- Product Details

- {{item.text}}

Quick Details

-

Applicable Industries:

-

Industrial heating furnace

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

SYN

-

Dimension(L*W*H):

-

CUSTOMED

-

Weight:

-

KG

-

Working Temperature Range:

-

500 - 1100 custom℃

-

Core Components:

-

Resistance Wire

-

Certificate:

-

ROHS

-

Package:

-

Wooden Case

-

Raw material:

-

Ceramic Fibre Bulk

-

Size:

-

300*300*150 ~300mm

-

Density:

-

96-280

-

Shrinkage(%):

-

0.5-1 (1350℃*24h)

-

Color:

-

Pure White

-

Product name:

-

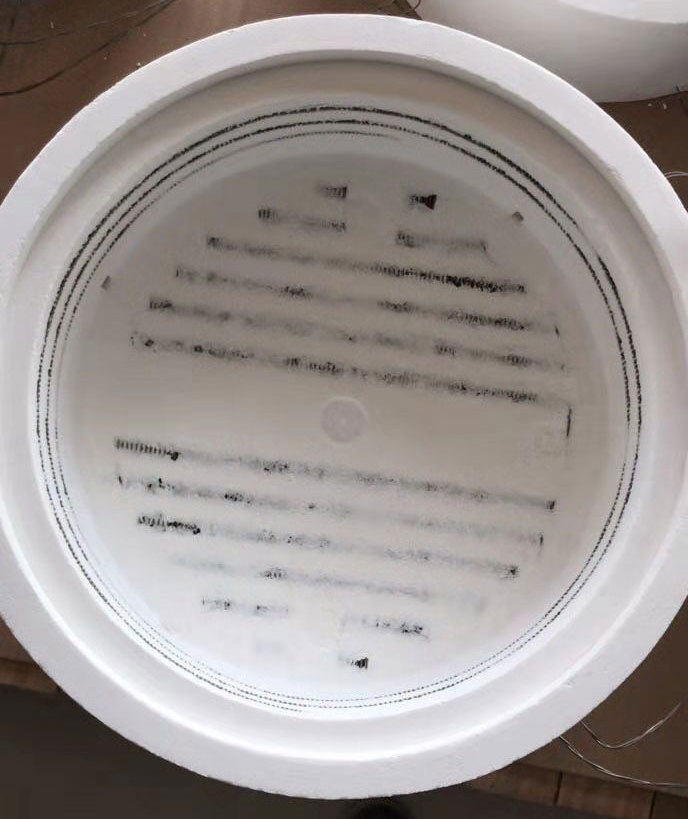

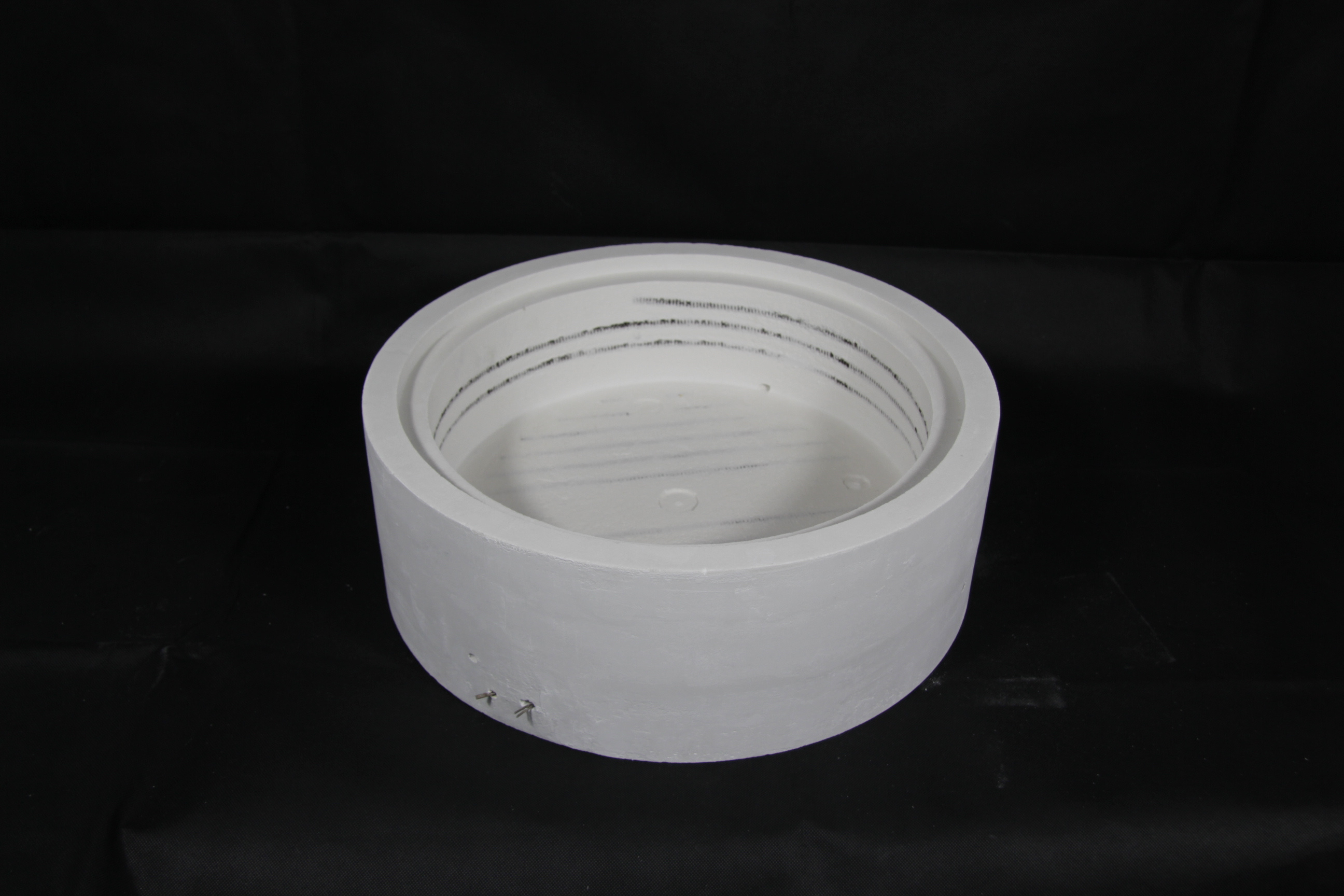

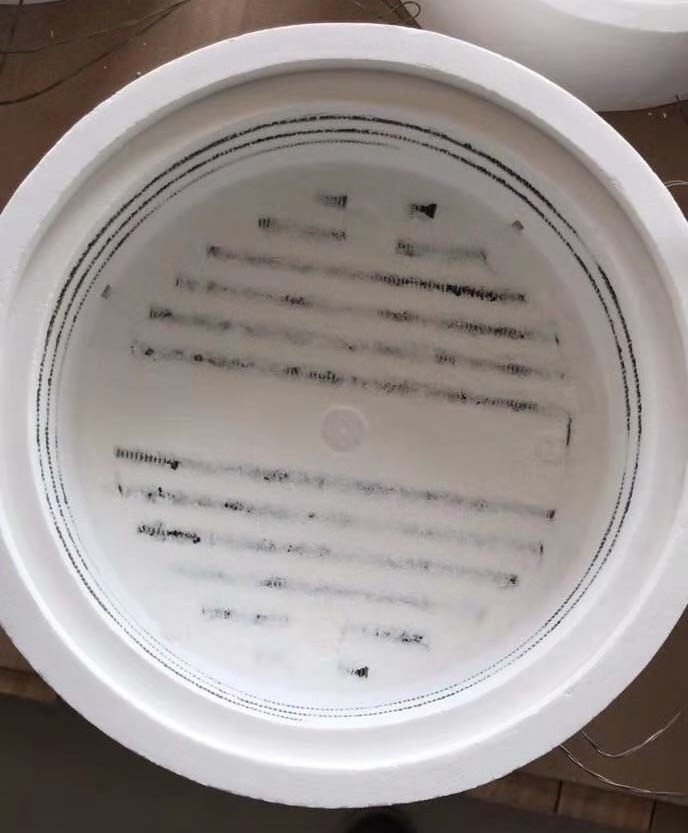

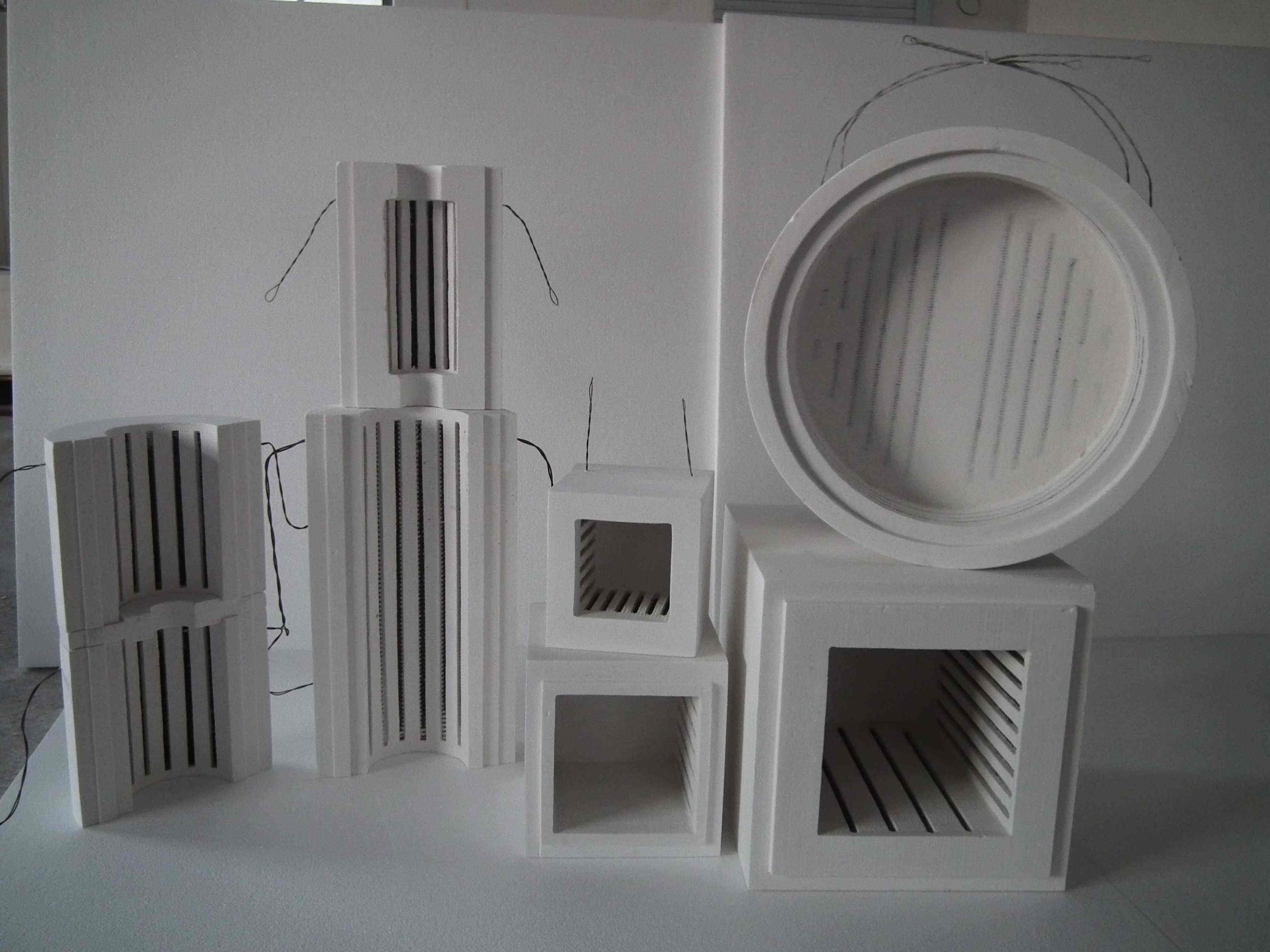

Ceramic Fiber Vaccum Formed Shaped Heater for Crucible Furnace

-

Working temperature:

-

1400 Degree

-

Thermal conductivity(w/mk):

-

45W/m.k(1200 )

-

After Warranty Service:

-

Video technical support, Online support

-

Local Service Location:

-

Canada, Turkey, United Kingdom, United States, Italy, France, Germany, Viet Nam, Philippines, Brazil, Peru, Saudi Arabia, Indonesia, Pakistan, India, Mexico, Russia, Spain, Thailand, Japan, Malaysia, Australia, UAE, Colombia, Sri Lanka, Romania

-

Showroom Location:

