- Product Details

- {{item.text}}

Quick Details

-

Power (kW):

-

22

-

Weight (KG):

-

1600

-

Product name:

-

Sheet Metal Deburring Machine

-

Application:

-

Metal Deburring

-

Machine Type:

-

Deburring Polishing Machine

-

Raw material:

-

Steel Material

-

Advantage:

-

High Working Efficiency

-

Voltage:

-

380V 50Hz 3Phase/Customized

-

Usage:

-

All flat metal

-

Processing width:

-

600mm, 800mm, 1000mm, 1300mm 1600mm

-

Processing thickness:

-

0.5-100mm

-

Control system:

-

Plc

Quick Details

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Hokang

-

Marketing Type:

-

Hot Product

-

Power (kW):

-

22

-

Weight (KG):

-

1600

-

Product name:

-

Sheet Metal Deburring Machine

-

Application:

-

Metal Deburring

-

Machine Type:

-

Deburring Polishing Machine

-

Raw material:

-

Steel Material

-

Advantage:

-

High Working Efficiency

-

Voltage:

-

380V 50Hz 3Phase/Customized

-

Usage:

-

All flat metal

-

Processing width:

-

600mm, 800mm, 1000mm, 1300mm 1600mm

-

Processing thickness:

-

0.5-100mm

-

Control system:

