- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

BRD

-

Model Number:

-

PU Cold Room Panel

-

Product name:

-

FM Approved Polyurethane pur pir Sandwich Panels ForClean Room

-

Steel Thickness:

-

0.4-0.7mm

-

Core Thickness:

-

50-200mm

-

Material:

-

Galvanzied Steel

-

Core material:

-

Hard Polyurethane Foam

-

Length:

-

11.8m

-

Density:

-

40-42kg/m3

-

Zero Risk Commitment:

-

Can be return in 15 Days/Exchanged in 3 Mouths /Warranty in 3 Years

-

Cooperation Policy:

-

Recruited a Global Agent

Quick Details

-

Project Solution Capability:

-

graphic design, 3D model design, total solution for projects, Cross Categories Consolidation

-

Application:

-

Warehouse

-

Design Style:

-

Industrial

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

BRD

-

Model Number:

-

PU Cold Room Panel

-

Product name:

-

FM Approved Polyurethane pur pir Sandwich Panels ForClean Room

-

Steel Thickness:

-

0.4-0.7mm

-

Core Thickness:

-

50-200mm

-

Material:

-

Galvanzied Steel

-

Core material:

-

Hard Polyurethane Foam

-

Length:

-

11.8m

-

Density:

-

40-42kg/m3

-

Zero Risk Commitment:

-

Can be return in 15 Days/Exchanged in 3 Mouths /Warranty in 3 Years

-

Cooperation Policy:

