The raw materials used in needle punched geotextiles, such as polyester and polypropylene, are acid and alkali resistant, non corrosive, and non insect resistant; The product has good water permeability; Lightweight and convenient for construction.

- Product Details

- {{item.text}}

Quick Details

-

Application:

-

Outdoor

-

Design Style:

-

Industrial

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

huabo

-

Model Number:

-

T-0.9

-

Type:

-

Non-Woven Geotextiles

-

Product name:

-

Geotextile Non Woven Fabrics

-

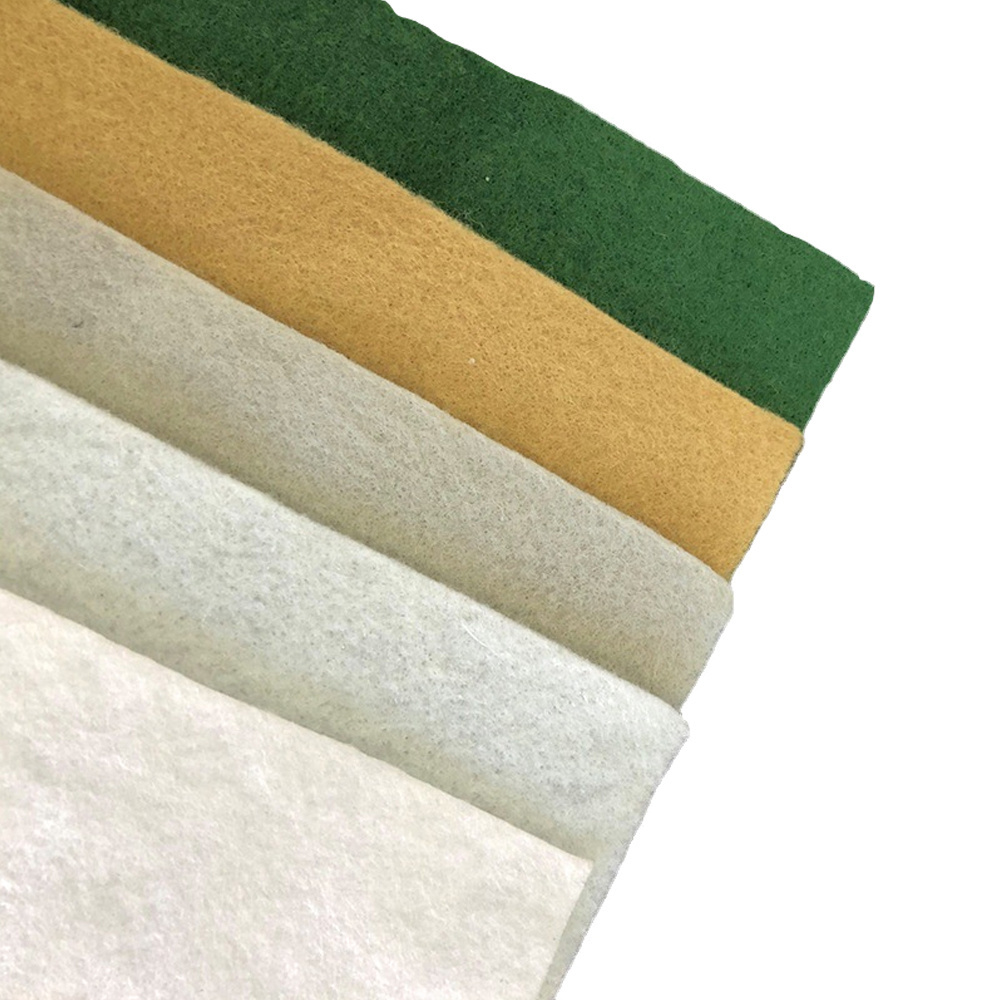

Color:

-

Black

-

Material:

-

100% Polyester

-

Keyword:

-

Nonwoven Needle Punched Geotextile

-

Certificate:

-

ISO9001/ISO14001

-

Function:

-

Slop Protection

-

Package:

-

Woven Bags

-

Feature:

-

Eco-Friendly

-

Usage:

-

Ecological Slope Protection System

-

Packing:

-

Roll Packing

Quick Details

-

Warranty:

-

3 years

-

After-sale Service:

-

Online technical support, Onsite Installation, Onsite Training, Onsite Inspection, Free spare parts, Return and Replacement

-

Project Solution Capability:

-

graphic design, 3D model design, total solution for projects, Cross Categories Consolidation

-

Application:

-

Outdoor

-

Design Style:

-

Industrial

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

huabo

-

Model Number:

-

T-0.9

-

Type:

-

Non-Woven Geotextiles

-

Product name:

