- Product Details

- {{item.text}}

Quick Details

-

Filling Accuracy:

-

0.5% (liquid Level)

-

Voltage:

-

220V/380V 50-60HZ, Customized

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

Ipack

-

Dimension(L*W*H):

-

2000*1050*1600

-

Weight:

-

6000 KG

-

Material:

-

SUS304 / 316L

-

Filling Product:

-

Fruit Juice / Tea Drink

-

Bottle Volume:

-

200ml - 2L

-

Filling Precision:

-

1% (Liquid Level)

-

Capacity:

-

2000bph - 24000bph

-

Bottle Material:

-

Pet Bottle / Glass Bottle

-

Function:

-

Rinsing Filling Capping

-

Control:

-

PLC (Siemens)

-

Certification:

-

CE, ISO

Quick Details

-

Machinery Capacity:

-

4000BPH, 8000BPH, 12000BPH, 6000BPH, 20000BPH, 16000BPH, 2000BPH, Other

-

Packaging Material:

-

Plastic, Glass

-

Filling Material:

-

Beer, Milk, Water, Oil, Juice, Powder, Other

-

Filling Accuracy:

-

0.5% (liquid Level)

-

Voltage:

-

220V/380V 50-60HZ, Customized

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

Ipack

-

Dimension(L*W*H):

-

2000*1050*1600

-

Weight:

-

6000 KG

-

Material:

-

SUS304 / 316L

-

Filling Product:

-

Fruit Juice / Tea Drink

-

Bottle Volume:

-

200ml - 2L

-

Filling Precision:

-

1% (Liquid Level)

-

Capacity:

-

2000bph - 24000bph

-

Bottle Material:

-

Pet Bottle / Glass Bottle

-

Function:

-

Rinsing Filling Capping

-

Control:

-

PLC (Siemens)

-

Certification:

-

CE, ISO

Products Description

We supply complete solution for the juice filling machine ,including Water treatment system /Juice mixing system / UHT Sterilizer/ Washing filling capping machine / Code sprayer / Automatic labeling machine / Automatic packing machine / Automatic Palletizer system

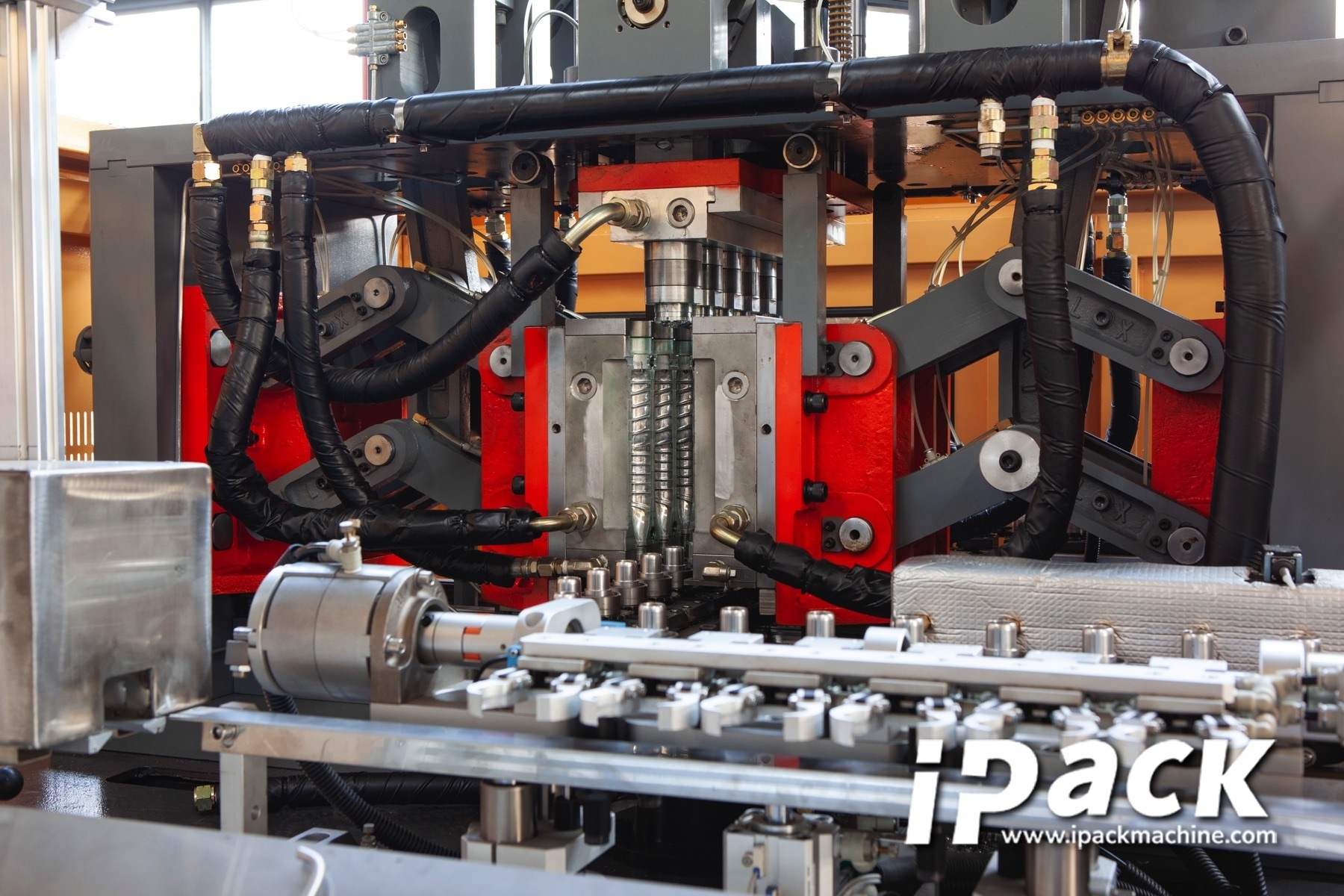

1. Bottle Blowing Part

Less bottle cost/Stable working/High bottle performance

Bottle blowing machine is to make plastic bottles for mineral water, carbonated drink, juice and so on. It is widely used in the food and beverage package industry.

