- Product Details

- {{item.text}}

Quick Details

-

Power:

-

120000

-

Weight (KG):

-

13000

-

Commodity:

-

flat angle bar hot rolling mill machine

-

Raw material:

-

Steel Scraps/Billets/old rebar

-

Advantages:

-

Large Output, High Efficiency

-

Final product:

-

Deformed Rebar/wire rod/flat bar/angle bar etc.

-

Capacity:

-

5-35 t/hour

-

After sales service provided:

-

Video technical support, Online support, Spare parts, etc

-

Certification:

-

CE

-

Mill:

-

Rough mill with continuous mill

-

Rolling type:

-

Automatic

-

After Warranty Service:

-

Long lifetime technical support

Quick Details

-

Place of Origin:

-

China

-

Brand Name:

-

HTGP

-

Voltage:

-

380v

-

Power:

-

120000

-

Weight (KG):

-

13000

-

Commodity:

-

flat angle bar hot rolling mill machine

-

Raw material:

-

Steel Scraps/Billets/old rebar

-

Advantages:

-

Large Output, High Efficiency

-

Final product:

-

Deformed Rebar/wire rod/flat bar/angle bar etc.

-

Capacity:

-

5-35 t/hour

-

After sales service provided:

-

Video technical support, Online support, Spare parts, etc

-

Certification:

-

CE

-

Mill:

-

Rough mill with continuous mill

-

Rolling type:

-

Automatic

-

After Warranty Service:

-

Long lifetime technical support

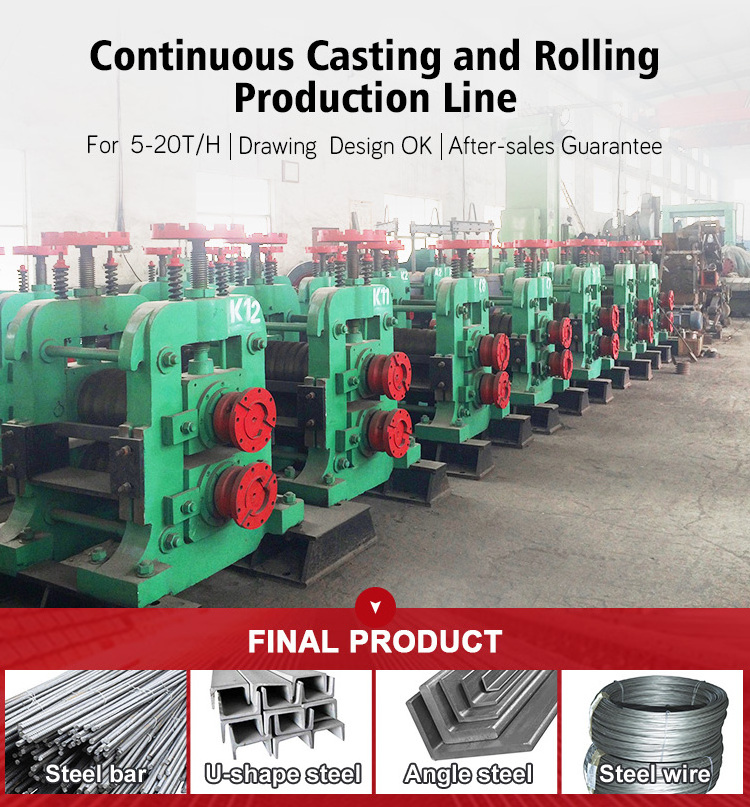

Steel rebar production line tmt bar iron rod hot rolling mill making machine flat angle iron bar automatic manufacturing machine

Product Description

1. The continuous rolling mill is an advanced method which can improve labor productivity and rolling type, mainly used in iron and steel plants to produce section bar, wire rod, steel bar, channel steel, flat bars, steel plates and other products. The raw material is steel scrap or billet (40-120mm).

2. The continuous casting and rolling production Line generally suitable for capacity of 5- 20t/h.

3. The diameter of the steel bar of the final product: 6.5-32mm, the length: 3000-12000mm.

2. The continuous casting and rolling production Line generally suitable for capacity of 5- 20t/h.

3. The diameter of the steel bar of the final product: 6.5-32mm, the length: 3000-12000mm.

Customer site

1, By using metallurgical heat energy of continuous casting blanks, 30% of energy consumption can be saved.

2, Simplify the production process, reduce the plant area of factory and save the cost of infrastructure construction.

