Honor Machine

-

Dimension(L*W*H):

-

Customizable

-

Weight:

-

5500 KG

-

Product name:

-

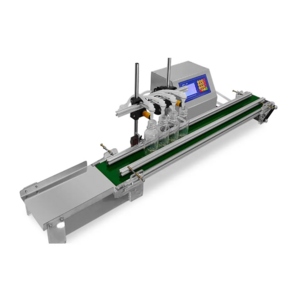

Juice bottling machine

-

Capacity:

-

500-18000BPH

-

Function:

-

Filling Labeling Packing

-

Suitable bottle:

-

PET/Glass bottle

-

Bottle size:

-

0.1-2L

-

Machine material:

-

SUS304/316

-

Filling Liquid:

-

Juice

-

Filling system:

-

Hot filling type

-

Control system:

-

PLC (SIEMENS)

-

After-sales Service Provided:

-

2 years

Quick Details

-

Machinery Capacity:

-

4000BPH, 8000BPH, 12000BPH, 6000BPH, 20000BPH, 16000BPH, 2000BPH

-

Packaging Material:

-

Wood

-

Filling Material:

-

Beer, Milk, Water, Oil, Juice, Powder

-

Filling Accuracy:

-

±0.1%

-

Voltage:

-

Customizable

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

Honor Machine

-

Dimension(L*W*H):

-

Customizable

-

Weight:

-

5500 KG

-

Product name:

-

Juice bottling machine

-

Capacity:

-

500-18000BPH

-

Function:

-

Filling Labeling Packing

-

Suitable bottle:

-

PET/Glass bottle

-

Bottle size:

-

0.1-2L

-

Machine material:

-

SUS304/316

-

Filling Liquid:

-

Juice

-

Filling system:

-

Hot filling type

-

Control system:

-

PLC (SIEMENS)

-

After-sales Service Provided:

-

2 years

Product Description

RCGF series juice filling machine-Washing filling capping 3-in-1

This series of equipment is used for hot filling production of tea drinks, fruit juice drinks and other products. This series is a combination of sterilization, filling and sealing. the design is scientific and reasonable, so operate is simple. It is the preferred equipment for hot-filling drinks.

The filling temperature of this machine is 55-95℃ hot filling, It adopts suspension air conveyor. When change the bottle,It only needs to adjust the conveying width, which is more efficient and labor-saving. Filling action is smooth, fast, high precision, reliable sealing, low material loss and other functions, avoid secondary pollution of materials effectively .

It adopts advanced technologies such as human-machine interface touch control system, PLC computer control, frequency converter control, etc. It has high degree of automation and easy operation.

Different filling capacities

14-12-5 Bottle Water Filling Line Capacity:1000-3000 bottles per hour.

18-18-6 Bottle Water Filling Line Capacity:3000-5000 bottles per hour.

24-24-8 Bottle Water Filling Line Capacity:6000-9000 bottles per hour.

32-32-10 Bottle Water Filling Line Capacity:9000-13000 bottles per hour.

40-40-12 Bottle Water Filling Line Capacity:14000-18000 bottles per hour.

Specification

|

Model

|

RCGF14-14-5

|

CGF14-12-5

|

RCGF18-18-6

|

RCGF24-24-8

|

RCGF32-32-10

|

RCGF40-40-10

|

|||||

|

Capacity(500ml/bottle/h)

|

1000-3000

|

2000-4000

|

3000-5000

|

6000-9000

|

9000-13000

|

14000-18000

|

|||||

|

Suitable bottle shape

|

Round bottle or square bottle

|

|

|

|

|

|

|||||

|

Filling precision

|

≤+5mm(liquid level)

|

|

|

|

|

|

|||||

|

Bottle height(mm)

|

160-320

|

|

|

|

|

|

|||||

|

Filling pressure(Mpa)

|

0.15-0.35

|

|

|

|

|

|

|||||

|

Filling temperature(℃)

|

55-85

|

|

|

|

|

|

|||||

|

Total power(kw)

|

4.4

|

4.5

|

4.8

|

5.5

|

8

|

9

|

|||||

|

Overall dimensions(mm)

|

2300*1800*2200

|

2400*1880*2000

|

2600*2000*2200

|

3050*2300*2300

|

3650*2800*2400

|

4000*3150*2500

|

|||||

|

Weight(kg)

|

3200

|

3050

|

4500

|

6500

|

7500

|

8600

|

|||||

Details Images

1, Water Treatment System

Simple operation / Less maintenance / Lower power co

sumption

Water treatment system refers to the measures taken to make the water quality meet certain use standards. The physical characteristics of water, such as temperature, color, transparency, odor and taste, are filtered or treated so that water can be used directly for drinking or other purposes.

2,Processing system

Complete juice processing system is not only can be suitable for common products ,but also can satisfy special requirements of customers ,for example concentrated juice, fresh juice, tea, coffee or flavor milk, cream or high viscosity products containing fiber and large pulp granules. it included high-shear emulsifying tank, plate heat exchanger, double filter, mixing tank, UHT sterilizer, homogenizer machine, buffer tank, hot water system, hot water tank and CIP cleaning system.

3,Washing Filling Capping 3-in-1 Machine

This machine is mainly

used for hot filling production of tea drinks, fruit juice drinks and other products. This series is a combination of sterilization, filling and sealing. the design is scientific and reasonable, so operate is simple. It is the preferred equipment for hot-filling drinks.

4,Labeling & Packing Machine

As customer request and market demand ,we provide the suitable solution for the final product package ,

We have various kinds of options .Labeling machine have the PVC sleeve label ,BOPP hot glue label,Adhesive stick label ,Wet glue label ,and packing machine have the film shrink machine and carton box package.

5,Bottle Blowing Machine

1)Excellent Mechanical Strength, impact-resisting, and non-craking.

2)Bottle mouth and thread are of precise measurement.

3)Plastic Medicine Bottle's safe thread can be molding directly.

4)The size and weight of the product can calculate and design clearly and meet the requirement of the design without any deviation.

5)The surface of the bottle mouth, neck and the body is good luster and smoothness, the standard of bottle body is unity.

6)The joint seam on the bottle body is smooth, no scrap rubber.

Turnkey Solution

We are not only a filling equipment manufacturer, but also design and build factories, equipment layout, circuit layout and equipment operation schemes. Our equipment is designed carefully, easy to use and easy to manage. Whether you need a machine or a complete filling and packaging system, we have rich experience to ensure the successful completion of your project.

Hot Searches