- Product Details

- {{item.text}}

Quick Details

-

Table Travel (Z) (mm):

-

35 mm

-

Travel (W-axis) (mm):

-

1200 mm

-

Range of Spindle Speed(r.p.m):

-

1000 r.p.m

-

Spindle Motor Power(kW):

-

0.4

-

Production Capacity:

-

20-1000rpm

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

TIMAC TIMEWAY

-

Voltage:

-

as request

-

Weight (T):

-

600 T

-

machine tool:

-

gas valve seat boring machine

-

Power:

-

0.4kw

-

After-sales Service Provided:

-

Online support

-

After Warranty Service:

-

Online support

-

Local Service Location:

-

Russia

Quick Details

-

Table Size (mm):

-

Other

-

Table Travel (X) (mm):

-

950 mm

-

Table Travel (Y) (mm):

-

500 mm

-

Table Travel (Z) (mm):

-

35 mm

-

Travel (W-axis) (mm):

-

1200 mm

-

Range of Spindle Speed(r.p.m):

-

1000 r.p.m

-

Spindle Motor Power(kW):

-

0.4

-

Production Capacity:

-

20-1000rpm

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

TIMAC TIMEWAY

-

Voltage:

-

as request

-

Weight (T):

-

600 T

-

machine tool:

-

gas valve seat boring machine

-

Power:

-

0.4kw

-

After-sales Service Provided:

-

Online support

-

After Warranty Service:

-

Online support

-

Local Service Location:

-

Russia

Product Description

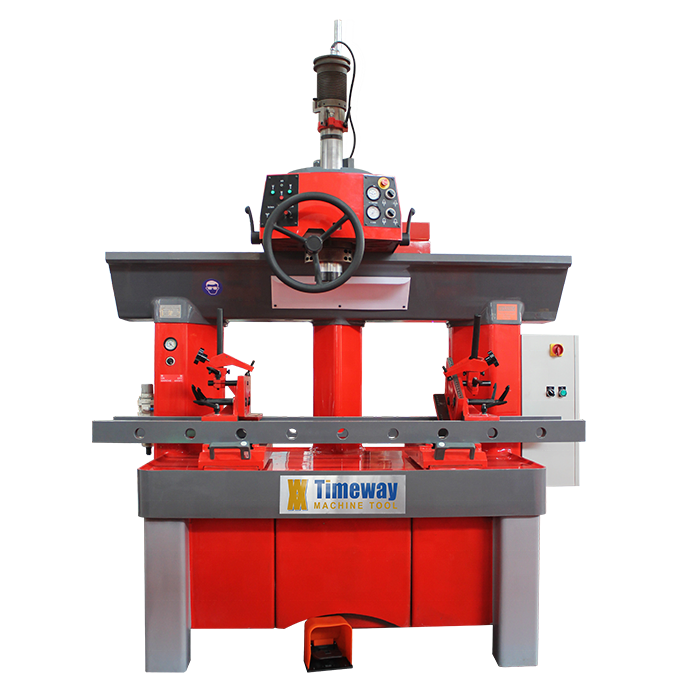

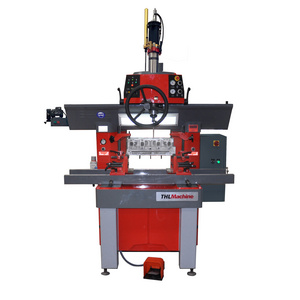

valve seat boring machine

feature

* This machine is suitable for repairing the valve seat of automobiles, motorcycle, tractor and other engines.

* It also can be used to drilling and boring etc.

* The machine features are air floating, vacuum clamping, high positing precision, easy operation.

Specification

|

Specification

|

TD60

|

|

Max. travel of principal axis sleeve

|

200mm

|

|

Spindle speeds

|

20-1000rpm

|

|

Boring rang

|

Φ20-Φ60mm

|

|

Spindle swing angle

|

5°

|

|

Spindle cross travel

|

950mm

|

|

Spindle longitudinal travel

|

35mm

|

|

Ball seat move

|

5mm

|

|

Angle of clamping device swing

|

+50°:-45°

|

|

Spindle motor power

|

0.4kw

|

|

Air supply

|

0.6-0.7Mpa;300L/min

|

|

Max. Size of cylinder cap for repairing

|

1200/500/300mm(L/W/H)

|

Client feedback

Our Services

1. Free replacing parts available in the warranty period.

Cost price replacing parts available beyond the warranty period.

2. Quick action and reply for the technical questions at any time in the whole life of the machine.

3. Overseas after service center available in some region.

4. Engineer overseas service available on the requirement of customer(relative cost born by customer).

Hot Searches