3, Greatly shorten the production cycle, improve the quality of products

2, Simplify the production process, reduce the plant area of factory and save the cost of infrastructure construction.

3, Greatly shorten the production cycle, improve the quality of products

Product Advantages

1, Provide overall solution and after-sales guarantee

2, Provide plant design, proposal, manufacturing, shipping, installation and commissioning services

3, Provide factory building design, overall equipment layout, rolling mill process design, electrical circuit layout and other services.

4, Dispatch technicians to provide installation services after the machine arrives until the customer is satisfied

5, Long-term technical support, long-term machine warranty

2, Provide plant design, proposal, manufacturing, shipping, installation and commissioning services

3, Provide factory building design, overall equipment layout, rolling mill process design, electrical circuit layout and other services.

4, Dispatch technicians to provide installation services after the machine arrives until the customer is satisfied

5, Long-term technical support, long-term machine warranty

|

Specification and Technical Parameter

|

|

|

|

|

||||

|

Capacity(T/Hour)

|

Working hours(Year)

|

Electricity consumption

|

Feeding Section

|

Rolling Specification

|

||||

|

5

|

2400

|

5MW

|

60*60mm

|

Φ8-16mm

|

||||

|

8

|

2400

|

8.5MW

|

70*70mm

|

Φ8-16mm

|

||||

|

10

|

3600

|

9.5MW

|

90*90mm

|

Φ8-32mm

|

||||

|

15

|

3600

|

10MW

|

120*120mm

|

Φ8-32mm

|

||||

|

16

|

6000

|

15MW

|

120*120mm

|

Φ6.5-32mm

|

||||

|

30

|

6000

|

26MW

|

150*150mm

|

Φ6.5-32mm

|

||||

Recommend Products

Why Choose Us

Certifications

FAQ

1: Are you the Manufacturer or a trading company?

We are direct manufacturer specialized in produce in machinery for 15 years.Our factory located in high industry zone,Luoyang city,henan province,where is the biggest industry machinery manufacturing base in china.

2: Why should we choose Hongteng?How do you ensure the quality?

We have professional research staff and strict in Production,inspection and debugging and package process.We always insist on supply good pre-sales,order following,after sell service for our customers.

We have professional QC person inspect machinery production.After production finished,all machines will be testing & debugging carefully before shipment.

3: Which kind of power supply do you supply? Electricity or gas?

Electricity, natural gas and LPG

4: How can I trust your company and machine?

Our factory have been in producing machinery for around 15 years ,our machine have exported to East Asia, South Asia, the middle East Asia, Africa etc. areas and have a good feedback with no complaints.

Welcome to visit us,and have a face to face negotiation.

5: How do you control the quality?

We have QC team comply with TQM to ensure the quality. Each step is in compliance to the standards. At the same time, we will take photos and shoot video for you if you need.

6: Which county do you exported to ?

We have already exported our machines to many famous company in many countries, such as

Vietnam, Indonesia, Myanmar, Qatar, Ukraine etc. Welcome customers to visit our factory.

7: How about your after sales service?

After customers get machines,We will send our engineers to customer's workshop.We will supply installation & debugging & training service for customers till machine normal production.

We are direct manufacturer specialized in produce in machinery for 15 years.Our factory located in high industry zone,Luoyang city,henan province,where is the biggest industry machinery manufacturing base in china.

2: Why should we choose Hongteng?How do you ensure the quality?

We have professional research staff and strict in Production,inspection and debugging and package process.We always insist on supply good pre-sales,order following,after sell service for our customers.

We have professional QC person inspect machinery production.After production finished,all machines will be testing & debugging carefully before shipment.

3: Which kind of power supply do you supply? Electricity or gas?

Electricity, natural gas and LPG

4: How can I trust your company and machine?

Our factory have been in producing machinery for around 15 years ,our machine have exported to East Asia, South Asia, the middle East Asia, Africa etc. areas and have a good feedback with no complaints.

Welcome to visit us,and have a face to face negotiation.

5: How do you control the quality?

We have QC team comply with TQM to ensure the quality. Each step is in compliance to the standards. At the same time, we will take photos and shoot video for you if you need.

6: Which county do you exported to ?

We have already exported our machines to many famous company in many countries, such as

Vietnam, Indonesia, Myanmar, Qatar, Ukraine etc. Welcome customers to visit our factory.

7: How about your after sales service?

After customers get machines,We will send our engineers to customer's workshop.We will supply installation & debugging & training service for customers till machine normal production.

Hot Searches