-

Recruited a Global Agent

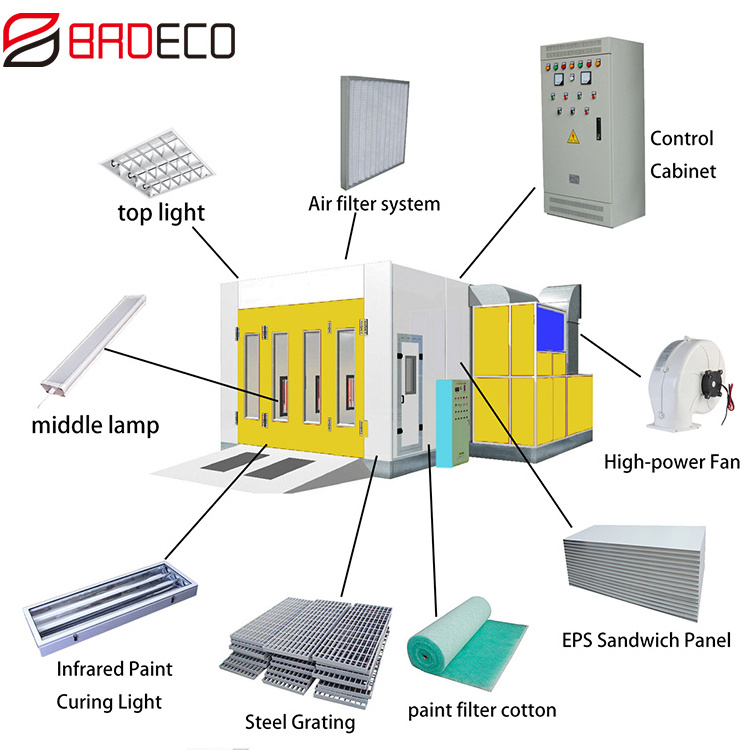

Product Description

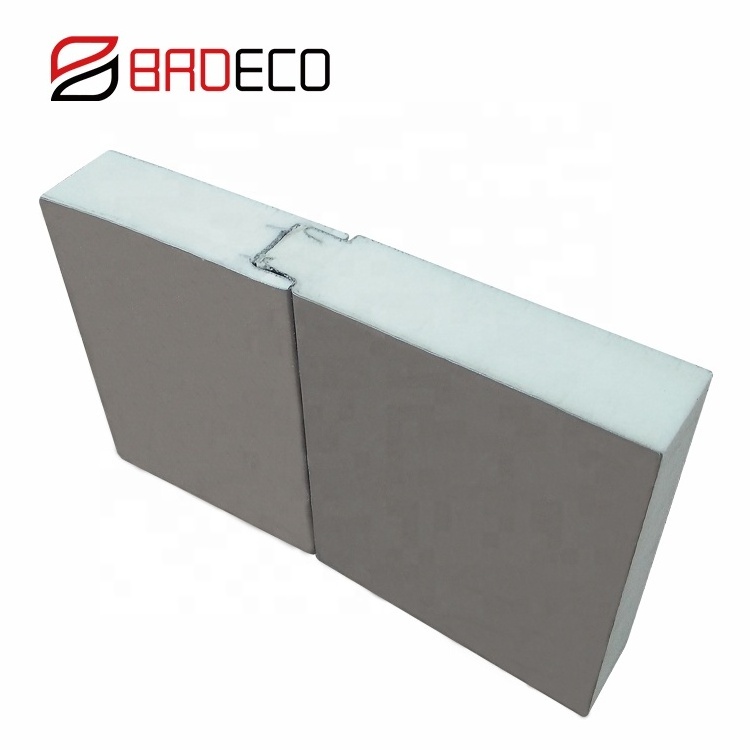

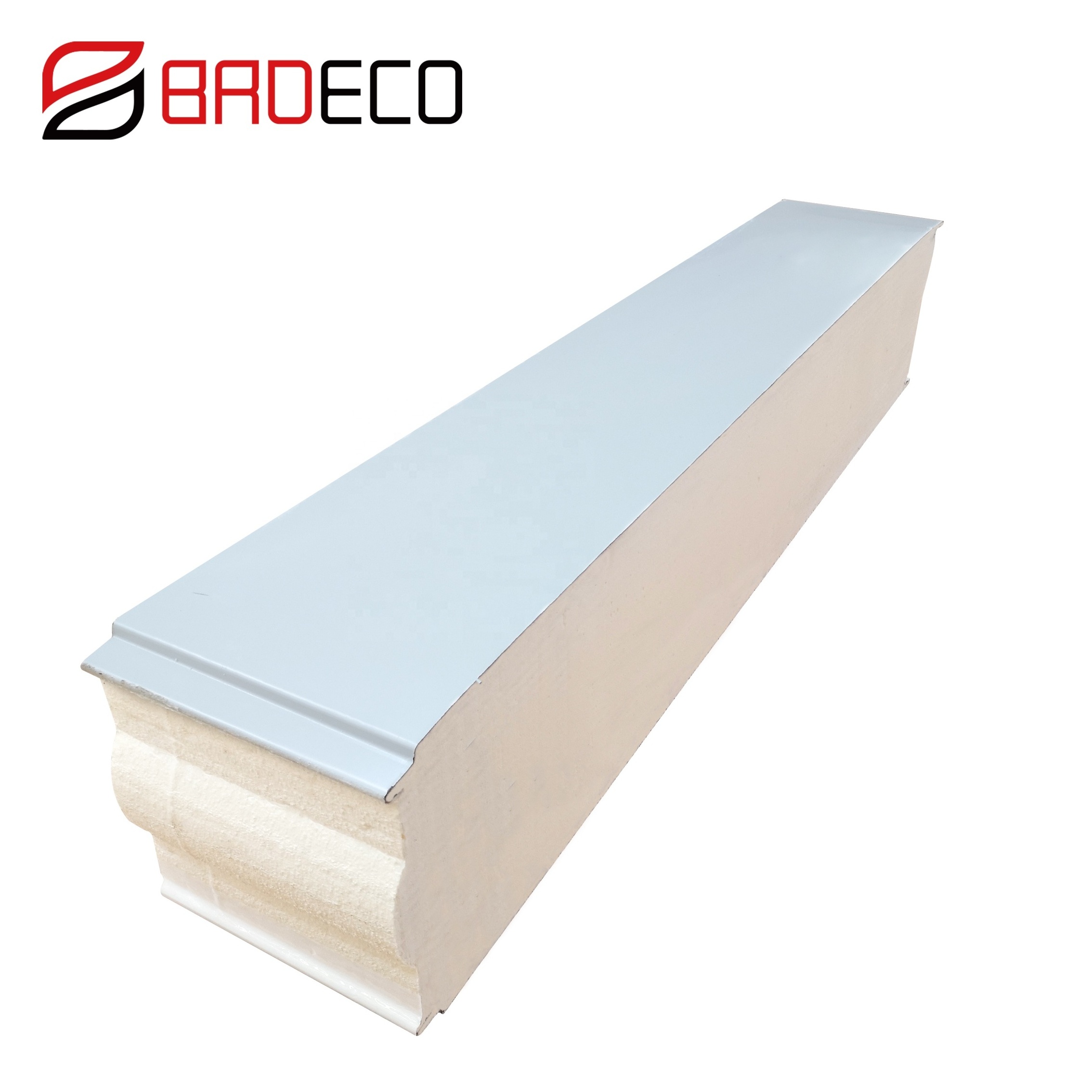

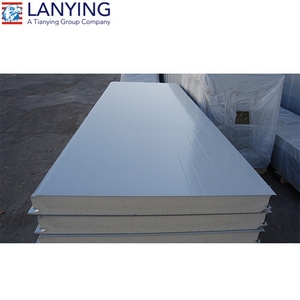

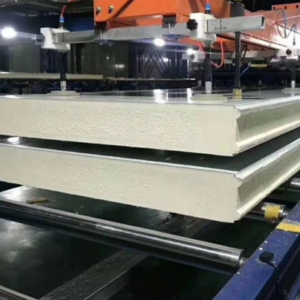

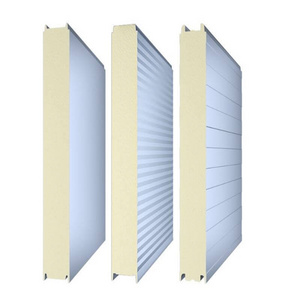

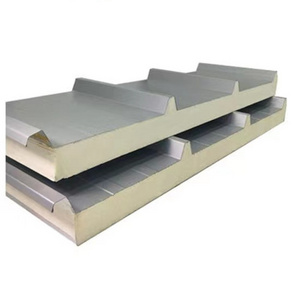

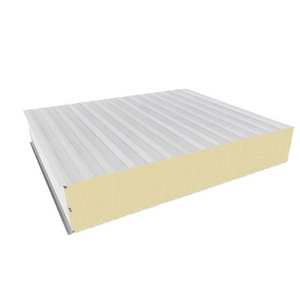

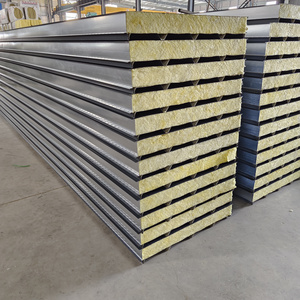

The polyurethane cold room panel is composed of two galvanized stee sheets and rigid polyurethane foam in the middle. Because the polyurethane cold room panel has several outstanding advantages, such as thermal insulation, waterproof, light weight and fast installation, It has been widely used as the building material of cold storages, cool rooms, clean rooms, free-dust workshops and exterior walls in cold places.

At present, BRD polyurethane cold room panel has five different thickness: 50mm, 75mm, 100mm, 150mm, 200mm.

|

|

Length(m)

|

|

less than 30m

|

|

|||

|

|

Width(mm)

|

|

960mm

|

|

|||

|

|

Thickness(mm)

|

|

50, 75 ,100 ,120 ,150 ,200mm

|

|

|||

|

Heat Conductivity(W/mk)

|

|

|

0.022

|

|

|||

|

Compressive Strength(N/cm2)

|

|

|

more than 196

|

|

|||

|

Tensile Strength (N/cm2)

|

|

|

more than 24.5

|

|

|||

|

Bending Strength (N/cm2)

|

|

|

more than 24.5

|

|

|||

|

Water Absorption(g/100cm2)

|

|

|

3

|

|

|||

|

Flame Resistance

(only for panels added flame retardant agent)

|

|

|

Self-extinguishing within 3 seconds after taking away flame

|

|

|||

|

|

|

|

Color painted steel