-

Plc

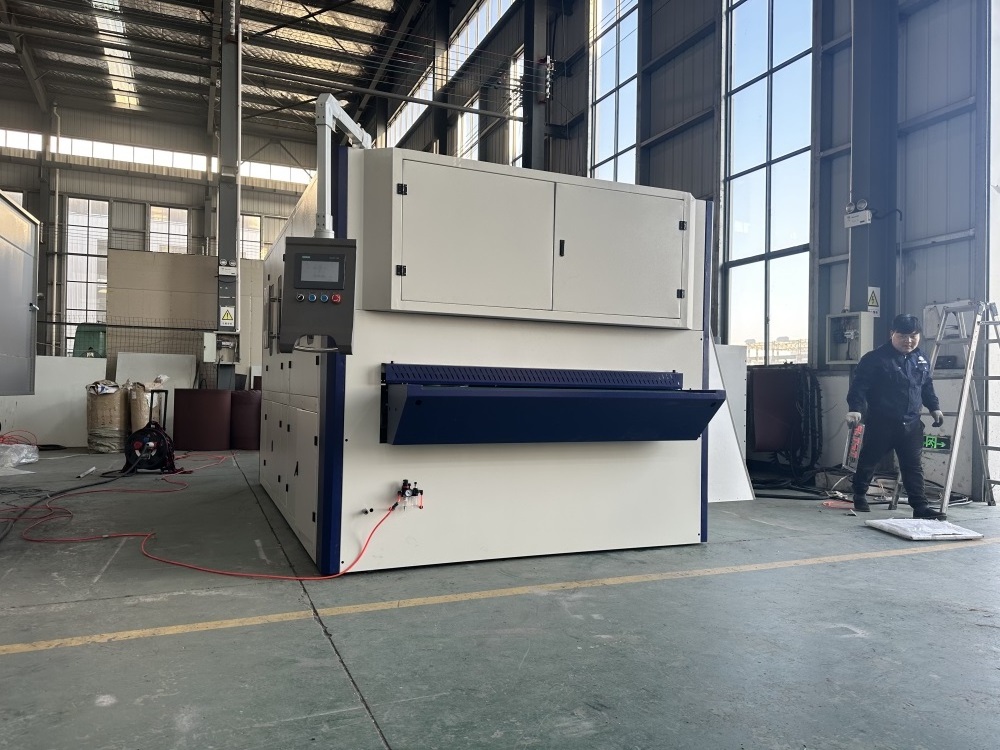

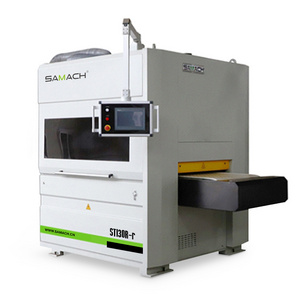

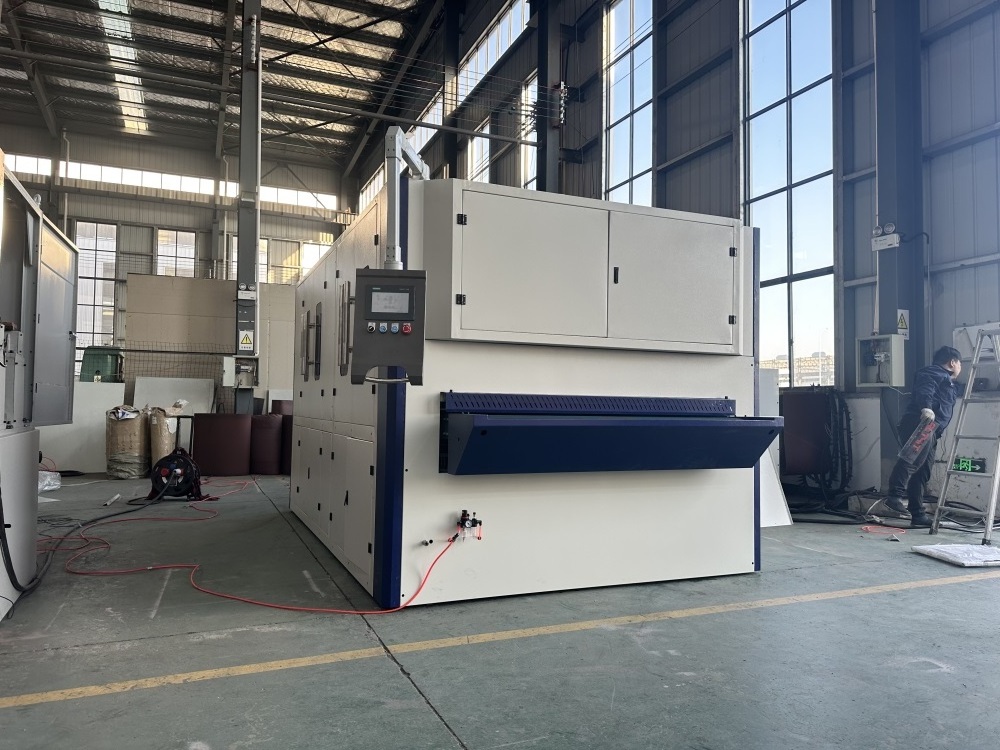

Products Overview

Multi-function Flat Sheet Metal Deburring Machine Metal Polishing and Grinding Machine

This equipment is suitable for carbon steel plate, stainless steel plate, copper plate, etc.,

Adjust the corresponding grinding parameters and select the appropriate abrasive according to the different surface requirements of the workpiece.

Adjust the corresponding grinding parameters and select the appropriate abrasive according to the different surface requirements of the workpiece.

Specification

|

No

|

Item

|

Data

|

|

1

|

Effective processing width

|

600mm, 800mm, 1000mm, 1300mm, 1600mm

|

|

2

|

Processing thickness

|

0.5-100 mm

|

|

3

|

Feeding speed

|

0.5-9 m/min

|

|

4

|

Abrasive belt size

|

1900x650mm

|

|

5

|

Control Systems

|

Plc

|

|

6

|

Power supply

|

380V/50Hz

|

The specific parameters of the product are determined according to the functions you choose. The equipment mainly has four functions:

deburring

,

polishing

,

chamfering

, and

wire

drawing

. Various model combinations can be provided according to customer requirements.

1. Double abrasive belt model, wire drawing, polishing, scale removal, deburring

2. Abrasive belt + universal roller combination model, deburring and chamfering

3. Abrasive belt + universal roller + abrasive belt, deburring, chamfering, wire drawing

4. Diamond hammer + abrasive belt + universal roller, slag removal, burr removal, and R-angle chamfering

5. Horizontal sanding belt + sand block, deburring and chamfering

6. Abrasive belt + disc brush, deburring and chamfering

Design of Machine

This machine tool mainly consists of the frame part, the abrasive belt part, the conveying workbench, the CNC control system, etc.:

1. Rack:

This component consists of low frame, upper frame, sand belt frame, workbench, etc., forming a frame frame. The steel plate of the whole machine is welded, and the gantry is processed and milled in the center to maintain high-precision flatness of the equipment.

2. Abrasive belt principle:

The deburring mechanism of this equipment is a wide abrasive belt structure. The abrasive belt mechanism is arranged in a wide and longitudinal direction. It adopts a lifting and abrasive belt deflection mechanism. It can easily perform high-precision drawing, punching and curling of hard burrs on the surface of the workpiece.

3. Principle of roller brush:

The grinding mechanism of this equipment is a roller brush mechanism. The two rows of roller brushes of the roller brush mechanism are placed in parallel. Driven by the revolution axis, each roller brush rotates at high speed and beats the workpiece, effectively removing the sharp edges of the surface contour of the workpiece, forming a Smooth and beautiful chamfer effect.

4. Principle of drawing and polishing roller:

The drawing and polishing mechanism is arranged in a wide longitudinal direction and adopts a lifting mechanism, which can easily draw and polish the workpiece surface with high precision.

5. Principle of conveying mechanism:

This equipment is driven by a high-damping conveyor belt, and the conveying speed is adjustable with frequency conversion. It uses pressure roller clamping, electromagnetic suction cup adsorption, and high-pressure vacuum adsorption functions to transport workpieces fixedly, and is suitable for polishing plate workpieces of various shapes.

Product Features

1.The surface is deburred and finished, and the abrasive belt can be changed at will.The mesh number of the product will change accordingly.

2.It is suitable for the removal of burrs in the holes of sheet metal parts on the same plane or relative to the same plane by CNC punching and shearing machines; the removal of burrs generated after laser cutting; the removal of slag generated by flame cutting or plasma cutting, etc.

3.Replace the burrs with files, scrapers, or use electric and pneumatic tools for grinding process solutions, so that the workpiece can be polished more evenly; it is safer, and it can effectively reduce labor costs and improve production efficiency.

4.The equipment adopts Chint button system, which is simple and convenient to operate, and the thickness digital display can be electrically upgraded and fine-tuned, which is convenient and quick to adjust the grinding amount.

5.This machine uses common consumables in the market, and imported sandpaper can also be customized to improve production efficiency and meet special requirements of products.

6.The equipment is equipped with a dust collector interface to suck away the dust, metal shavings and dust generated during the working process of the equipment. You can choose a separate dust removal equipment or link the existing equipment in the factory

Finished Product

Stainless steel

Aluminum

Iron

Copper

Hot Searches