-

Geotextile Non Woven Fabrics

-

Color:

-

Black

-

Material:

-

100% Polyester

-

Keyword:

-

Nonwoven Needle Punched Geotextile

-

Certificate:

-

ISO9001/ISO14001

-

Function:

-

Slop Protection

-

Package:

-

Woven Bags

-

Feature:

-

Eco-Friendly

-

Usage:

-

Ecological Slope Protection System

-

Packing:

-

Roll Packing

Products Description

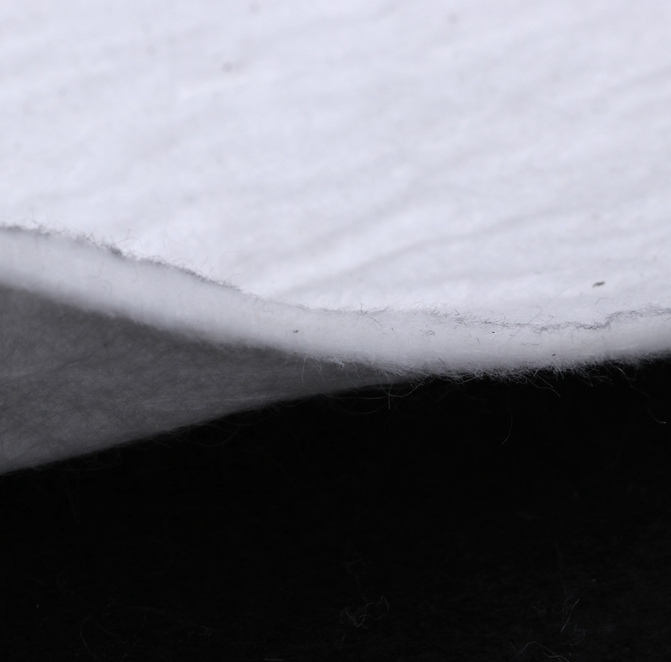

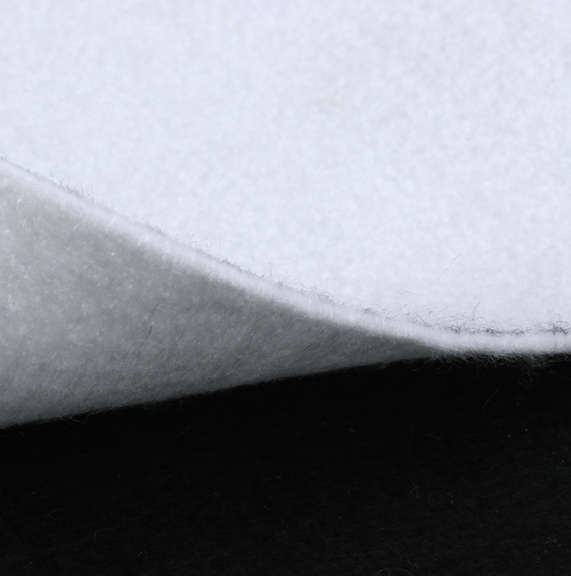

Needle punched

non-woven geotextile

Needle punched nonwoven geotextile is mainly a permeable geotextile made from high-quality polyester and polypropylene fibers as raw materials through needle punching, polyester filament mesh formation, and consolidation methods.

|

Product specifications and performance parameters(GB/T 17638-1998)

|

|

|

|

|

|

|

|

|

|

|||||||||

|

Item

|

100

|

150

|

200

|

250

|

300

|

350

|

400

|

450

|

500

|

|||||||||

|

Mass deviation

per unit area

|

-8

|

-8

|

-8

|

-8

|

-7

|

-7

|

-7

|

-7

|

-6

|

|||||||||

|

Thickness

(mm≥)

|

0.9

|

1.3

|

1.7

|

2.1

|

2.4

|

2.7

|

3

|

3.3

|

3.6

|

|||||||||

|

Width tolerance

(%)

|

0.5

|

4.5

|

6.5

|

8

|

9.5

|

11

|

12.5

|

14

|

16

|

|||||||||

|

Breaking strength

(KN/m)

|

2.5

|

4.5

|

6.5

|

8

|

9.5

|

11

|

12.5

|

14

|

16

|

|||||||||

|

Breaking elongation

(%)

|

25 - 100

|

0.6

|

0.9

|

1.2

|

1.5

|

1.8

|

2.1

|

2.4

|

2.7

|

|||||||||

|

CBR burst strength

(KN≥)

|

0.3

|

0.6

|

0.9

|

1.2

|

1.5

|

1.8

|

2.1

|

2.4

|

2.7

|

|||||||||

|

EOS O90

(mm)