2. Water Treatment Part

Simple operation/Less maintenance/Lower power consumption

According to customer's raw water analysis report and the final water standard request, we will suggest customer to choose the suitable water treatment plant.

3. Juice Processing System

Complete juice processing system with reasonable mixing and sterilization technology ,not only can be suitable for common products, but also can satisfy special requirements of customers ,for example juice ,milk ,cream or high viscosity products containing fiber and large pulp granules .

4. Washing Filling Capping Machine

High filling accuracy/Famous components/Stainless steel material

This machine is mainly used in the juice drink filling operations. The three functions of bottle rinsing, filling and capping are composed in one body of the machine. The machine is used in filling fruit juice and tea drink in bottles made of glass and plastics. The handle of the machine can be freely and conveniently turned to adjust the machine to fill various types of bottles. The advanced Mitsubishi programmed controller (PLC) is adopted to control of the machine to run automatically while a transducer is used in the bottle-entering chains to adjust speed and coordinated with the transducer of the main machine to make the operations of moving bottle forward steadily and reliably. The aluminum theft proof cap and plastic cap can be adopted. The machine is an idea-preferred equipment for beverage manufacturers.

|

Technical Parameter

|

|

|

|

|

|

|||||

|

Model

|

RCGF14-12-5

|

RCGF18-18-6

|

RCGF24-24-8

|

RCGF32-32-8

|

RCGF40-40-10

|

|||||

|

Capacity

|

2000-3000

|

6000-8000

|

8000-12000

|

12000-15000

|

18000-20000

|

|||||

|

Bottle shapes

|

PET circular

|

|

|

|

|

|||||

|

Bottle diameter

|

Dia50-Dia115mm

|

|

|

|

|

|||||

|

Bottle height

|

160-320mm

|

|

|

|

|

|||||

|

Filling type

|

Hot filling

|

|

|

|

|

|||||

|

Filling pressure

|

<0.4 Mpa

|

|

|

|

|

|||||

|

Rinsing pressure

|

>0.06Mpa <0.2Mpa

|

|

|

|

|

|||||

|

Application

|

energy drink filling machine

|

|

|

|

|

|||||

|

Motor power

|

4.4kw

|

5.2kw

|

6.2kw

|

7.5kw

|

8.2kw

|

|||||

|

Overall dimensions

|

2.5*1.9m

|

2.8*1.9m

|

3.2*2.2m

|

3.4*2.5m

|

4.8*2.3m

|

|||||

|

Height

|

2.3m

|

2.5m

|

2.5m

|

2.5m

|

2.5m

|

|||||

|

Weight

|

3000kg

|

4500kg

|

6000kg

|

8500kg

|

10000kg

|

|||||

UHT juice filling line Main Features

*Using the wind sent access and move wheel in the bottle directly connected technology; canceled screw and conveyor chains, this enable the change the bottle-shaped become easier.

* Bottles transmission adopt clip bottleneck technology, bottle-shaped transform not need to adjust the equipment level, only change related the curved plate, wheel and nylon parts is enough..

* The specially designed stainless steel bottle washing machine clip is solid and durable, no touch with the screw location of bottle mouth to avoid secondary pollution.

*High-speed large hot filling valve, filling fast, filling accurate and no liquid lose.

*Spiraling decline when output bottle, transform bottle shape no need to adjust the height of conveyor chains.

*Host adopt advanced PLC automatic control technology, the key electrical components from famous company such as Japan's Mitsubishi, France Schneide, OMRON.

*Using the wind sent access and move wheel in the bottle directly connected technology; canceled screw and conveyor chains, this enable the change the bottle-shaped become easier.

* Bottles transmission adopt clip bottleneck technology, bottle-shaped transform not need to adjust the equipment level, only change related the curved plate, wheel and nylon parts is enough..

* The specially designed stainless steel bottle washing machine clip is solid and durable, no touch with the screw location of bottle mouth to avoid secondary pollution.

*High-speed large hot filling valve, filling fast, filling accurate and no liquid lose.

*Spiraling decline when output bottle, transform bottle shape no need to adjust the height of conveyor chains.

*Host adopt advanced PLC automatic control technology, the key electrical components from famous company such as Japan's Mitsubishi, France Schneide, OMRON.

5. Lebeling Machine

High precision/High speed

There are mainly three kinds labeling machine, PVC sleeve shrink labeling machine, pressure sensitive sticker labeling machine and OPP hot glue labeling machine.

6. Packaging Machine

Better design for final package solution, more choice for label material

There are mainly two kinds of case packing machine, film shrink wrapping machine and carton packing machine. For film shrink wrapping machine, there is also with for unprinted film and for printed film, then there is also shrink film with carton tray. For carton packing machine, there is tape sealing type and hot glue sealing type.

7. Conyeyor System Part

Energy save/Automatic lubricant system/Space save

We design the factory layout based on customer factory sizes, whole line design is based on famous brand motors and automatic lubricant system, with less power consumption and space.

Hot Searches