-

Canada, Turkey, United Kingdom, United States, Italy, France, Germany, Viet Nam, Philippines, Brazil, Peru, Saudi Arabia, Indonesia, Pakistan, India, Mexico, Russia, Spain, Thailand, Morocco, Kenya, Argentina, South Korea, UAE, Colombia, Sri Lanka, Romania, Malaysia, Australia

-

After-sales Service Provided:

-

Video technical support, Online support

-

Marketing Type:

-

Ordinary Product

-

Certification:

-

RoHS

Quick Details

-

Type:

-

Air Heater

-

Power Source:

-

Electric

-

Voltage:

-

220v

-

Applicable Industries:

-

Industrial heating furnace

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

SYN

-

Dimension(L*W*H):

-

CUSTOMED

-

Weight:

-

KG

-

Working Temperature Range:

-

500 - 1100 custom℃

-

Core Components:

-

Resistance Wire

-

Certificate:

-

ROHS

-

Package:

-

Wooden Case

-

Raw material:

-

Ceramic Fibre Bulk

-

Size:

-

300*300*150 ~300mm

-

Density:

-

96-280

-

Shrinkage(%):

-

0.5-1 (1350℃*24h)

-

Color:

-

Pure White

-

Product name:

-

Ceramic Fiber Vaccum Formed Shaped Heater for Crucible Furnace

-

Working temperature:

-

1400 Degree

-

Thermal conductivity(w/mk):

-

45W/m.k(1200 )

-

After Warranty Service:

-

Video technical support, Online support

-

Local Service Location:

-

Canada, Turkey, United Kingdom, United States, Italy, France, Germany, Viet Nam, Philippines, Brazil, Peru, Saudi Arabia, Indonesia, Pakistan, India, Mexico, Russia, Spain, Thailand, Japan, Malaysia, Australia, UAE, Colombia, Sri Lanka, Romania

-

Showroom Location:

-

Canada, Turkey, United Kingdom, United States, Italy, France, Germany, Viet Nam, Philippines, Brazil, Peru, Saudi Arabia, Indonesia, Pakistan, India, Mexico, Russia, Spain, Thailand, Morocco, Kenya, Argentina, South Korea, UAE, Colombia, Sri Lanka, Romania, Malaysia, Australia

-

After-sales Service Provided:

-

Video technical support, Online support

-

Marketing Type:

-

Ordinary Product

-

Certification:

-

RoHS

Product Description

Specification

|

Type

|

|

SYN-1500Y

|

SYN-1600Y

|

SYN-1700Y

|

SYN-1800Y

|

SYN-1900Y

|

|

|

Classification Temperature(C)

|

|

1500

|

1600

|

1700

|

1800

|

1900

|

|

|

Working Temperature(C)

|

|

1350

|

1500

|

1600

|

1700

|

1780

|

|

|

Density(kg/³m)

|

|

300-400

|

400

|

350-400

|

400-500

|

600-700

|

|

|

Shrinkage(%)

|

|

1400℃*24h

-1.5 |

1500℃*24h

-0.5 |

1600℃*24h

-0.5 |

1500℃*24h

-0.20 |

1500℃*24h

+0.1~-0.2 |

|

|

Thermal

conductivity (w/mk) |

400C

|

-

|

-

|

-

|

-

|

-

|

|

|

|

600C

|

0.12

|

-

|

-

|

-

|

-

|

|

|

|

800C

|

0.16

|

0.14

|

0.15

|

0.17

|

0.2

|

|

|

|

1000C

|

0.23

|

0.17

|

0.19

|

0.24

|

0.3

|

|

|

|

1200C

|

0.25

|

0.23

|

0.25

|

0.28

|

0.33

|

|

Application:

1.Insulation for high-temperature furnaces.

2.Surface insulation of industrial kilns.

3.Fire-barrier material for the multi-temperature-zones furnace.

4.Backing insulation of petroleum, chemical, and metallurgical furnace.

5. High-temperature sintering sagger.

6.High temperature sealing for machine and precision mold.

2.Surface insulation of industrial kilns.

3.Fire-barrier material for the multi-temperature-zones furnace.

4.Backing insulation of petroleum, chemical, and metallurgical furnace.

5. High-temperature sintering sagger.

6.High temperature sealing for machine and precision mold.

Here is the real case we have done

Project 4. We are the first company at home to recombine 1400 ceramic fiber modules and boards to make the new type of vacuum sintering furnace.

Hot Searches