Stainless steel Galvanized steel |

|

|||

Specification

1、Energy-saving insulation

Excellent thermal insulation performance(average heat transfer coefficient as 0.20W/m.k). the protective effect of formula with stable and the outer layer of color plates, in three years, its thermal performance remains in its initial thermal insulation efficiency 95% for 180 days. The core of obturator rate greater than 97%

2、Green environmental protection

The foaming process of polyurethane sheet with anticyclone as foam foaming agent of polyurethane rigid foam model, through high pressure foaming, so that products meet the international convention for the protection of the ozone layer, and in line with European environmental standards.Does not contain formaldehyde, not subject to microbial attack..

3、Fire resistance

Have excellent fireproof performance, by the national fireproof construction material quality supervision inspection center testing, the indicators of GB8624B1 level.Belongs to a thermos setting materials, burning carbonation to ashes, from the fire self-extinguishing, not falling, not spread.

4、Fast construction

Factory production ,the constant temperature environment quality is stable, fast to install.

Machine Made Cold Room Panel

Camlock Cold Room Panel

Cold room panel is a new building material for cold storages and other buildings in cold places. It performs outstanding in aspects of thermal insulation and the waterproof, so it is widely accepted as a wonderful insulation building material. It is composed of two galvanized steel sheets and rigid polyurethane foam in the middle.

Hot Searches