|

0.07 - 0.2

|

|

|

|

|

|

|

|

|

|||||||||

|

Vertical permeability coefficient

(cm/s)

|

Kx(10-1 - 10-3)

|

|

|

|

|

|

|

|

|

|||||||||

|

Tear Strength

(KN≥)

|

0.08

|

0.12

|

0.16

|

0.2

|

0.24

|

0.28

|

0.33

|

0.38

|

0.42

|

|||||||||

|

Product specifications and performance parameters

|

|

|

|

|

|

|

|

|

|

|||||||||

|

Item

|

Nominal breaking strength/(kN/m)

|

|

|

|

|

|

|

|

|

|||||||||

|

|

3

|

5

|

8

|

10

|

15

|

20

|

25

|

30

|

40

|

|||||||||

|

Longitudinal and ransverse tracture strength (KN/m²)≥

|

3

|

5

|

8

|

10

|

15

|

20

|

25

|

30

|

40

|

|||||||||

|

Elongation corresponding to nominal breaking strength(%)

|

20-100

|

|

|

|

|

|

|

|

|

|||||||||

|

Breaking strength

(kN)≥

|

0.6

|

1

|

1.4

|

1.8

|

2.5

|

3.2

|

4

|

5.5

|

7

|

|||||||||

|

Mass deviation rate per unit

area(%)

|

±5

|

|

|

|

|

|

|

|

|

|||||||||

|

Width deviation rate(%)

|

-5

|

|

|

|

|

|

|

|

|

|||||||||

|

Thickness deviation rate(%)

|

±10

|

|

|

|

|

|

|

|

|

|||||||||

|

Equivalent pore size O35(O35)

(mm)

|

0.07-0.20

|

|

|

|

|

|

|

|

|

|||||||||

|

Vertical permeability coefficient

(cm/s)

|

Kx(10

-1

- 10

-3

)

K=1.0-9.9

|

|

|

|

|

|

|

|

|

|||||||||

|

Longitudinal and transverse tearing

strength(kN)≥

|

0.1

|

0.15

|

0.2

|

0.25

|

0.4

|

0.5

|

0.65

|

0.8

|

1

|

|||||||||

|

Acid and alkali resistance (strength retention rate

(%)

|

80

|

|

|

|

|

|

|

|

|

|||||||||

|

Antioxidant performance strength retention rate

(%)

|

80

|

|

|

|

|

|

|

|

|

|||||||||

|

UVresistance strength retention

rate(%)

|

80

|

|

|

|

|

|

|

|

|

|||||||||

High quality raw materials

Raw materials are acid and alkali resistant, non corrosive, and non insect infested

water permeability

The product has good water permeability and is particularly suitable for coastal swamps and landfill sites.

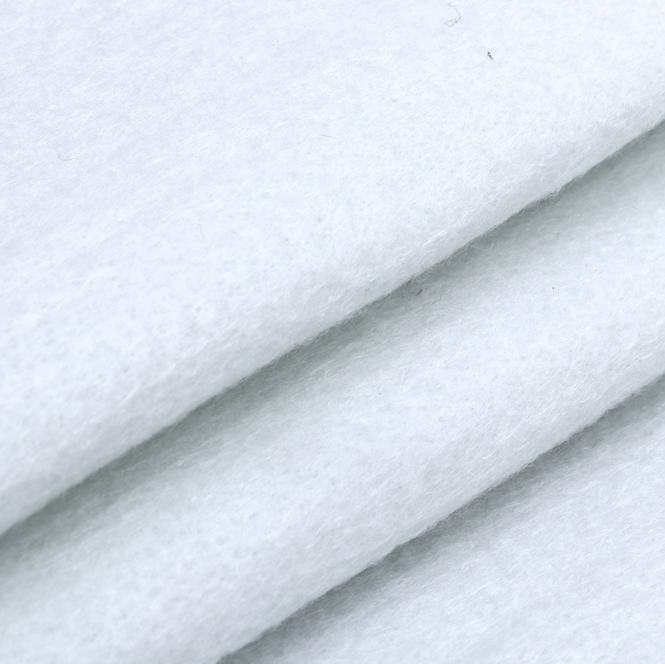

Lightweight

Lightweight and easy to construct, it can be widely used for filtration, drainage, protection, reinforcement, etc. in railway, highway, sports hall and other engineering projects

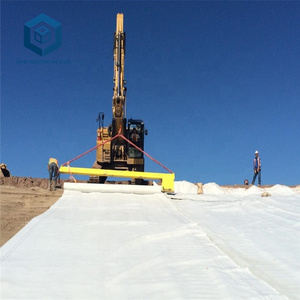

Construction cases

shipment

Hot Searches